Ensuring Painting and Coating Excellence in Industrial Environments with Desiccant Dehumidification

By Staff Report June 12, 2025 12:29 pm IST

Moisture control is critical for the success of painting and coating applications in industrial settings. Desiccant dehumidification technology ensures optimal surface conditions, prevents corrosion, and enhances coating longevity, ultimately improving operational efficiency and reducing downtime across facilities.

The role of a coating system is indispensable in an industrial setup, as it determines the efficacy of critical processes carried out within the facility. However, even the slightest trace of moisture in the plant can compromise operations, necessitating the deployment of desiccant dehumidifiers to create ideal environmental conditions. These systems are essential for maintaining humidity at optimal levels to ensure uninterrupted process execution.

The importance of desiccant dehumidifiers becomes evident considering that humidity can deteriorate the coating system. Coating provides a protective layer to tanks, and moisture significantly reduces its lifespan. By preventing proper adhesion between the substrate and the coating, moisture leads to failures in critical operations. Therefore, efficient surface preparation is a prerequisite to ensure effective coating of cold-water ducts, cooling towers, FGD stack linings, absorbers, and rubber linings in acid tanks. Inadequate surface preparation can result in blistering, cracking, peeling, and cratering, ultimately causing premature failure of the coating system. Improper coating also affects highly sensitive and reactive chemicals stored in tanks, as it causes surface wear, leading to contamination and dilution of petrochemicals, chemical gases, and more.

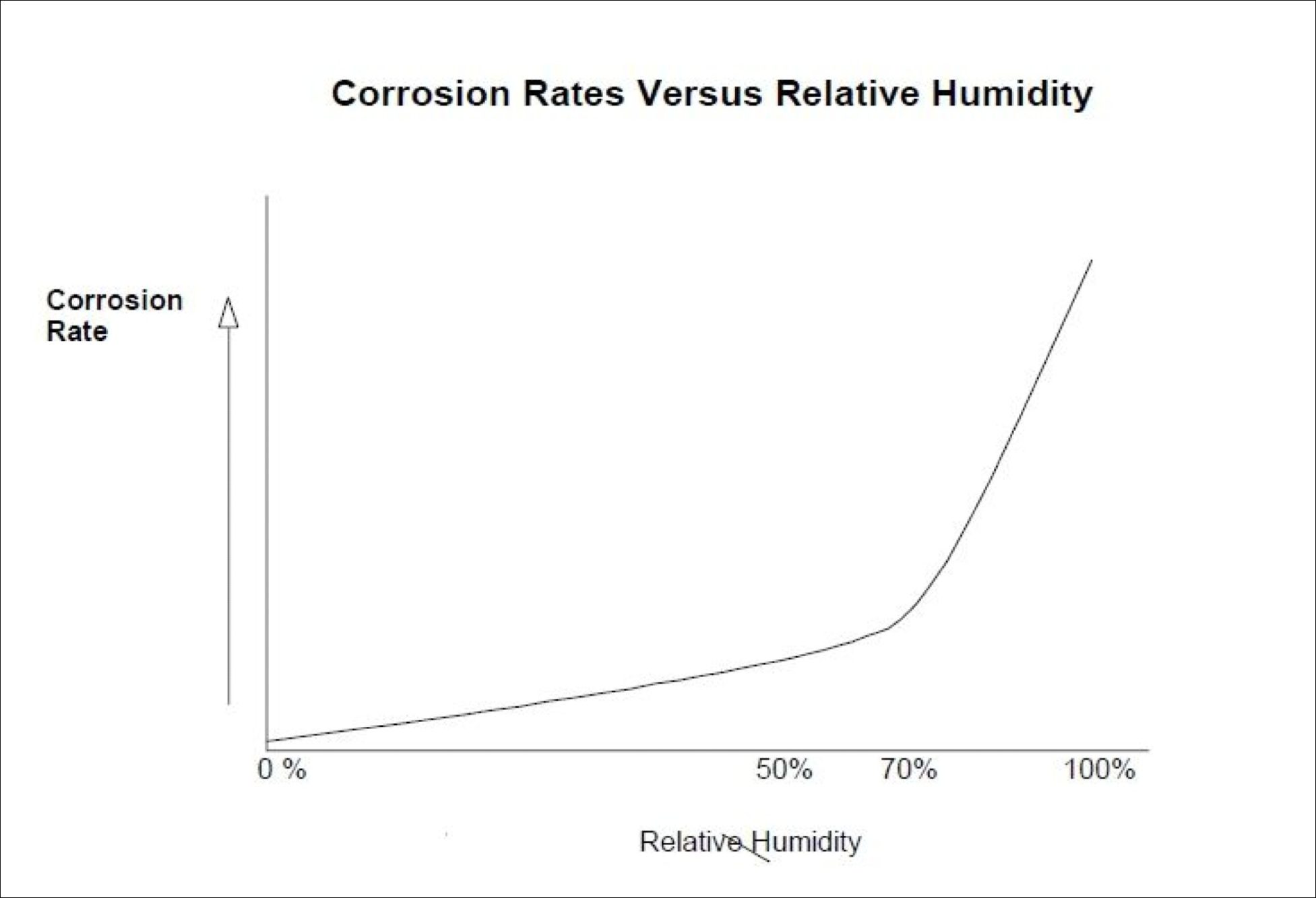

Monsoon conditions and night-time temperatures worsen the problem due to the prevalence of cold weather, which increases moisture levels in the air. This leads to condensation on metal surfaces, initiating corrosion known as ‘flash rust’ or ‘rust bloom’. Given the severe impact of moisture on the efficiency and profitability of power plants, employing desiccant dehumidification technology becomes crucial to eliminate moisture from the facility. It proves effective in monitoring temperature, relative humidity (RH), and dew point, thereby ensuring comprehensive industrial coating by keeping humidity within a tightly controlled range.

Desiccant dehumidifiers are equipped with advanced technologies that support proper surface preparation for effective coating application. This helps prevent condensation and resists rust bloom during blasting and painting operations. The technology plays a key role in preventing curing failure by eliminating surface blistering. Additionally, it enables anti-corrosive painting and enhances intercoat adhesion, increasing the coating lifespan by 1.5 to 2 times and exceeding standard expectations.

These dehumidifiers maintain temperatures between 30°C and 35°C while achieving relative humidity levels below 55% inside tanks throughout blasting, painting, and coating jobs. They also maintain a constant -5°C dew point differential between air and surface temperature and a -12°C differential between the air inside the tank or silo and the external atmosphere.

Beyond controlling humidity for effective coating, dehumidifiers offer easy and cost-effective solutions. They contribute to cost savings of up to 2–4% of the total expense that would otherwise be incurred in corrosion-preventive painting. They also allow for year-round blasting, painting, and coating by maintaining ideal indoor conditions regardless of external weather. Their efficiency in regulating conditions at night further helps reduce unplanned power plant downtime caused by unfavourable weather.

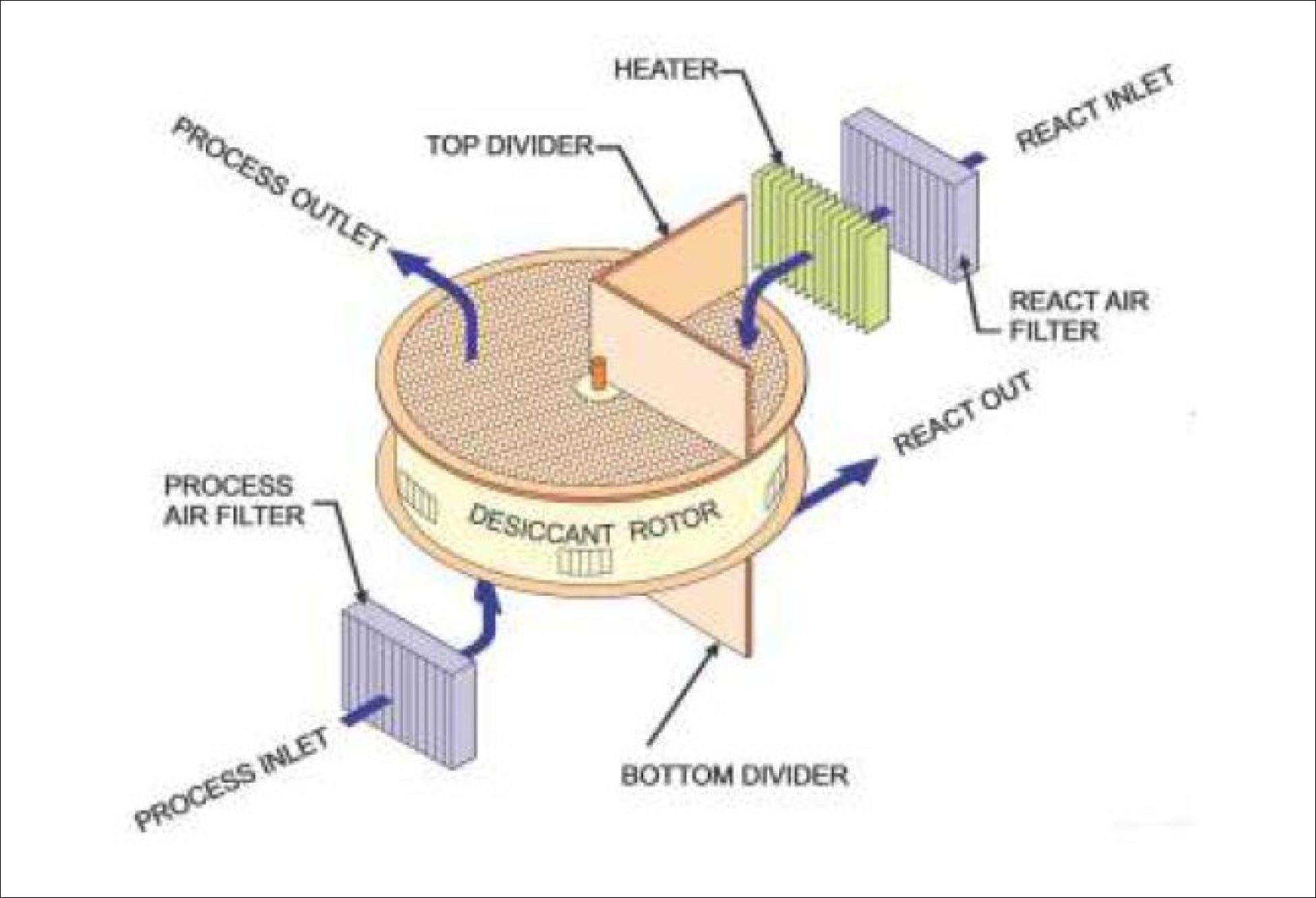

Desiccant Dehumidification Operating Principle

As a result, these systems promote timely project completion and reduce overall costs by up to 35%. They enable on-time delivery and lower project expenses. Without dehumidifiers, blasting and painting would need to be performed in phases to avoid condensation between processes. This complicates the workflow, making it impractical and time-consuming, resulting in increased costs. In contrast, desiccant dehumidifiers support continuous blasting and painting in a single operation, offering an economical solution for power plants.

Their benefits also extend to preserving electromechanical equipment by ensuring its longevity and performance. Additionally, they assist in concrete drying and help maintain controlled relative humidity in control rooms, preventing equipment malfunctions and supporting optimal operations.

With these advantages, the deployment of desiccant dehumidifiers across industrial facilities is essential. By addressing moisture-related threats, they extend the life of the coating system, support the efficiency of related processes, and ultimately boost the productivity of the plant.

Authored by, Atul Bansal, Chief Operating Officer, Technical Drying Services

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.