Libratherm Instruments delivers controllers for precise industrial operations

By OEM Update Editorial June 7, 2024 11:36 am IST

Libratherm Instruments offers industrial process control solutions. Their Thyristor Power Controllers and multi-zone heating systems provide precise industrial operations , as Vinit Panchal, CEO of Libratherm Instruments Private Limited, explains.

What is the latest range of products offered by Libratherm Instruments Private Limited?

Libratherm provides various solutions for industrial process control, including process sensing, indication, PID control, signal processing, and AC/DC power control.

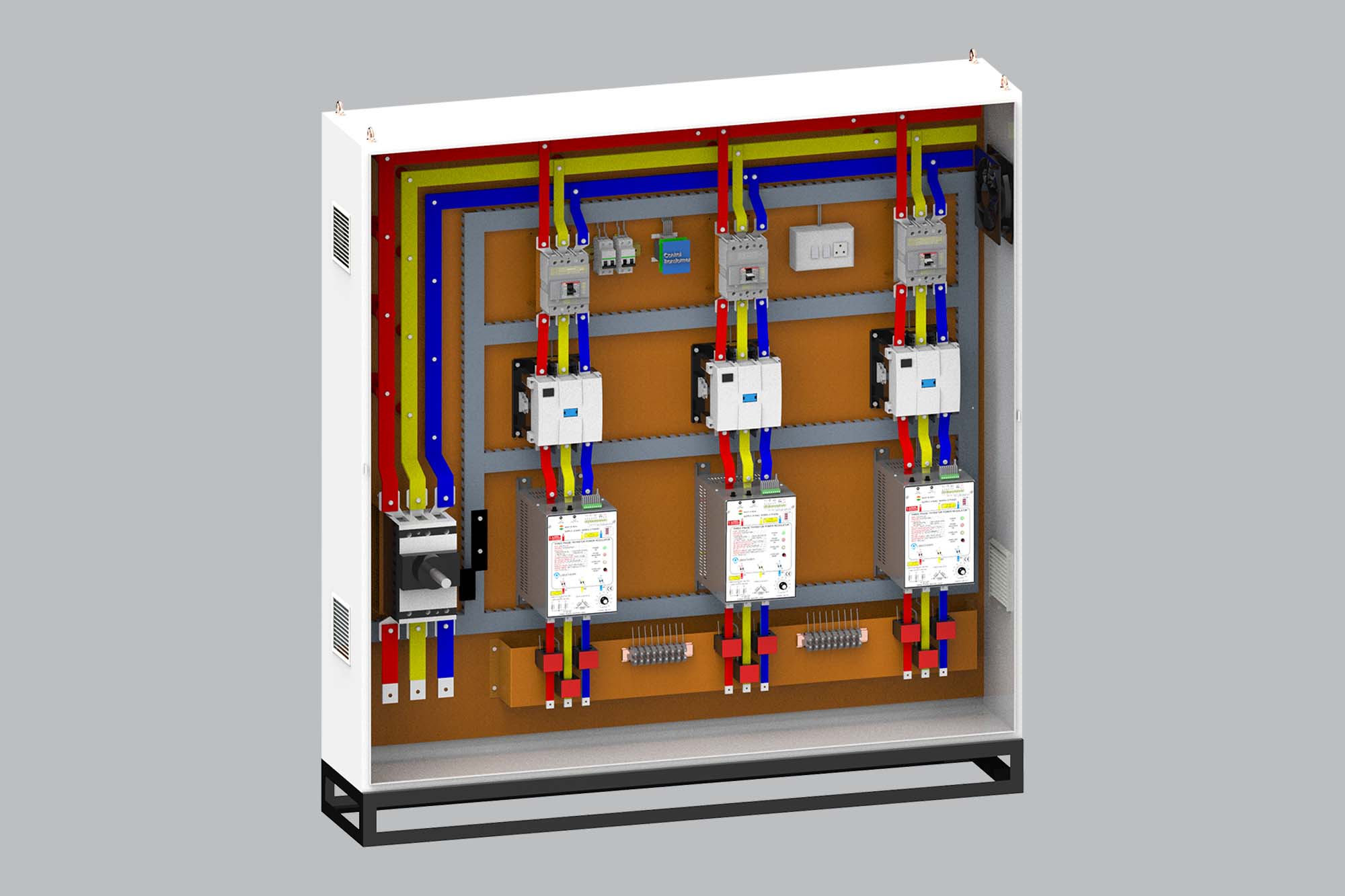

Our key product categories are Thyristor Power Controller/Switches, encompassing AC-AC power controllers and switches ranging from 10A to 500A. We provide PID Controllers in single and multi-zone configurations for precise temperature control. Libratherm also offers Temperature and Humidity Measuring Instruments, Signal converters, Signal isolators, Temperature and Process Data logging systems, Clean room monitoring systems, and Molten metal pyrometers. These solutions cater to various aspects of process sensing, indication, PID control, signal processing, and AC/DC power control for efficiency and accuracy in industrial operations.

Can you elaborate on the features of the multi-zone heating system for research laboratories?

Multi-Zone heating system creates uniformity of temperature. This technology divides laboratory apparatus into sections with heating elements and temperature sensors for precise control. Experiments conducted using temperature-sensitive materials in production and research applications are guaranteed to be exact and repeatable.

Multi-zone heating systems also help maintain a consistent temperature throughout large equipment. They compensate for uneven heat distribution due to complex internal geometries, making the temperature consistent regardless of the size or shape of the equipment.

A multi-zone heating system controls different heating elements independently. Each heating zone has a control system that connects to a central interface. It allows operators to set different target temperatures for each zone. This facilitates multiple experiments with unique temperature requirements running within the same equipment. You can also create complex heating profiles to support advanced material processing or experimental simulations.

The ramp soak cycle involves controlled heating, maintaining a temperature, and controlled cooling. Multi-zone systems allow customisation. Tailored Material Treatment provides fine-grained control over material properties since replicating real-world conditions is crucial in many simulations.

How does the Thyristor Power Controller regulate power delivery in the multi-zone heating system?

Thyristors deliver tailored heat distribution in advanced multi-zone heating systems. A dedicated thyristor controls each heating zone independently. It assures that specific areas receive the required heat. These thyristors receive direct commands from the control zone of a PID controller. The seamless integration of thyristors and PID controllers maintains accurate temperatures throughout the system. Thyristor technology facilitates high-speeding and precise controlling. With this technology, the system can react swiftly to changing temperature demands. The results are optimal control and energy efficiency.

Which control algorithm does the temperature and humidity controller use for precise temperature control?

Libratherm DTH-966-AHU employs a combination of control strategies for temperature and humidity regulation in AHU systems.

The primary temperature control is achieved through a PID algorithm. The output of this algorithm is a smoothly varying analogue signal. This signal directly controls the 3-way valve to regulate the flow of hot or cold water. PID control is excellent for achieving precise temperature setpoints. It tracks and minimises overshoot/undershoot.

The controller can use PWM DC pulse output to manage the relative humidity. It also controls the opening and closing of solenoid valves. This action can add or remove moisture through misting or other humidification systems. Additionally, a thyristor unit can regulate the amount of power going to heating elements used for evaporating moisture.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.