How MachineXT transforms machine health through clean oil

By Staff Report August 16, 2025 6:09 pm IST

Mobil’s MachineXT offers reliability with advanced oil filtration and dehydration for machines that can tackle hidden contamination threats that cripple industrial efficiency.

Industrial machinery is the backbone of manufacturing operations, and ensuring its longevity and efficiency is crucial. A silent and often overlooked threat—oil contamination—can significantly compromise machine performance. Left unchecked, it leads to costly breakdowns, unplanned downtime, and reduced operational efficiency.

The Hidden Dangers of Oil Contamination

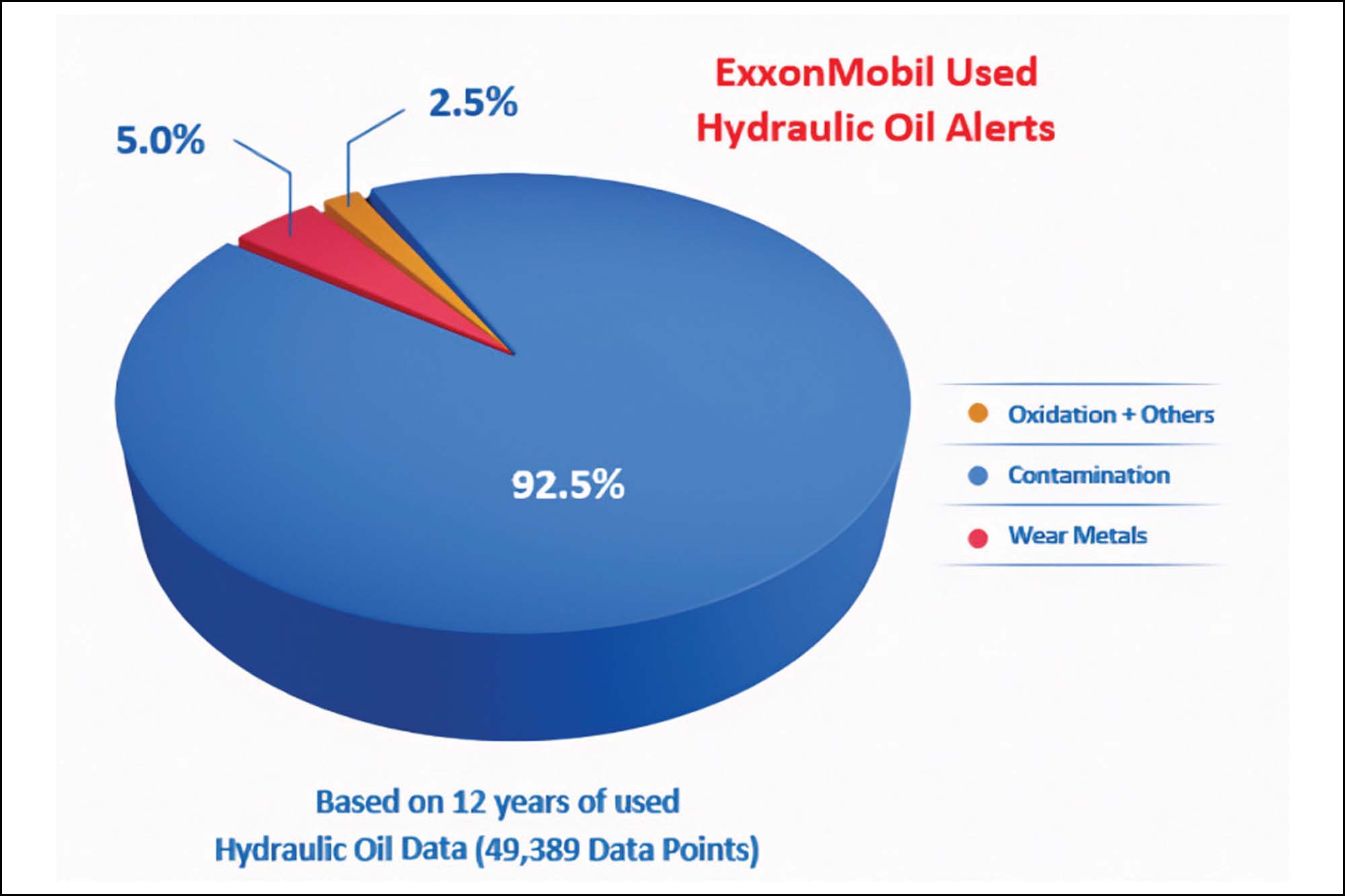

Oil contamination is a leading cause of machinery failure. Common contaminants—including dirt, dust, water, and depleted additives—can infiltrate lubrication systems, triggering pump and valve failures, reducing system efficiency, and driving up maintenance costs.

Contaminated oil also affects valve spools, causing erratic machine behaviour and reduced responsiveness. In hydraulic systems, contamination levels exceeding ISO 19/16/13(a) can drastically shorten equipment lifespan, triggering frequent repairs and escalating operational expenses.

Hydraulic systems operate with microscopic tolerances, often less than a micron. For instance, an anti-friction bearing has a clearance of just 0.5 microns(a) —meaning even the smallest particles can cause blockages, increase friction, and lead to catastrophic failures. The result: lower productivity, unexpected shutdowns, and higher total cost of ownership.

Water contamination is another hidden threat. Even trace amounts can cause rust, corrosion, and oil clouding, accelerating component wear. Research shows that increasing water content from 25 ppm to just 100 ppm can drastically reduce bearing life expectancy*, making moisture control essential for system longevity.

Preventing oil contamination

Maintaining clean oil is essential for ensuring smooth operations and extending the life of industrial machinery. Implementing proactive maintenance strategies can significantly reduce the risk of contamination and its costly consequences:

–Regular Oil Analysis

Routine oil testing helps detect contaminants early, allowing for timely corrective actions before damage occurs.

–High-Quality Filtration

Investing in oil filtration systems effectively removes harmful particles, extending both oil and equipment life.

–Seal Integrity Checks

Regular inspection and maintenance of seals prevent leaks and minimise the risk of external contaminants entering the system.

–Scheduled Maintenance

Timely servicing ensures potential issues are identified and addressed before they escalate into major failures.

Maintaining optimal oil quality through these measures ensures enhanced system reliability and reduced downtime.

MachineXT: An Enabler for Proactive Maintenance at Your Doorstep

Oil contamination is an unavoidable challenge in industrial operations, but proactive solutions can help mitigate its harmful effects. Mobil’s MachineXT is a cutting-edge service designed to combat this silent threat through advanced oil filtration and maintenance solutions. Whether it’s tackling particulate contamination, water intrusion, or fluid degradation, MachineXT helps ensure that hydraulic and other lubrication systems operate at peak performance with cleaner, longer-lasting oil.

MachineXT goes beyond traditional filtration. It features innovative dehydration technology that removes free and emulsified water—protecting systems from rust, corrosion, and additive breakdown. The result: improved oil performance, reduced unplanned downtime, and lower maintenance costs.

How MachineXT Delivers Superior Performance

- On-Site Oil Filtration

Delivers doorstep filtration services to remove contaminants, reducing the frequency of oil changes and extending oil life. - Tramp Oil Separation in CNCs

Extracts tramp oil to control bacterial growth and maintain the pH balance of metalworking fluids—enhancing sump life and fluid stability. - Metalworking Fluid Sump Cleaning

Removes chips, debris, and swarf from sumps, extending fluid life and minimising machine downtime.

By integrating MachineXT into their maintenance strategy, businesses can maintain cleaner hydraulic systems, boost shop floor efficiency, and realise significant cost savings.

The Takeaway: Cleaner Oil, Smarter Machines

Oil contamination is often underestimated—but its impact on machinery performance and operational costs is profound. With MachineXT, businesses can take a proactive approach to machine health, preventing breakdowns, enhancing productivity, and optimising long-term performance.

MachineXT isn’t just a filtration service—it’s a strategic investment in reliability, efficiency, and cost control. Because in industrial operations, clean oil isn’t a choice—it’s a necessity.

————————————————————————————————————

a)Disclaimer – Values mentioned in the documents are based on controlled tests and are representative. For precise data, please consult your equipment manual or OEM.

Reference: Machine design, How dirt and water affect bearing life by Timken bearing co.

(Exxon Mobil Corporation has numerous affiliates, many with names that include ExxonMobil, Exxon, Esso, and Mobil. For convenience and simplicity, those terms, and references to “corporation,” “company,” “ExxonMobil,” “EM,” and other similar terms are used for convenience and may refer to one or more specific affiliates or affiliate groups.)

For more information, visit www.mobil.in/business

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.