Metalworking fluids: Keeping the wheels of manufacturing spinning

By OEM Update Editorial July 8, 2020 5:45 pm IST

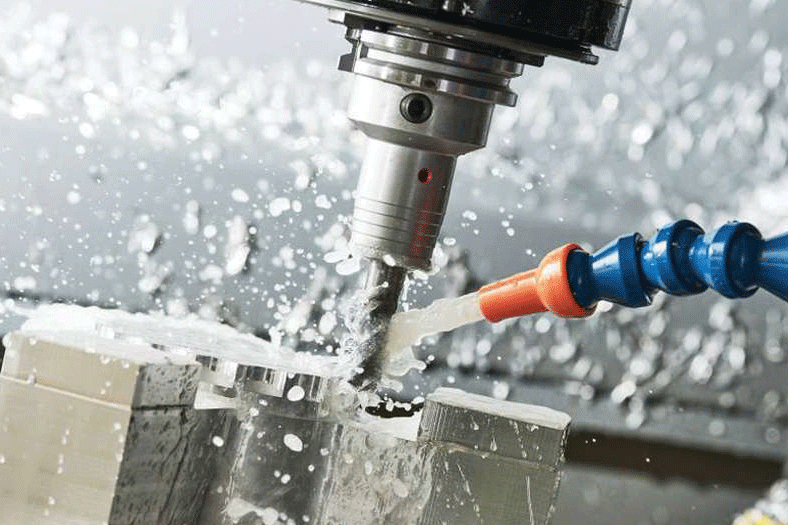

Machine tools keep the wheels of manufacturing turning. Metalworking fluids, also known as cutting fluids meanwhile, keep those wheels greased.

The Industrial Revolution changed the world. It was a time of breakthroughs and inventions that had a far-reaching technological, economic and even social impact that continues to be felt even today. It was an era rife with innovation. But one particular technological breakthrough could arguably be hailed as the most defining — the invention of machine tools.

Machine tools completely overhauled the manufacturing process, making it efficient, cheap, quick and most crucially lending it scale. It made large-scale manufacturing possible. Without it, our factories wouldn’t be churning out cars, components, computers and so on and so forth in the volumes that they do today.

The importance of machine tools to the modern manufacturing process cannot be understated. But there is one key ingredient that keeps them spinning — metalworking fluids. Machine tools keep the wheels of manufacturing turning. Metalworking fluids, also known as cutting fluids meanwhile, keep those wheels greased.

The process of cutting and grinding can be carried out without using a fluid. But because of its overwhelming benefits, the use of metalworking fluids has become commonplace, whether it’s in the cutting of coins or the manufacture of components used in an aircraft engine.

Not all cutting and grinding processes are the same. The severity of work can differ, as can the metals being worked on, the quality of water, and the age and amount of wear the tools have already. As a result, manufacturers typically tend to market a range of varied metalworking fluids suited to different needs. These can primarily be classified into four types.

Straight oil fluids, as the name suggests, are over 90 percent composed of oil. Soluble oil fluids have high oil content but are typically dissolved in water. Semi-synthetics have a low to moderate oil content but are mixed with water and performance additives. Lastly, synthetics are composed of water and water-soluble additives but no oil.

Each has their benefits and downsides. Some are great for lubrication but not so good when it comes to cooling. Others have excellent lubricity and heat reduction qualities but may be adversely affected by hard water.

Soluble oils such as the IPOL-branded Aquacut 125 are most widely used across industrial applications by some of the country’s blue-chip manufacturers. Soluble oils are known to have several benefits. To begin with, they have excellent lubricity and emulsion life. They offer a significant degree of heat reduction, are easy to handle, offer good resistance against corrosion, are versatile and above all economical.

Of course, given that manufacturing as we know it now is 200 years old, it has evolved a lot — as have metalworking fluids to keep in step with evolving industry practices. The metalworking fluids today are growing ever more cutting-edge, pardon the pun. They are allowing even greater precision and at the same time are more resistant to bacterial contamination.

This trend is only set to accelerate. As the technology that goes into developing metalworking fluids evolves, the lines between the different varieties available today and their pros and cons will continue to blur. They will continue to get more efficient, economical and sustainable. But most importantly, they will become an ever more indispensable part of the manufacturing process.

Authored by:

Dr. Kalpendra Rajurkar, Head of Technology, GP Petroleums

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.