AceMicromatic eyes $1 billion by 2029

By Staff Report June 5, 2025 4:35 pm IST

AceMicromatic Group is a contending example of local technologies having a global effect. Raguramachandran. C. R., CEO of AceMicromatic International, shares insights on export growth, international market strategy, product adaptation, and how AMI is building a strong global support ecosystem to serve OEMs worldwide.

With growing interest in ‘China+1’ strategies, what opportunities has ACE seen to become a preferred machine tool partner for global OEMs in India?

AceMicromatic Group is one of the pivots in the Indian manufacturing sector, contributing a little over 30% of the country’s CNC machine requirements. Our progressively engineered products have always enabled our customers to achieve the best productivity at a lower cost per component. The geopolitical situation presents opportunities and challenges, especially on the China+1 front.

We, as an Indian brand, have been operating in China for over 17 years, with our CNC machines deployed across 60 different cities and sectors within that country. Our presence there has provided insights into the requirements of any global OEM or manufacturer set up in India. Our support for any new global OEM starts from selecting the correct machine specification and providing single machine tooled-up or complete integrated solutions, including gantry/ robots, commissioning, post-warranty support, and AMC’s.

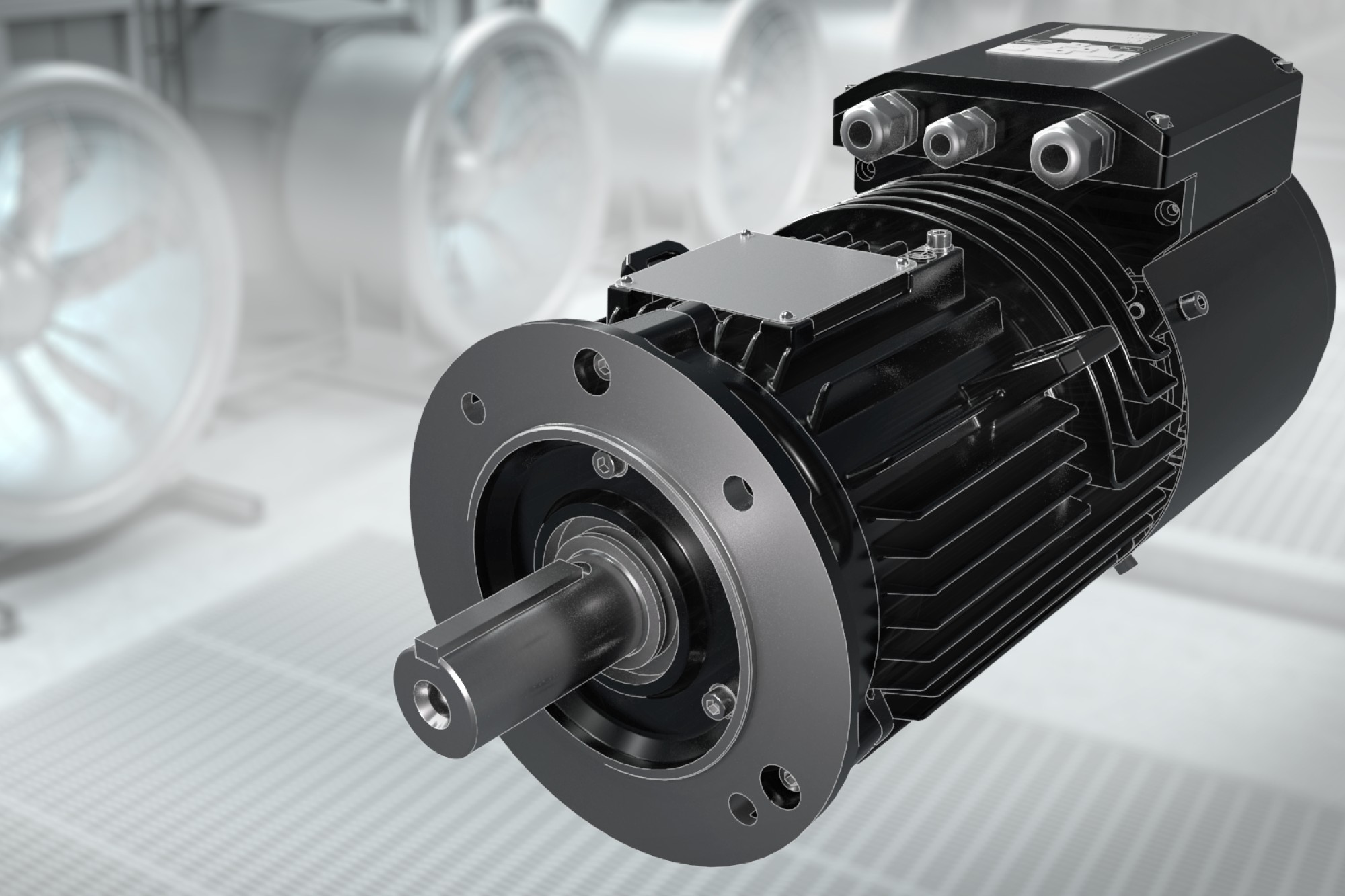

As the most preferred machine tool supplier, having supplied over 100,000 machines in the market, we have a complete range of products to ease and aid customers in setting up a machine shop from the ground up. These include CNC lathes, machining centres, and grinding machines, along with eco products like coolant, lubricant tooling, measuring instruments, etc. This provides customers with a single advantage from us.

As a progressive technology company, we are always for our customers’ requirements. We have also enhanced specifications and features in our present product range. We have a strong product line to address growing EMS needs. More emphasis is placed on the reliability and performance of the present machine, along with product launches of multi-axis, multi-spindle and higher speeds and feeds on the machines.

With our direct presence of sales and service teams in over 70+ locations in India, any OEM, global player, or start-up has a unique advantage of productive, reliable products and a dependable support system for scaling their business.

In terms of exports, which international markets are becoming more prominent for ACE, and what strategies are in place to deepen your global footprint?

AceMicromatic is aiming to reach $1 billion in revenue by 2029. We’re working towards getting 25% of that from exports, focusing on key international markets like China, Southeast Asia, the Middle East & North Africa (MENA), and Mexico. Even today, our exports contribute a strong single-digit percentage to our revenue, and we’re putting significant investment, focus, and energy into scaling this rapidly. We have already set up our WoS in Germany and China and joint ventures in Mexico and Dubai. We are in the process of finalising a facility to reach customers in Southeast Asia.

Our strategy to reach customers is adopting the hub-and-spokes model. Our offices act as hubs, with all the core facilities, and our distributors act as spokes for reaching out to end users. Being closer to the customer, at these facilities we stock full range of our machines and spare parts, and we have a factory-trained team of engineers to support customers in the pre-and post-sales process.

Our local presence helps us understand customer requirements and allows customers to experience the machine and its performance through component trials at these tech centres. This arrangement helps us further deepen our market presence.

What challenges does ACE face when adapting products for export markets, where infrastructure, standards, and user expectations may differ significantly from India’s?

While no significant difference exists between machines designed for export markets and those for the Indian market, each region must address specific safety standards. For instance, there is the CE mark for Europe, the CCC certificate for China, and the UL standard for the USA. Additionally, electrical standards vary between these regions. We encounter challenges regarding the interchangeability of our sub-assemblies, particularly with the CNC system, as the CE marking requires a different packaging approach.

The Asian market requires 2/3-axis machines with low-cost appropriate automation, specifically in Thailand, Vietnam, and Indonesia. We are looking at stocking these machines, which are ready for delivery. China is the largest consumer of machine tools and a demanding market. With our strong network of local partners, we provide total solutions with gantries and robots. We cater to different industrial segments.

In Middle East Asia, the product and industrial segments are different. They mainly cater to large components for oil and gas, die mould segments, and general engineering, so machine specifications and features need to be addressed accordingly.

Can you explain how ACE develops global service, training, and support ecosystems to enhance its brand outside of India, particularly in areas with a shortage of skilled machinists?

AceMicromatic has strong expertise in customer service and support. In India, nearly 80% of our service calls are attended to within 4 hours, per our CRM data. Matching this level of service globally is a big challenge, but one we’re actively working on. Notwithstanding the geographical distance and time zone difference, we utilise technological tools to diagnose and handhold our distributors online to provide quick resolution. Apart from that, we have enabled the IoT platform in the machines to provide the customer with the necessary information for self-diagnostics tool kits. Another important differentiator is that we speak the language where we operate, which means our manuals and local service engineers talk and interact with the customers, making our presence local while being global.

We ensure that all our dealers/distributors are factory-trained. They must undergo yearly training at our world-class facilities in Bangalore. This ensures that all our customers get the same experience with our global service. Our tech center also serves as the training center for our customers.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.