Chatting with smart machines

By Staff Report August 28, 2025 12:38 pm IST

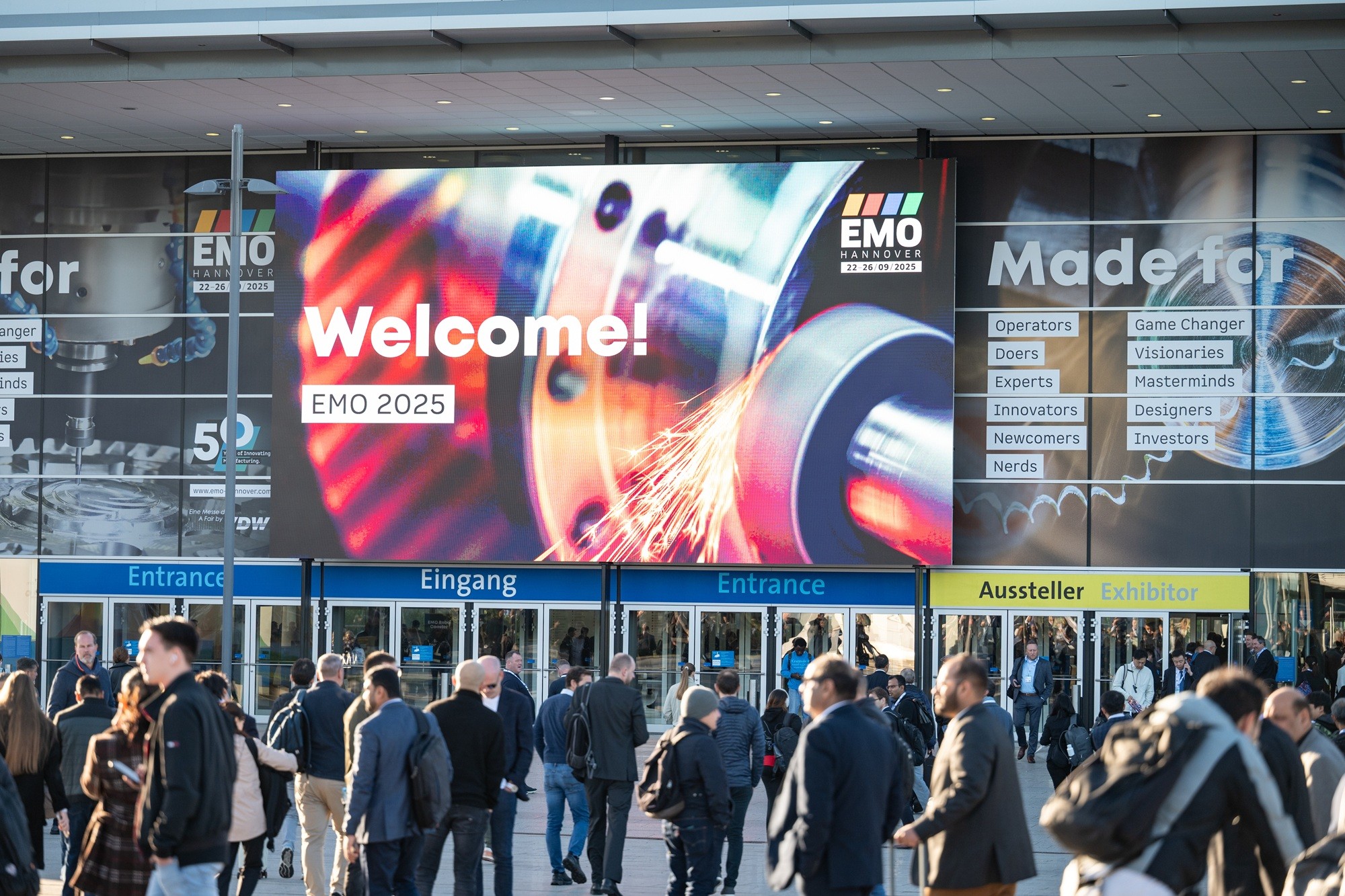

At EMO Hannover 2025, industry leaders highlight how automation, AI, and digital training reshape manufacturing by enhancing efficiency while keeping humans indispensable through smarter assistance, reskilling, and future-ready workplace solutions.

Automated and networked machines, digitalised process chains and autonomous transport systems: The industry trends at the EMO Hannover 2025 almost give the impression that humans are no longer needed in production facilities. However, experts from science and industry disagree with this idea. They explain that it is, in fact, true that technology does allow production activities to operate with fewer employees, which is vital in view of the current shortages of skilled workers. However, humans remain indispensable when it comes to maintaining an overview of complex situations and being able to intervene in them as necessary. Assistance systems and, more recently, artificial intelligence are helping to make this as easy and safe as possible. And this is a development that could increase the attractiveness of jobs in production.

The shortage of skilled workers is currently affecting the operations of many companies worldwide. According to surveys by the Munich-based ifo Institute, almost one in three companies in Germany alone complain that they cannot find enough skilled workers. The reasons for this are complex and cannot be attributed solely to demographic change. “It’s often not just a lack of personnel, but also a lack of efficiency,” says Michael Daniel, CEO of Datron AG from Ober-Ramstadt/Hesse (Germany), and he further emphasises: “As a machine manufacturer, we see it as our responsibility to offer solutions in precisely this area.” According to Mr. Daniel, modern machines, automation and digital assistance systems make it possible to achieve more with fewer staff – while at the same time improving quality and reducing the workload on employees.

Step by step through the process

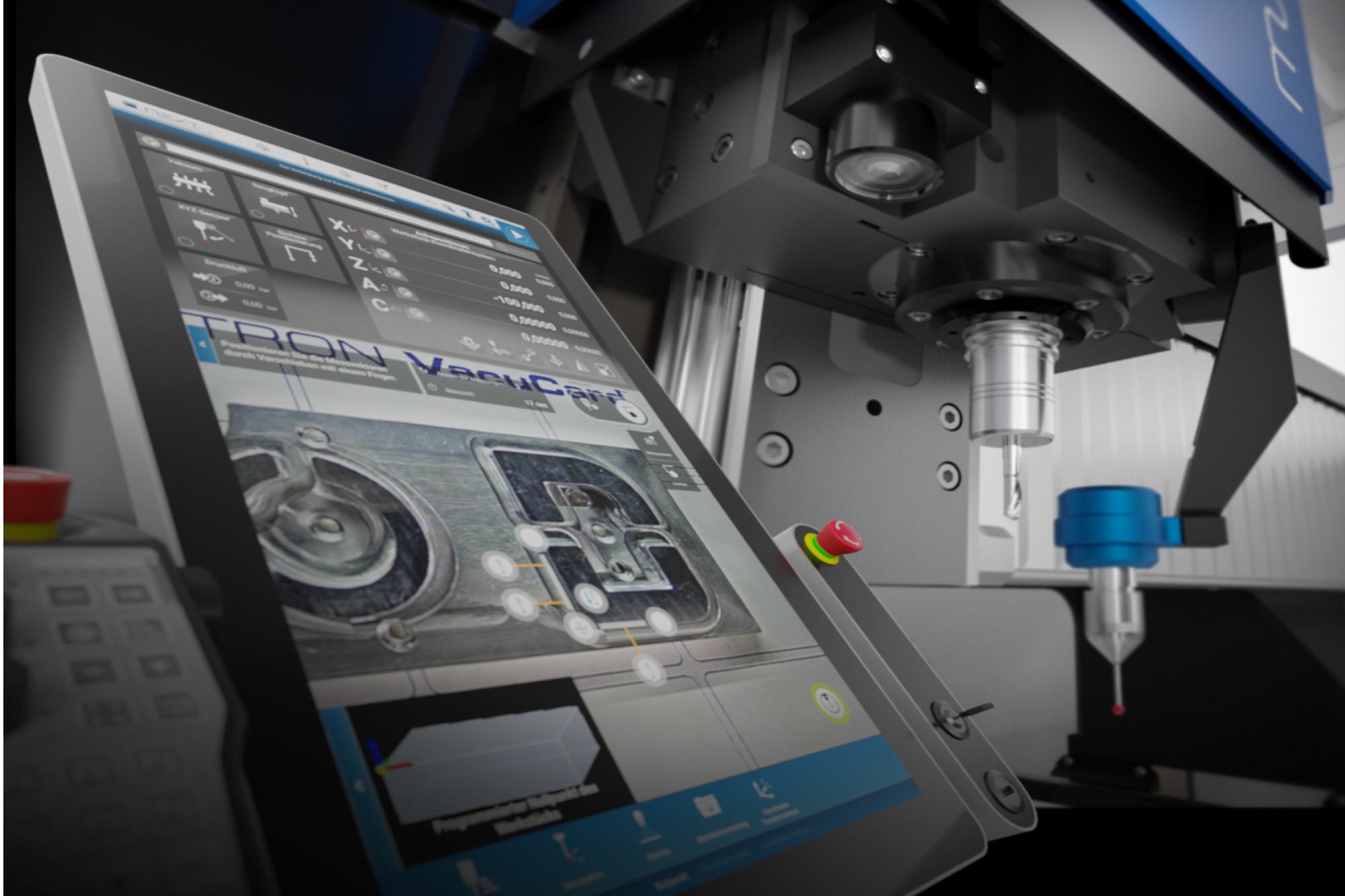

At Datron, this primarily means that machines are becoming ever smarter, thanks to adaptive control systems, integrated sensor technology and intuitive user interfaces. This means that even less experienced operators can achieve highly accurate results. At the same time, the company sees a strong future for assistance functions that guide users step by step through processes, help to prevent mistakes and reduce training costs. According to the CEO of Datron, another focus of the company is on the digitalisation of workflows. From CAM programming through to machine feedback, this approach produces a continuous flow of data that creates transparency and identifies areas of potential for optimisation – for example, in terms of set-up times, energy consumption or maintenance cycles. “We believe in technology that isn’t simply there for the sake of it, but instead is geared towards the user to really make their jobs easier and improve efficiency,” says Michael Daniel.

Dr. Elisa Roth, CEO of Munich-based Augmented Industries, also has a strong interest in the technical possibilities for assisting production workers as effectively as possible. She completed her doctorate at the Institute for Manufacturing of the University of Cambridge on the topic of technology-supported learning and worker assistance systems. The range of solutions she looked at extended from exoskeletons (assistance systems worn on the body) and smart eyeglasses through to virtual and augmented reality. Dr. Roth came to the conclusion that, although the technology has fascinating potential, much of it has proven to be very complex and sometimes technically unstable or uneconomical. “It doesn’t always fit in to a production setting,” she says. “Here, there is a need for stability, quick wins and minimal update requirements, while at the same time giving employees as much freedom to operate as possible”.

Training AI for individual assistance in the workplace

As co-founder of Augmented Industries, a key area of focus for Dr. Roth is on the use of artificial intelligence for an individual worker assistance system that can be used directly in production and service alongside the worker’s day-to-day activities. Depending on the operational requirements, it can be used on many different types of devices, whether it be a touchscreen, PC, smartphone or tablet. The AI is supplied with information that is relevant to both the company and the particular processes involved. It can create digital step-by-step instructions and answer questions, which in turn helps to break down workers’ inhibitions. “We found that many employees find it easier to ask the AI questions, rather than admit that they don’t know certain things to their supervisors or fellow workers,” explains Dr. Roth.

She also believes that the trend in training and further education is clearly moving towards digital solutions, because companies can increasingly ill afford to have employees absent for training purposes. There is also a lack of good trainers, so there is no other option than to provide support digitally. However, off-the-shelf training material is of little use in production settings where around 70 percent of the required knowledge is specific to the products and processes involved. The advantage of AI for training is that all of the information comes only from the company itself and can then be prepared for training purposes. For example, the AI can turn a 100-page work instruction document into numerous smaller “knowledge nuggets”, each taking no more than three to five minutes to complete and therefore easy for the worker to retain. Content can be prepared as step-by-step instructions, quizzes, multiple-choice questions or interactive swipe tasks, which can be easily set up by the respective production or service manager without external help. An additional advantage for qualification management is that the system records who has already completed which training courses, assigns worker-specific content and can provide information on who is qualified and can be assigned to a job or service task accordingly. This automated qualification matrix saves forepersons and team leaders the need to carry out additional data entry work as part of ISO9001 audits.

Augmented Industries spent more than two years developing its human-centric AI agents, explains Dr. Roth, while taking all safety mechanisms and relevant compliance rules into account. Customers now include companies such as Siemens, BMW and ZF, and ambitious targets have been put in place: “By 2030,” says Dr. Roth, “we want to train around one million skilled workers.” Another of the company’s reasons for attending the EMO 2025 is to find out about trends in production technology and thus gain further insights into possible training topics.

Training topics are part of the DNA of the EMO

Training and educational topics have always been an integral part of the EMO, which features a special education showcase, helping the trade fair to establish itself as one of the most important platforms for promoting young talent in mechanical and plant engineering. The special showcase is a joint initiative of the Nachwuchsstiftung Maschinenbau foundation for training in mechanical engineering and leading technology companies from the metalworking sector. Industry viewpoints and talks will focus on trending topics such as future skills, artificial intelligence in training and new learning environments for vocational training.

Great efforts are being made to get young people, in particular, interested in production technology. Prof. Jutta Rump, Director of the IBE (Institute for Employment and Employability) at the Ludwigshafen University of Business and Society, recently emphasised that an equally great effort should be made to keep skilled workers in production for as long as possible and enable them to adapt to a rapidly changing world of work. In the Tech Affair podcast of the VDW (German Machine Tool Builders’ Association), she calculated that around 13 million skilled workers in Germany will retire from the labour market by 2030, but only 6.5 million new staff will come up through the ranks to replace them. She believes that not only do companies need to invest much more in their productivity than before. There is also an urgent need for professional HR management aimed at proactively training employees. She explains that, especially in times of structural change, with job cuts in some areas going hand in hand with shortages of skilled workers in others, reskilling is important to open up new prospects for workers in areas where there is a need. It could basically be seen as negligent if we fail to focus more on the needs of certain groups, such as older workers, skilled foreign workers whose language skills may not be up to scratch or women with children that they cannot find suitable childcare for. When it comes to acquiring staff, the ability to offer suitable jobs and individual support is are key factor, explains Prof. Rump.

Datron CEO Michael Daniel shares a similar view, emphasising how important it is to promote further training with individual development paths that are geared towards people’s strengths and interests. Employees appreciate the freedom to be able to work independently, whether in production, service or development. Mr. Daniel is convinced of this fact: “What makes us attractive is a culture that recognises performance, respects the work-life balance and allows for development.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.