New Seco Face Milling Cutter offers high flexibility and ease of use

By Staff Report February 19, 2025 7:34 pm IST

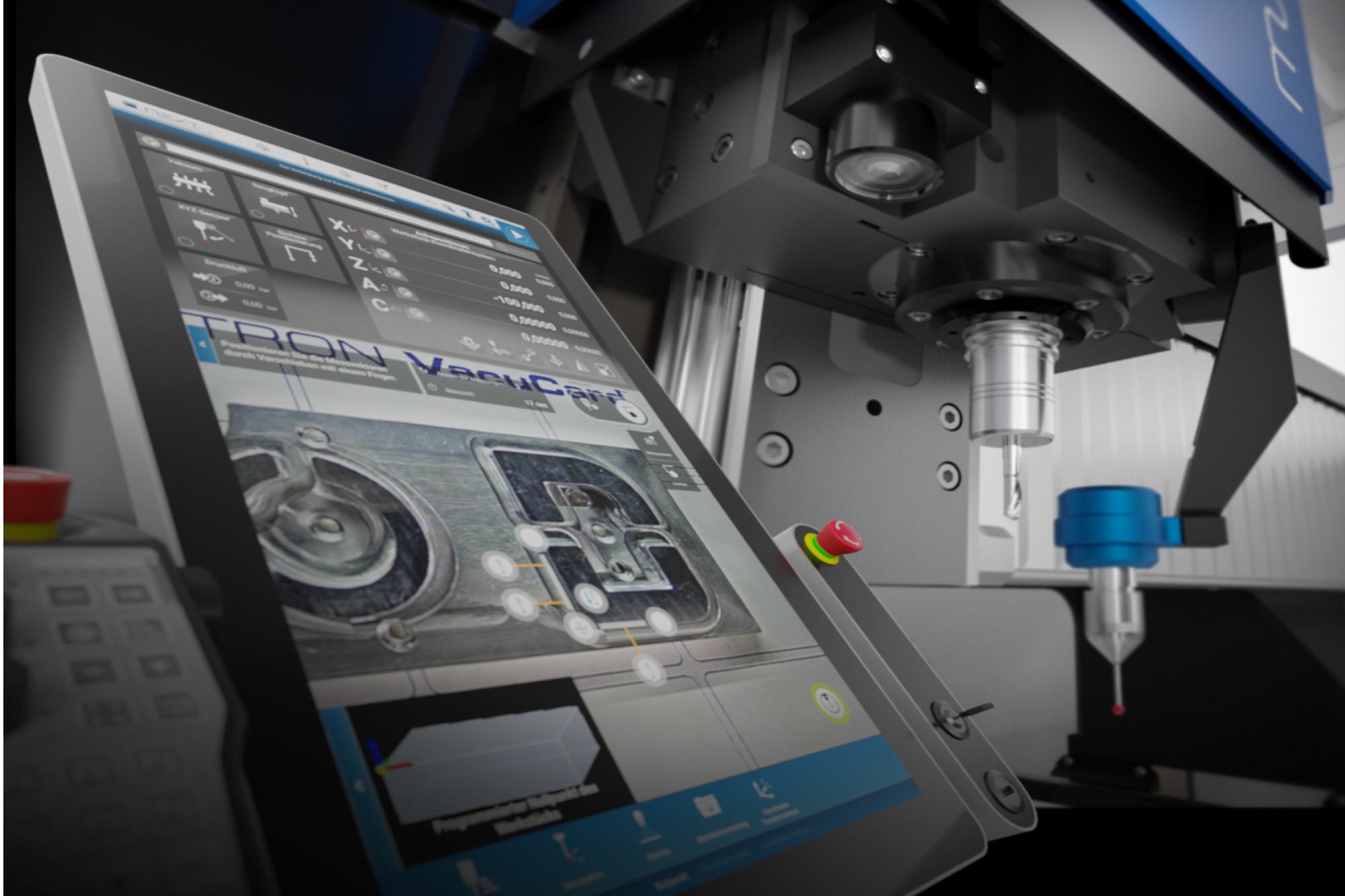

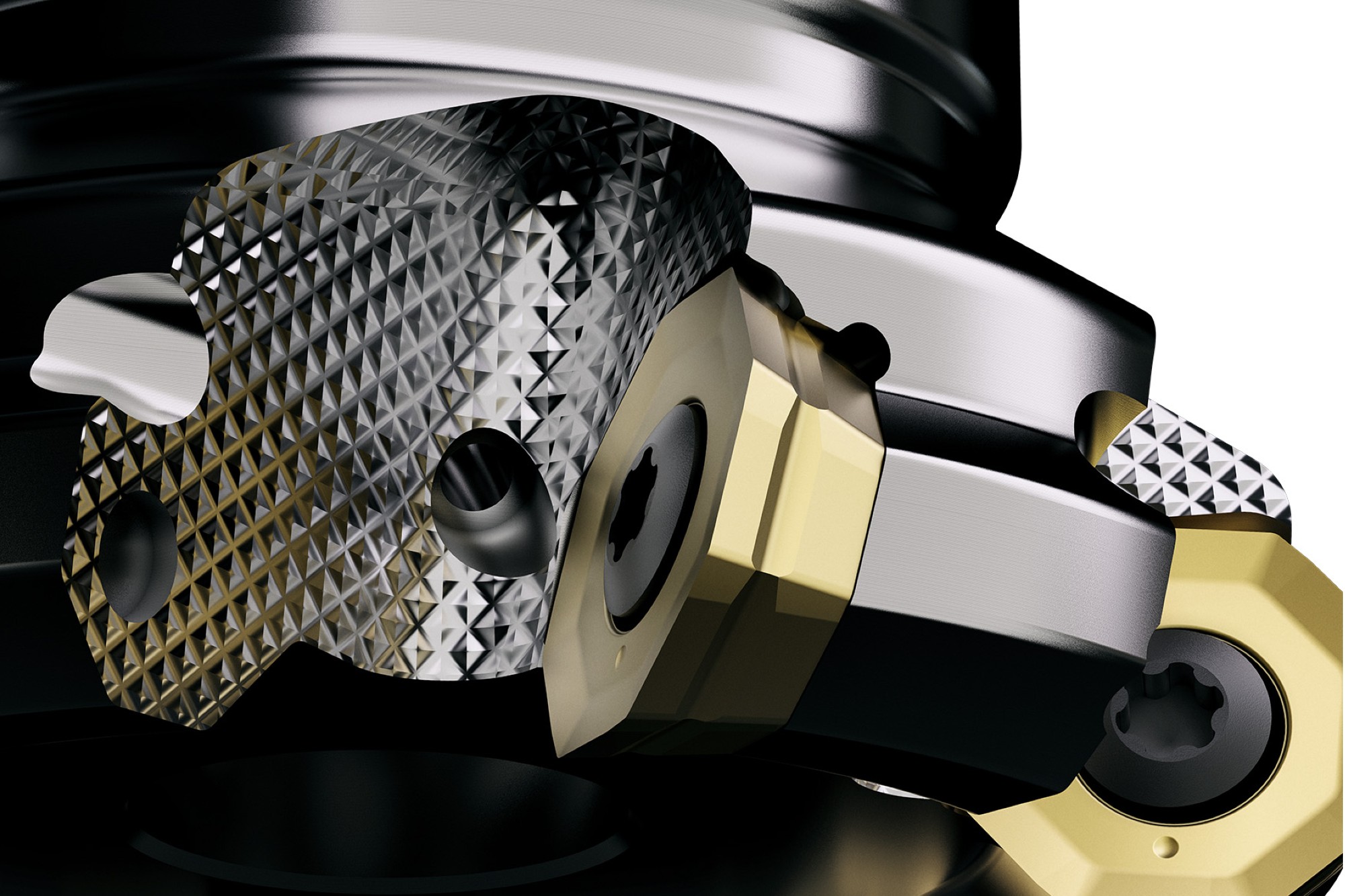

The new generation of the Seco Octomill 06 Face Milling Cutter provides significant improvements to ease-of-use, flexibility and stability. The cutter ensures self-centring of inserts for reliable, error-free positioning and incorporates a multi-insert pocket design that accommodates a variety of insert types for a range of applications.

Easy to use and reliable

Octomill 06 self-centering inserts allow operators to quickly and securely position inserts with high repeatability. The use of a long insert screw enables indexing of an insert without having to remove the screw from the cutter body. The cutter-insert interface design disconnects cutting edges from support surfaces and mimics the design of a double-sided insert while keeping the positive setting approach of a single-sided solution.

New generation Seco Octomill 06 Face Milling Cutter 1

“This separation of cutting edges and support surfaces keeps worn portions of the insert from damaging or negatively impacting the performance of unused edges,” said Seco Product Manager Tobias Jakobi. “Furthermore, the self-centering feature prevents the occurrence of incorrectly positioned inserts that can cause instability, edge and tool breakage, costly work interruptions and the need for rework.”

The Octomill 06 is a top choice for applications featuring unstable setups or thin-walled parts. Featuring a right-handed design with a straight cutting edge, Octomill 06 incorporates a high helix angle of +16° to reduce radial and axial forces and enable high-quality production. The cutter achieves smoother entry and exit and reduces back cutting effects. Additionally, Octomill 06 provides consistent wear along the entire cutting edge.

New generation Seco Octomill 06 Face Milling Cutter 3

Flexibility across a wide range of applications

The multi-insert pocket design of Octomill 06 accommodates face milling, round and moderate high feed inserts. This allows a single cutter body to effectively perform a variety of applications, including face milling, ramping, helical interpolation and profiling. A diverse range of insert grades and geometries provides optimal performance in materials spanning the P, M, K, N, S and H Seco Materials Groups.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.