Objectify rethinks prototyping with localised additive manufacturing

By Staff Report June 30, 2025 6:17 pm IST

Founded in 2013 at SIIC, IIT Kanpur, with a small desktop 3D printing machine, Objectify Technologies has since grown into one of India’s leading players in the additive manufacturing and 3D printing industry. Ankit Sahu of Objectify Technologies Pvt. Ltd. shares insights into the company’s journey, the comprehensive solutions it offers, and how its expertise in both polymer and metal 3D printing keeps it ahead as a trusted additive manufacturing service provider in India.

With the growing demand for localised supply chains, how is your company addressing the need for faster, agile prototyping within India?

Objectify Technologies supports India’s shift toward localised supply chains through fully in-house additive manufacturing solutions. Our rapid prototyping services, spanning design for AM, metal and polymer 3D printing, and post-processing, enable faster iterations and product validation without reliance on overseas tooling or imports.

How are you using digital twin technology or simulation to reduce prototyping time and improve accuracy?

We contribute to digital twin workflows by ensuring manufacturability through AM-focused design support, print process simulation, and validation through iterative physical builds. While we do not conduct full-scale virtual simulations, our proactive engineering input ensures reduced development cycles and improved part performance from the first build.

What changes have you made in your prototyping process to support the EV and energy storage components market?

We’ve tailored our AM services for the needs of the EV and energy storage industry by offering materials like aluminium alloys and high-strength polymers. Our team focuses on optimising part geometries for lightweight, thermal performance, and space constraints. This delivers functional prototypes that accelerate testing and integration for EV systems.

How is your company integrating AI or machine learning into design validation or testing during the prototyping phase?

We are exploring the potential of AI and ML for building failure prediction, design automation, and quality assurance. Our goal is to gradually incorporate AI capabilities that align with additive manufacturing and bring measurable value to our design and production processes.

In light of global raw material volatility, how are you ensuring material efficiency and cost-effectiveness in component production?

Additive manufacturing naturally reduces material waste, and we maximise efficiency through optimised part design, careful nesting, and powder recycling practices where applicable. We also prioritise sourcing materials locally to avoid cost fluctuations and maintain supply stability.

With rising demand for shorter product development cycles, how are you enhancing speed-to-market for your customers?

By providing all prototyping services under one roof, from design consultation to final part delivery, we reduce the friction and delays typically seen in traditional development. Our AM-driven workflows are ideal for quick design iterations, low-volume functional parts, and bridging the gap to mass production with minimal downtime.

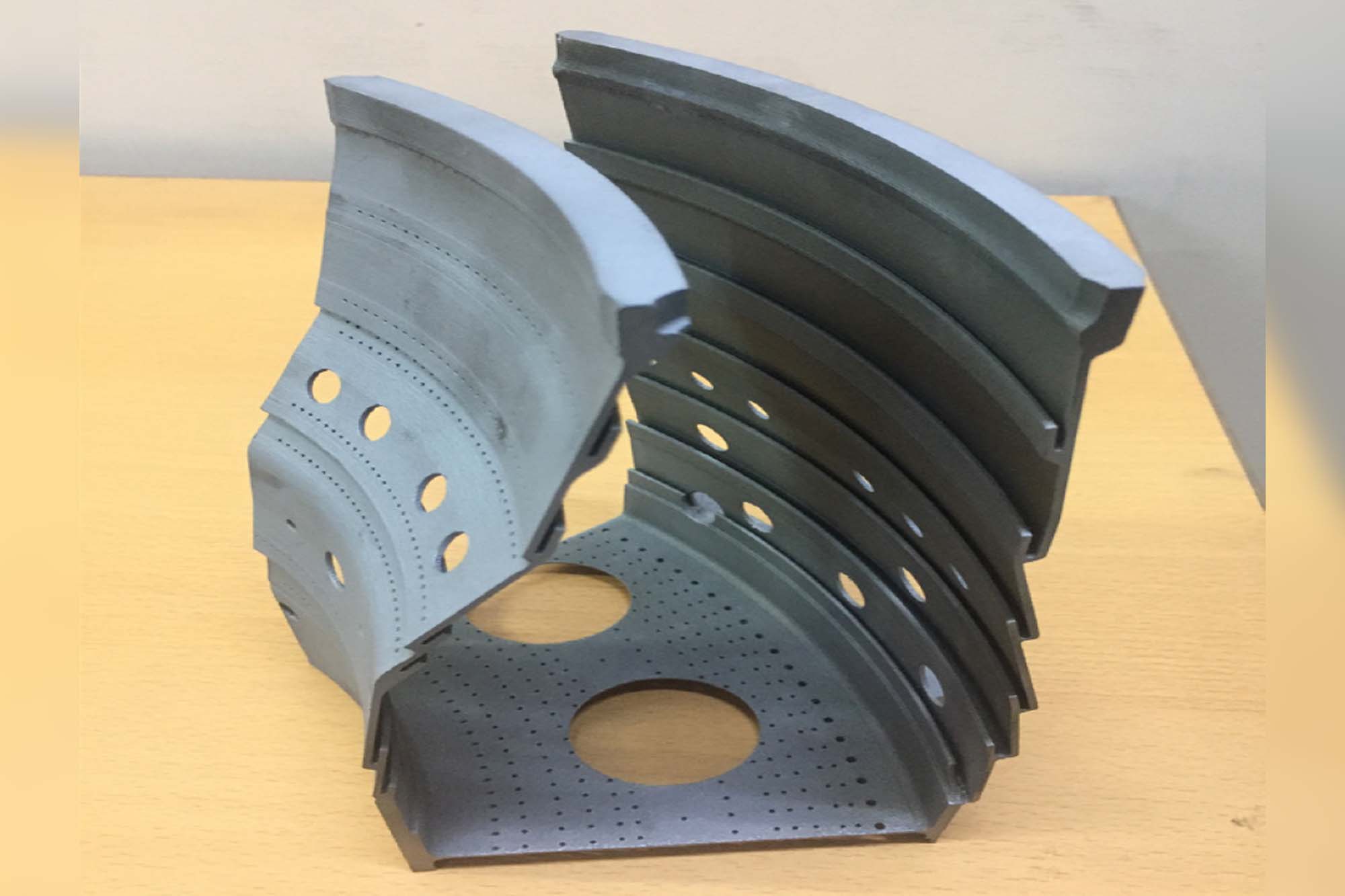

Could you share a recent success story where your prototyping capabilities helped an OEM overcome a critical design or supply challenge?

We recently partnered with an EV component OEM experiencing extended tooling delays. Our team helped re-engineer the component for AM, validated printability through test builds, and delivered production-grade aluminium prototypes within 4 days, helping the OEM maintain its internal timelines and avoid delays in product rollout.

How are you future-proofing your prototyping and component manufacturing services in the face of evolving global standards and digital manufacturing trends?

Objectify is investing in expanding our AM infrastructure, adding new materials and machine capabilities, and aligning with global standards such as AS9100D. We’re also exploring automation, AI tools, and digital traceability systems to stay competitive in the evolving landscape of digital manufacturing and Industry 4.0.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.