Swiss Steel introduces new alloys for spring wire applications

By Staff Report May 24, 2025 12:55 pm IST

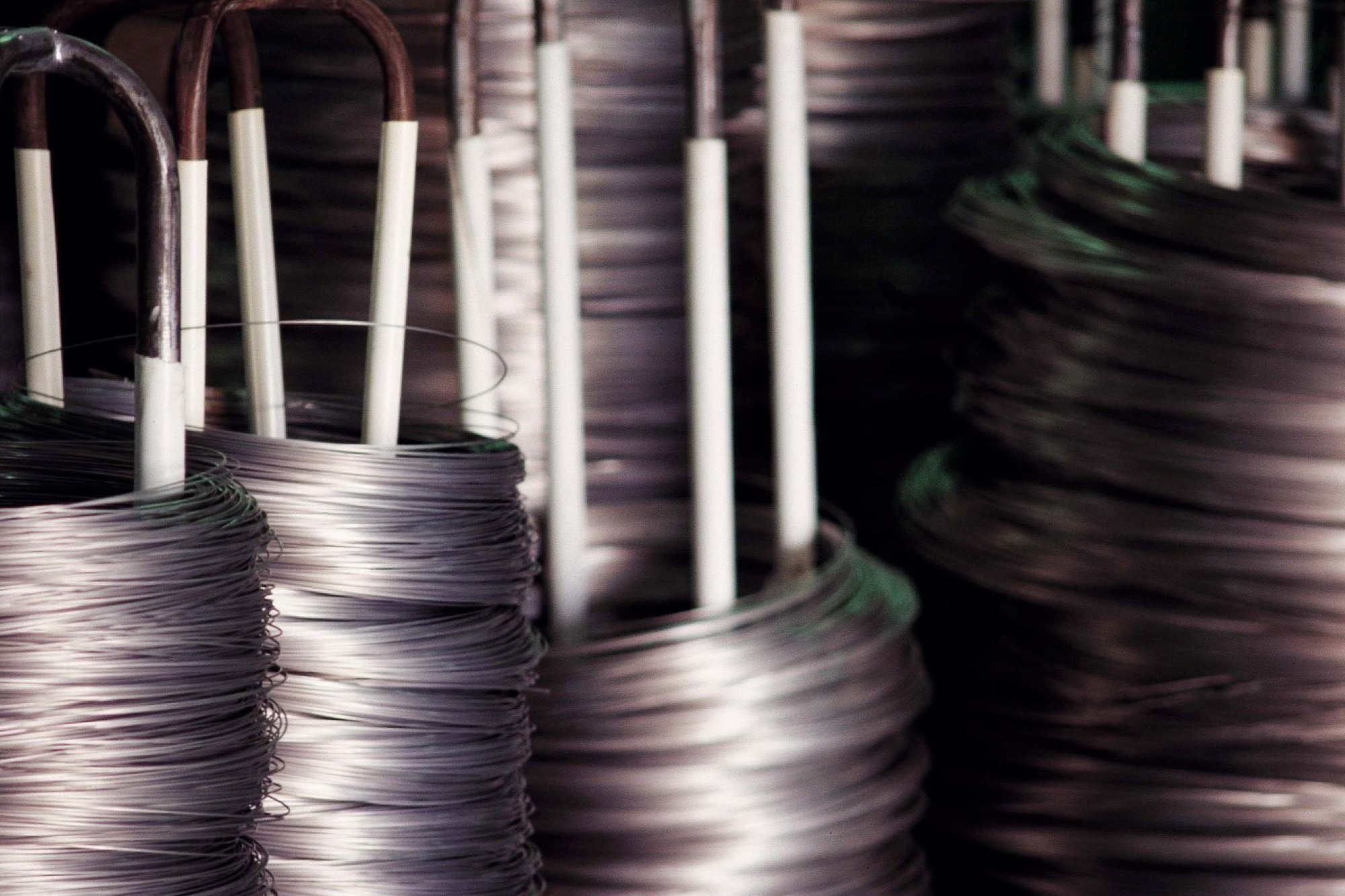

Swiss Steel Group advances production of cold-drawn wire for spring applications through a fully integrated process.

Swiss Steel Group, an international manufacturer of steel, continues to strengthen its position in the production of cold-drawn wires for spring applications. The company meets the technical demands of sectors such as aerospace, medical technology, pump systems, automotive engineering, and power generation through an integrated manufacturing process from steel melting to the finished wire.

Requirements for Spring Wire Characteristics

The market for stainless spring wire is evolving, driven by the need for mechanical performance, tolerances, and resistance to corrosion and hydrogen. In forming operations, material solutions are required to exhibit purity, surface quality, and reliability. Swiss Steel Group addresses these through process optimisation and R&D at its Ugitech subsidiary, based in Ugine, France.

Applied Research: Surface Quality and Material Behaviour

The research centre of the Stainless Division in Ugine works with the customer technical support team to develop application-specific solutions.

Key areas of focus include:

- Optimisation of surface finish in drawn wires to minimise crack initiation under loading conditions.

- Hydrogen behaviour analysis of cold-worked grades such as UGI® 202N and UGI® 209 to mitigate embrittlement risks.

- Implement testing procedures throughout the upstream and downstream production stages to ensure application compliance, including pump springs and solenoid valve components.

Vertical Integration as a Quality Driver

Swiss Steel Group applies vertical integration, from steel production in Ugine to wire drawing in plants in Imphy (France) and San Vendemiano (Italy). This enables:

- Control of metallurgical parameters.

- Monitoring of surface integrity across all stages.

- Each production lot is traceable.

Alloy Innovations for Applications

Swiss Steel Group has developed alloys to meet requirements for strength, resistance, and durability:

- UGIPURE® 4568 and UGIPURE® 4462: remelted round and shaped wires offering inclusion cleanliness for fatigue life.

- UGIS® 4462 (Duplex): engineered to comply with ISO 6931-1 for spring steels, providing a balance of performance, resistance, and efficiency.

- Wire diameters from 0.18 mm to 20 mm, available in round and profiled configurations for industrial uses.

Sustainable Manufacturing: Green Steel as Standard

All spring wire products are produced under Swiss Steel Group’s Green Steel standards. This ensures reduced CO₂ emissions while maintaining technical performance and product integrity.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.