The role of smart machining in India’s aerospace manufacturing growth

By Staff Report May 30, 2025 11:58 am IST

Sandvik Coromant and OEMs enhance quality and efficiency in India’s aerospace industry.

How advanced machining technologies are supporting India’s aerospace manufacturing and supply chain growth

Aerospace scientist and former President of India, Dr A.P.J. Abdul Kalam, stated, “Dreams transform into thoughts, and thoughts result in action.” This reflects the direction of India’s aerospace sector, which is projected to become the third-largest aviation market by December 2025.

To maintain this momentum, improvements in component production and supply chain efficiency are essential. Sunil Joshi, President – Sales, India, at Sandvik Coromant, discusses the role of advanced machining technologies in supporting the country’s aerospace goals.

Industry Development and Manufacturing Trends

India’s aerospace industry shifted from import reliance to increased domestic capability, supported by policies like Make in India and the Production Linked Incentive (PLI) scheme. These initiatives boosted domestic manufacturing, attracted foreign direct investment, and promoted workforce training.

India’s Maintenance, Repair, and Overhaul (MRO) sector is now among the fastest-growing in the Asia-Pacific region. Global OEMs, including Boeing, Airbus, and Rolls-Royce, are increasingly sourcing critical components from Indian suppliers. States like Tamil Nadu, Karnataka, and Maharashtra are emerging as regional aerospace hubs.

Adoption of Advanced Materials and Machining

To meet industry requirements, manufacturers are increasingly using materials such as titanium and heat-resistant superalloys (HRSAs). These materials reduce component weight and improve fuel efficiency, but they pose machining challenges due to their hardness and heat resistance.

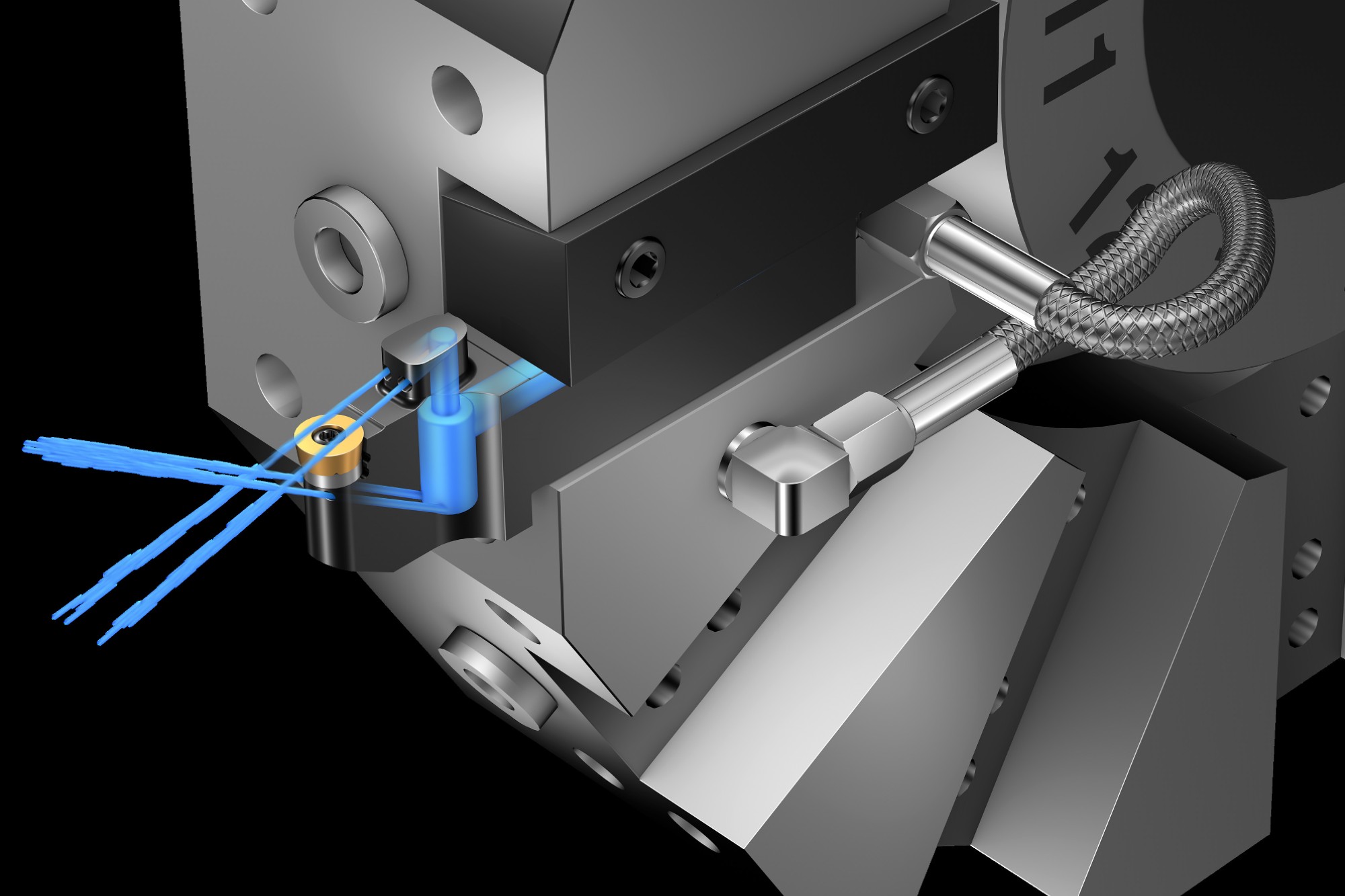

Advanced machining tools are crucial in addressing these issues. Sandvik Coromant offers several solutions:

- CoroTurn® 107 and CoroCut® 2, in grades S205 and GC1205, offer stability during long machining cycles and help maintain precision.

- CoroMill® Plura HD/HFS, CoroMill® 316 (GC1745 and GC1710), and CoroMill® MS20 (S30T, S40T, 2040) support roughing and finishing of titanium and superalloys, enhancing component production for turbine blades and shafts.

- The CoroMill® Plura Router (2P350 series) is used for edge milling in aero-frame assemblies, ensuring accurate composite fitting.

- The CoroDrill® 862-GM featuring veined polycrystalline diamond (PCD) enhances heat dissipation and wear resistance during drilling in HRSAs and composites.

Supply Chain Efficiency and Digital Solutions

In February 2025, Huw Morgan, Senior Vice President – Aerospace Procurement at Rolls-Royce, said, India is the best solution to supply chain challenges. Our engine volumes are growing at around 20%, and traditional supply chains can’t support it.”

This highlights India’s growing importance in global aerospace supply chains. Minimising downtime and ensuring consistent quality to maintain competitiveness.

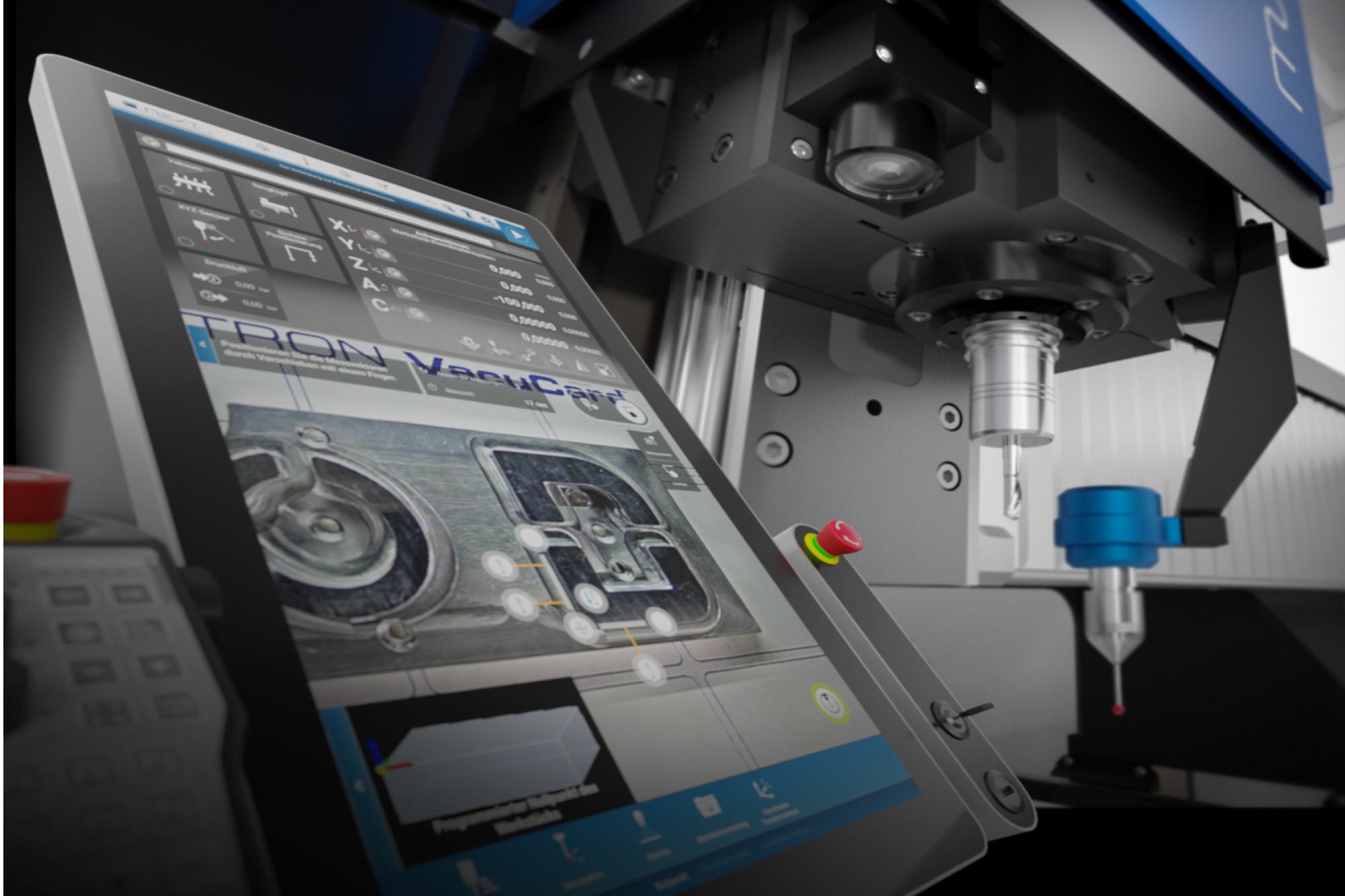

Smart machining platforms such as Sandvik Coromant’s CoroPlus® MachiningInsights provide real-time data and predictive analytics. These tools enable predictive maintenance, reduce the risk of tool failure, and support continuous production.

Other CoroPlus® tools include:

- ToolGuide – helps with tool selection and cutting data.

- ToolLibrary – provides access to over 900,000 cutting tools, streamlining tool setup and production planning.

These digital tools enhance collaboration between manufacturers and OEMs by improving transparency, reducing lead times, and supporting high-quality component production.

India’s aerospace sector is expanding, driven by government policies, global partnerships, and rising demand. The adoption of advanced machining technologies and digital manufacturing platforms, such as those offered by Sandvik Coromant, is enabling Indian manufacturers to produce precision components and build resilient supply chains. These developments are positioning India as a competitive player in the global aerospace market.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.