JumboFlex vacuum tube lifter: good becomes wow!

By Staff Report February 24, 2025 6:47 pm IST

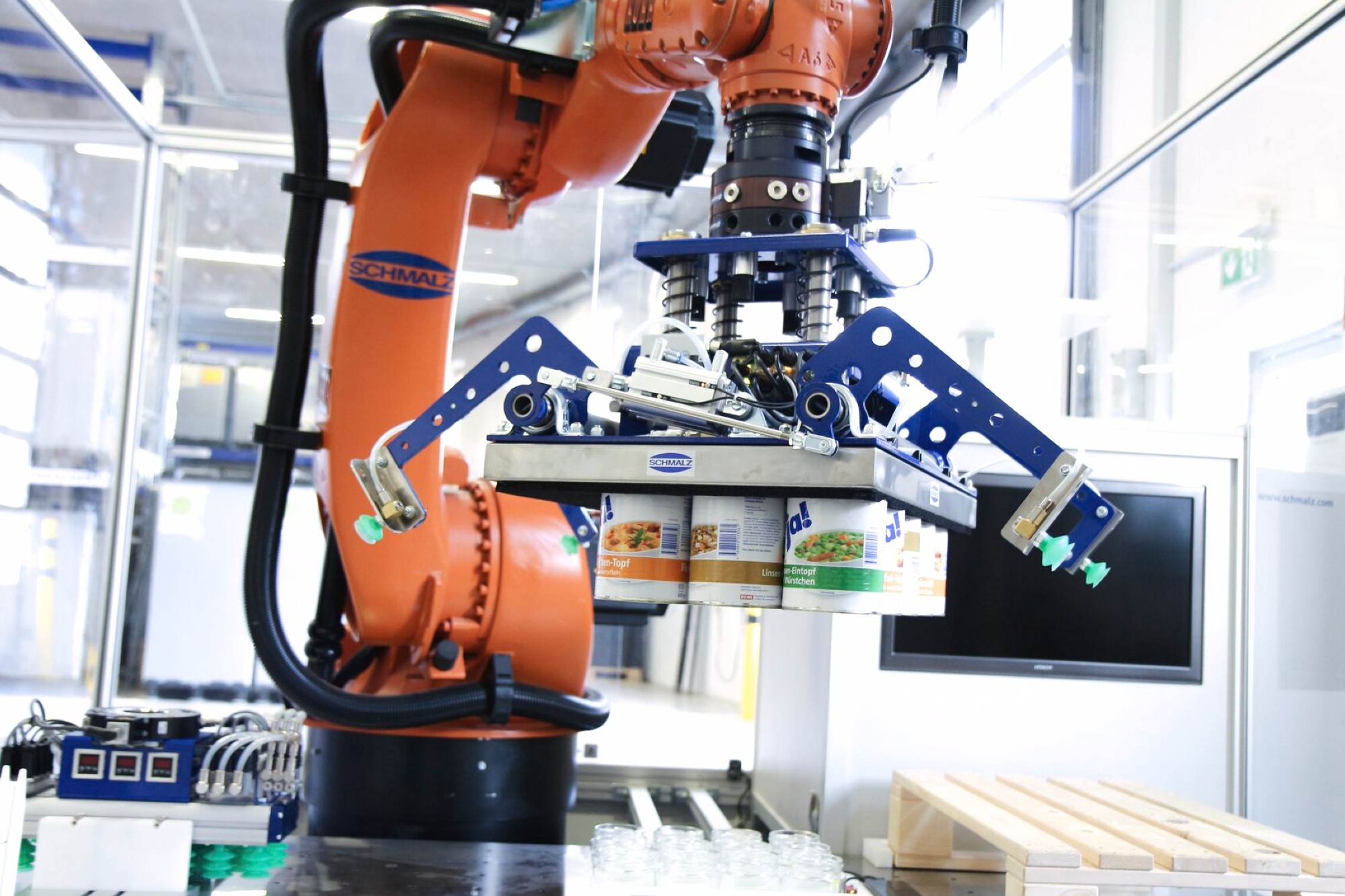

The tried-and-tested JumboFlex optimises handling processes due to smart adaptations. Its handle fits perfectly in the hand – regardless of its size. The redesign makes the vacuum tube lifter intuitive to use and significantly reduces the training time for new skilled workers.

The optimised JumboFlex is suitable for many different hands due to its ergonomic design.

The JumboFlex has been the first choice for many years when it comes to moving workpieces weighing up to 50 kilograms. With its help, employees handle goods ergonomically and with a high cycle frequency. Schmalz is now proving that good things can be optimised with the redesign of the vacuum tube lifter. The new control handle is now even better suited to different hand sizes, allowing small hands to grip just as safely and fatigue-free as larger ones.

The two operating buttons are also new, replacing the single-button control. They control the up and down movement in opposite directions and are intuitive to use, allowing new employees to work productively even faster and direct the tube lifter even more precisely. If required, loads can be brought to a standstill in a floating position at any height, enabling further process steps to be carried out on the workpiece being handled. For example, labels can be easily applied or workpieces checked. The JumboFlex thus counteracts employee fatigue even more effectively than before.

Fast gripper changes with high workpiece variance for seamless processes

With the double-speed gripper change, employees handle different workpieces without interfering with handling processes. The employee can simply slide the end effector into the holder with a flick of the wrist. A simple tweezer handle for releasing the gripper enables really quick changes and prevents accidental release. If the new gripper is not properly engaged, employees receive a visual warning. A rotating mechanism, which is operated via a simple and intuitive slider, allows the workpiece being handled to be rotated 360 degrees or fixed in 90-degree increments.

When configuring the JumboFlex, users can choose between several variants and circuitry. For example, a swivelling function is available for the gripper, which can also suck in the workpiece from the side. An optional display, which is controlled via a foil keypad, informs the specialist about the weight of the goods, for example in the Weight Control version. This saves companies additional weighing, especially when picking in the dispatch area.

With the JumboFlex, companies can offer their employees an ergonomically designed work tool that makes physical work easier, reduces fatigue and increases efficiency. This enables them to position themselves as attractive employers and prevent their skilled workers and employees from leaving the company.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.