Hyundai India drives net-zero future with clean testing technology

By Staff Report June 23, 2025 2:58 pm IST

Hyundai Motor India has tested over 4.25 million engines using zero-emission, fuel-free Cold Bed Engine Testing, advancing its net-zero and green manufacturing goals.

Hyundai Motor India Limited (HMIL), India’s premium provider of smart mobility solutions, has reached a significant milestone in sustainable manufacturing by successfully testing over 4.25 million engines with its revolutionary Cold Bed Engine Testing technology. This approach removes the need for fuel, coolant, and water, allowing for a completely clean and zero-emission testing method.

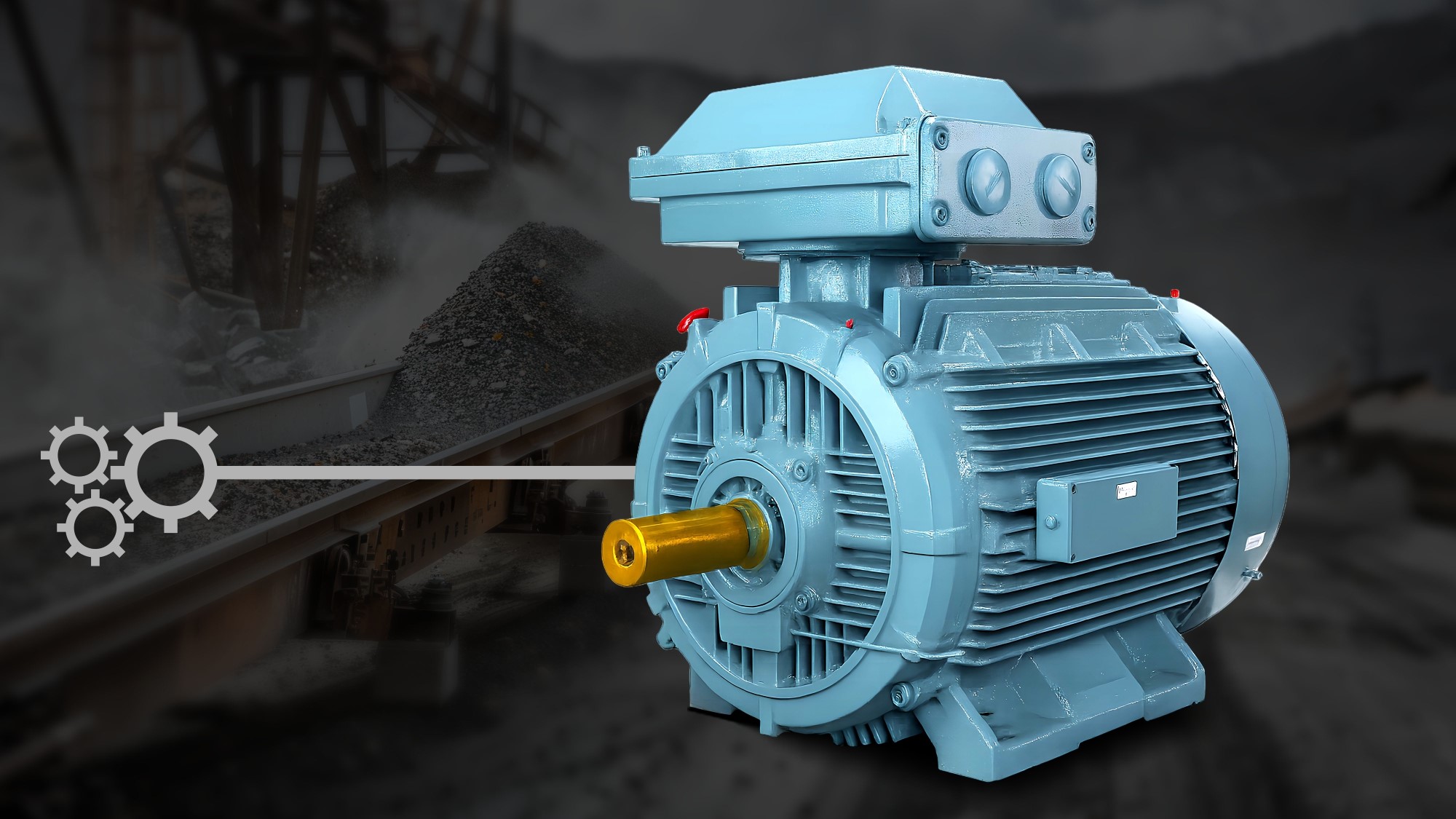

Revolutionising Engine Testing

Cold Bed Engine Testing, which was introduced in 2013, allows HMIL to evaluate engine performance using electricity generated from renewable energy rather than traditional fuel-based methods. The technology employs high-precision sensors to monitor important engine parameters such as crankshaft angle, chamber pressure, and compression, guaranteeing that each engine fulfils strict quality criteria while emitting no emissions.

Gopalakrishnan CS, Director and Chief Manufacturing Officer, HMIL, stated, “At Hyundai Motor India, innovation and sustainability go hand in hand. By testing over 4.25 million engines using zero-emission Cold Bed Engine Testing, we’ve curbed 2 million kg of CO₂ and saved US $1 million, while ensuring world-class quality through our fully automated, fuel-free process. As we mark 30 years of ‘Make in India, Made for the World’, we stay committed to driving a greener, smarter future.”

Environmental and Economic Impacts

Through clean testing, HMIL has reduced CO₂ emissions by almost 2 million kg, contributing to cleaner air and more sustainable mobility. Furthermore, the use of this system has saved the corporation roughly $1 million in operational expenditures by eliminating the requirement for gasoline, coolant, and water during engine testing.

How Technology Works

Cold Bed Engine Testing uses an electric motor to rotate each engine’s crankshaft. Sensors measure engine compression, chamber pressure, crankshaft angle, and other performance characteristics to assess engine worthiness. The completely automated system, which is integrated with Industry 4.0 technology, digitally archives all test data, allowing for future research and development and continual improvement.

Driving a Greener Automotive Future

This fully automated, zero-emission process demonstrates HMIL’s dedication to innovation, quality, and environmental responsibility. Cold Bed Engine Testing, which is part of Hyundai’s global aim to reach net-zero emissions by 2045, demonstrates how sustainable practices are being integrated into production operations to create a smarter, greener future.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.