Universal Robots to boost robot automation in India

By admin August 18, 2016 5:57 pm IST

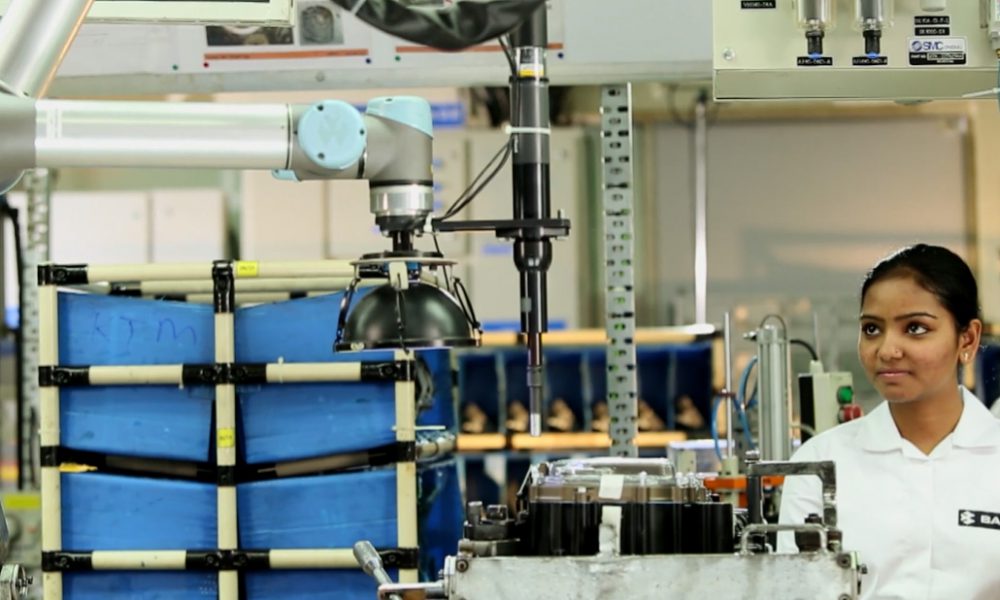

With the aim of making robot automation accessible to all levels of industry, Universal Robots, a Danish robot manufacturer, introduces Cobots in India. In an event held in Mumbai today, the company discussed on the future of co-bots in India and accessibility to such technology that could bring about a revolution in various industries.

Co-bots are designed to work with humans and assist them with a variety of tasks which help to automate and streamline repetitive and potentially unsafe processes thus, ensuring safe work environment while increasing productivity and efficiency. A research conducted by MIT students at a BMW factory, concluded that teams made of humans and robots collaborating efficiently can be around 85% more productive than teams made of either humans or robots alone. Also, the cooperative process reduced human idle time by virtue of its pace-setting ability.

The company has seen the evolution of robot arms from the UR3, UR5 and UR10, which are built for respective payloads of 3kg, 5kg and 10kg.

Universal Robots has been servicing clients in India such as Mahindra, TVS, TATA Consultancy Services, Siemens, Bajaj, BOSCH, Renault, Hindustan Unilever Limited, GE, Calvin Klein to name a few.

Pradeep David, General Manager, Universal Robots (India) further added, “Our three different collaborative robots are easily integrated into existing production environments. With six articulation points, and a wide scope of flexibility, the collaborative robot arms are designed to mimic the range of motion of a human arm. The latest collaborative robot technology should be available to all businesses. The nominal investment cost is quickly recovered as our robotic arms have an average payback period of just six months.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.