Advancement in Flue gas flow rate monitoring

By OEM Update Editorial August 10, 2021 6:39 pm IST

Efficient operation of today’s power plant depends largely upon accurate & repeatable measurement of primary and secondary air flow.

Flue gas or Stack gas emission flow rate measurement is now-a-days important for quantifying emission (CEMS) for environmental reporting for Govt. Authorities for pollution control. Flue gases are gases emitted due to combustion process due to heating of fuel (liquid or solid or gaseous) & Air with a stoichiometric ratio in:

- Boiler Heating

- Process furnaces.

Flue Gas Flow Measurement importance

As most flue gases emission contains air pollutants that are harmful for human health. So continuous emission monitoring systems (CEMS) are mandatory for providing reporting to state & central pollution control boards for environment pollution control. It is important to measure the composition and concentration of polluting gases as well as mass flow rates to arrive at the total emission discharge in the environment.

Flue gas flow rate measurement is imperative for below:

- Optimizing ESP performance by maintaining design parameters such as specific collection area, gas velocity and treatment time within ESP in control.

- Indicates early warning for Preheater condenser failures

- Help regulates harmful pollutants, dust emission controls

- Useful information on optimizing mass balance

- Simple design to operate Helps in energy conservation easily

- Predictive & preventive measures for optimizing their process efficiency and reducing harmful emission in the environment.

Process conditions of Flue gas in Stack:

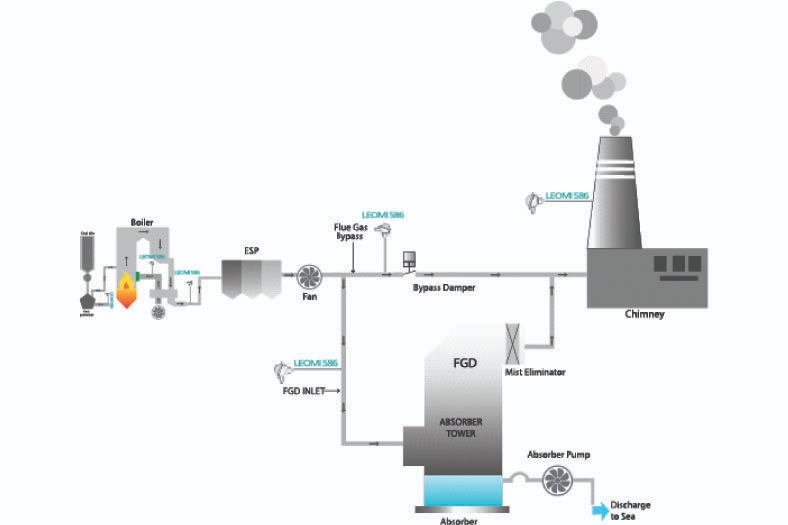

Locations to monitor Flue Gas flow rate

To get the optimum efficiency it can be monitor at:

- Chimney or Stack near to the point of sampling for lab analysis.

- Inlet of Flue gas desulfurization plant (Wet FGD / Dry FGD) in Thermal Power plant

- Process stack in chemical production, fertilizer, steel plants

- Process venting systems.

Main technologies available for Flue Gas flow monitoring

- Differential Pressure based Flow meter (Aerofoil/ Annubar /Pitot-tube)

- Non- Contact Ultrasonic Flowmeter

- Insertion Thermal Mass Flowmeter

Process instrumentation engineer’s task is to identify which of the above will be best suitable technology.

For more info, visit: https://leomi.in/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.