Mechanical and Microstructural Characteristics of Cold Metal Transferred WAAM Steel Components

By OEM Update Editorial November 11, 2021 4:18 pm IST

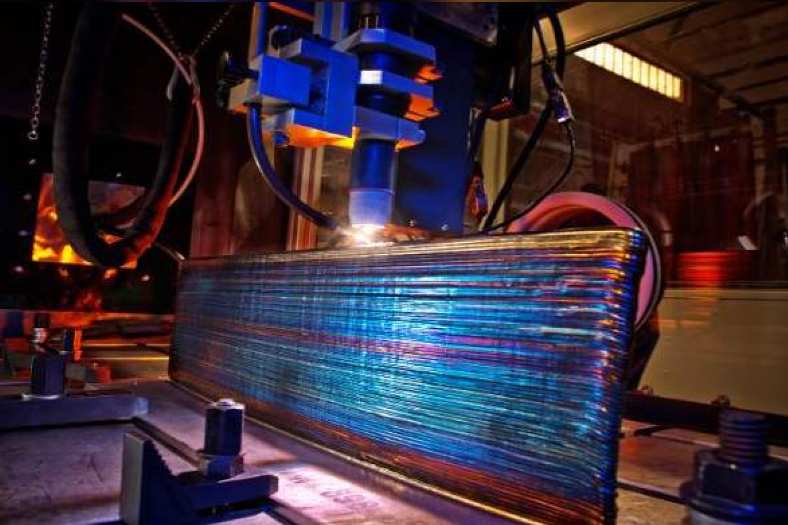

Additive Manufacturing (AM) of metals is an innovative near-net-shaped manufacturing technology used for generating topologically optimised solid objects by depositing successive layers of material using a focused heat source.

According to ISO-ASTM 52900, AM is defined as the “process of joining materials to make parts from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing and formative manufacturing methodologies.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.