NUM include power skiving options to its CNC solutions

By OEM Update Editorial March 20, 2021 12:19 pm IST

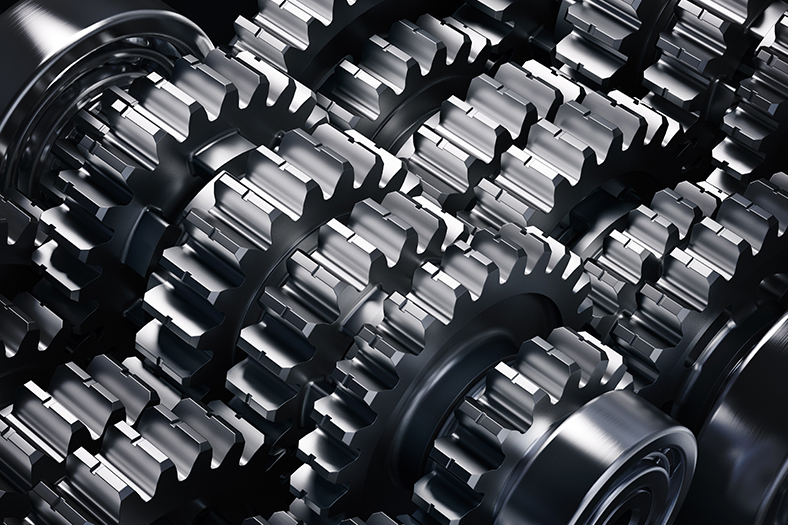

Powerful new software and multi-level electronic gearbox pave the way for next-generation CNC machine tools with combined skiving capabilities. Power skiving is potentially a much faster and more efficient way of creating external and internal gears of any size.

CNC specialist NUM has further extended the functionality of its renowned NUMgear family of gear production technology with the addition of an extremely flexible software option for power skiving.

NUM’s new power skiving option provides the enabling technology for CNC machine tool companies to address a key market opportunity in the nascent compact gearbox manufacturing industry. It is now possible to create an entirely new generation of gear production automation that offers combined hobbing and skiving capabilities on a single machine.

Gear manufacturers currently employ a variety of machining processes including hobbing, shaping, broaching and grinding. To a large extent, the processes used are dictated by the type and size of the gears and splines being produced. Hobbing is ideal for external gears while shaping and broaching are best suited to the production of internal gears but the latter is only really practicable with small gears. Power skiving, on the other hand, is potentially a much faster and more efficient way of creating external and internal gears of any size.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.