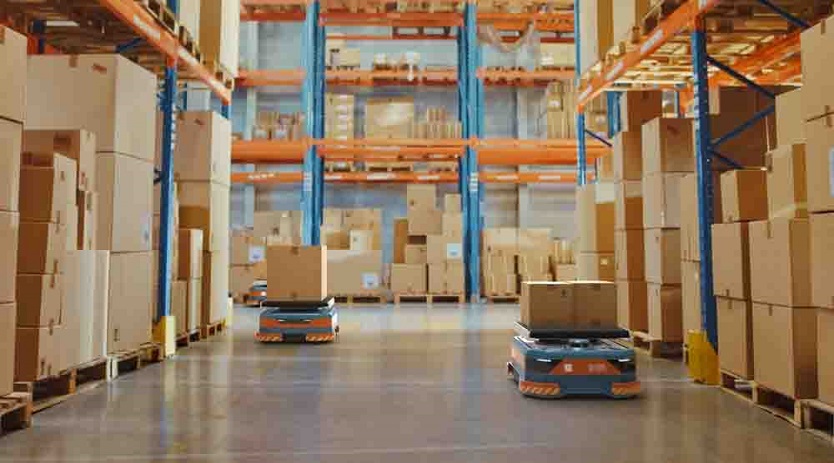

RENATUS ROBOTICS Inc. launches automated robot warehouse system

By OEM Update Editorial December 15, 2022 2:19 pm IST

RENATUS ROBOTICS helps companies run efficient and productive logistics operations with labour cost reductions by up to 67 percent through productivity gains from proprietary optimisation algorithms and cutting-edge hardware automation.

The automated warehouse startup, RENATUS ROBOTICS Inc. has recently launched RENATUS automated robot warehouse system. It enables a single worker to perform picking, consolidating, and packing operations all in one stop, operations that have traditionally required workers and dedicated material handling equipment at each step. This system revolutionises inventory management and order fulfillment in all segments of logistics including e-commerce.

The system is a 3D storage rack system with company’s shuttle and high-speed lifts that operate inside, managed and controlled by the proprietary software and algorithm package RENATUS CORTEX.

The advantages of it includes “One-Stop Pick & Pack” system, unmatched picking efficiency, and ultra-high storage efficiency.

The Ultra-high storage efficiency, traditionally, resolves the issue of congestion and collisions among robots has been a challenge for automated warehouse systems at large scales. With this however, RENATUS CORTEX realizes optimised, collision-free path planning for fleets of RENATUS SHUTTLEs up to 2000 units simultaneously. Communications within the system are done over local 5G for stable, high-speed performance. The combination of both revolutionary software and hardware enables its systems capable of storing 1 million bins and shipping over 300,000 lines per day.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.