Ascentek is investing $50 million in Shreveport to build a new facility, upgrade its plant, and create 91 jobs.

Ascentek, Inc., a pioneer in fluid and lubricant technology, has announced a $50 million investment to build a new 270,000-square-foot manufacturing assistance facility and upgrade its existing production and distribution centre in Caddo Parish. This expansion aims to meet growing global customer demand while strengthening Ascentek’s operations in Louisiana.

The project is expected to create 91 new direct jobs in manufacturing, production support, and business administration while retaining 105 existing positions. Louisiana Economic Development (LED) estimates the initiative will also generate 247 additional indirect jobs, bringing the total to 338 new jobs in the Northwest Region.

Susan B. Bourgeois, Secretary of LED, stated, “Ascentek’s history of impact and innovation aligns with our agency’s new strategic plan, and that is just one reason we are proud to continue our partnership as they renew their commitment to Louisiana and our workers.”

The expansion will feature new high-speed production, material handling, and storage equipment, significantly enhancing the company’s industrial fluid, lubricant, and chemical manufacturing processes. Ascentek’s facility at 7699 W. Bert Kouns Industrial Loop will also benefit from infrastructure improvements designed to boost both community safety and operational capabilities.

Chad Baker, President and CEO of Ascentek, stated, “The buildout of our new manufacturing assistance facility and the improvements to our existing Shreveport site not only broaden how we support our customers but also reinforce our commitment to the Shreveport community. Between job creation, economic stimulation, and future growth, Ascentek is here to create a unique working environment for every teammate who joins the Ascentek family.”

“Ascentek’s $50 million investment is a tremendous vote of confidence in Shreveport’s future,” said Shreveport Mayor Tom Arceneaux. “This expansion will bring high-quality jobs and further strengthen our reputation as a manufacturing hub.”

To secure the project, LED provided a competitive incentive package, including LED FastStart’s comprehensive workforce development support. The company is also expected to participate in Louisiana’s Industrial Tax Exemption and Quality Jobs programmes.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Godrej Tooling is playing a key role in India’s fast-growing EV sector by delivering high-precision dies and tooling solutions. With a focus on localisation and innovation, the company is helping strengthen the EV supply chain while supporting the Make in India vision.

Godrej Enterprises Group’s Tooling division supports India’s rapidly increasing electric vehicle (EV) market by delivering innovative, high-precision tooling solutions. As the automobile industry transitions to EV adoption, Godrej Tooling has expanded its ability to provide high-precision dies and tooling systems for crucial components, including battery boxes and sheet metal parts.

To satisfy expanding demand, the company has invested 2-3% of its income in R&D and modern machinery, resulting in increased innovation and manufacturing efficiency. With May 2025 EV sales up 28% year on year and 1.96 million units sold in FY2025, the demand for domestically manufactured, high-precision EV components has increased. Electric vehicle-related tooling orders currently account for 10-15% of the company’s revenues.

Pankaj Abhyankar, Business Head, Tooling business, Godrej Enterprises Group, stated, “Our focus on precise tooling enables Tier 1 and Tier 2 suppliers to meet EV standards while contributing to the government’s ‘Make in India’ agenda and lowering dependency on imports. India’s EV transformation is about more than just cars; it’s about creating a robust, self-sufficient, and globally competitive ecosystem. We are delighted to help by providing solutions that reduce lead times, increase cost efficiency, and ensure product reliability.”

Godrej Tooling is also looking into localising some of the tools it now manufactures overseas, intending to reduce import dependence, increase exports, and create secondary markets for localised solutions. This combined focus on worldwide servicing and domestic production reflects the company’s desire to establish India as a base for world-class tooling exports.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Electric vehicles are reshaping transportation and challenging traditional automakers. With growing demand and stricter emissions standards, innovation is driving the shift toward cleaner, smarter mobility. Discover five key technologies that are pushing electric vehicles toward greater efficiency, convenience, and sustainability.

Electric vehicles (EVs) are no longer a distant dream; they are transforming transportation today, reshaping the auto industry, and challenging established automakers. Fairfield Market Research predicts remarkable growth for the global electric vehicle market over the next decade. As demand rises and emissions standards tighten, innovation is accelerating this transition. Let’s explore five game-changing breakthroughs that are driving EVs toward greater efficiency, convenience, and sustainability.

Solid-state batteries, which use solid rather than liquid electrolytes, offer higher energy density, enabling ranges of up to 600 miles per charge in prototypes. Their non-flammable materials enhance safety by reducing fire risks. Companies like Toyota and QuantumScape are investing heavily in commercialising these batteries, which promise faster charging without compromising performance and are set to intensify competition in range, cost, and power.

New ultra-fast chargers from networks such as IONITY and Tesla Supercharger V4 deliver over 350 kW, cutting 80% of charging times to as little as five minutes. These systems feature high-voltage designs, advanced cooling, and smart-grid integration to manage demand and prevent overload. This makes EV refuelling as convenient as filling up with petrol, encouraging adoption beyond cities to highways and rural areas.

V2G technology allows EVs to supply electricity back to the grid during peak demand, helping balance supply and creating revenue opportunities for owners. Successful pilots in Europe and California demonstrate its potential. Automakers like Nissan and Honda are integrating V2G functionality into their models. When combined with utility incentives, V2G helps reduce ownership costs and turns EVs into active participants in the energy system.

EVs can now recharge wirelessly through inductive pads embedded in parking spaces or beneath roads. Companies such as WiTricity and Plugless Power offer systems with up to 90% efficiency for home or public use. Dynamic charging on the move tested in Sweden and South Korea extends range for fleets. These solutions eliminate the need for cables and will complement wired fast chargers, making charging simpler and more convenient.

The simpler powertrains and integrated computing of EVs make them ideal for autonomous driving technology. Companies like Tesla, Waymo, and Mobileye are developing systems that enable Level 3 and Level 4 automation using AI-powered sensors. Features like smart summon and valet parking are already enhancing convenience. Autonomous EV fleets promise lower costs and reduced congestion, reshaping the future of mobility.

These innovations – solid-state batteries, ultra-fast and wireless charging, V2G integration, and autonomous driving – are breaking down key barriers to EV adoption and redefining customer expectations. With collaboration across industries, the automotive sector is on the brink of its most significant transformation in a century, delivering cleaner, smarter, and more connected mobility.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

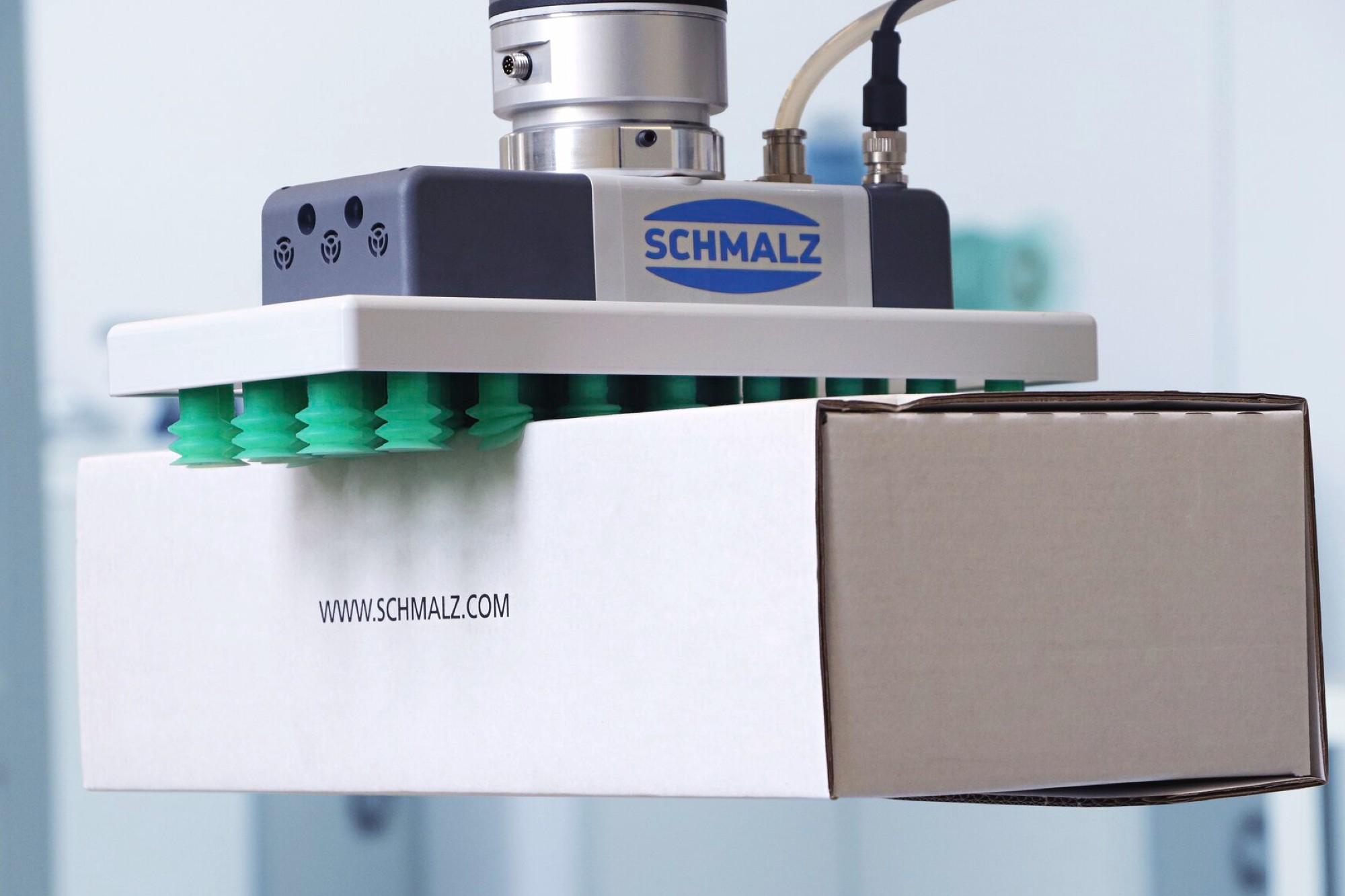

As India accelerates automation, Schmalz gripping systems boost precision, speed, and safety across industries, driving the future of smart manufacturing.

As India rapidly embraces Industry 4.0, automation and robotics are no longer optional—they are essential tools for increasing productivity, ensuring consistent quality, and staying competitive in global markets. Whether in automotive plants, electronics assembly lines, logistics warehouses, or food processing units, robots are transforming how materials are handled, assembled, and packed. But the performance of these robots depends not only on their speed or programming—it hinges on how reliably they can pick, hold, and place parts. This is where gripping systems, especially vacuum-based solutions, play a defining role.

The gripper is the robot’s physical link to the workpiece. It determines how safely a carton, a metal plate, or a glass vial is picked without damage. It affects cycle time, placement accuracy, and whether a robot can switch quickly between different parts or products. A poorly chosen gripper can cause slippage, misalignment, or even production stoppages. That’s why Schmalz, a global leader in vacuum automation, is at the forefront of developing smart, adaptive, and efficient gripping systems for a wide range of manufacturing tasks. Their solutions are not just tools—they are enablers of seamless automation, tailored to meet the growing diversity of Indian manufacturing industries.

In high-speed material flow applications like palletising and de-palletising—common in logistics, automotive, or food & beverage sectors—Schmalz offers the Vacuum Layer Gripper SPZ, engineered to lift entire layers of cartons, cans, or bags quickly and securely. What makes the SPZ unique is its large-area vacuum contact and ability to gently yet firmly grip even slightly uneven surfaces without damaging packaging.

For production environments that require picking and placing varied or fragile items—like electronics boards, glass packaging, or delicate consumer goods—the FQE Area Gripper delivers reliable performance with maximum flexibility. Its broad sealing surface conforms to different product shapes, while the integrated ejectors ensure fast gripping and release cycles. The FQE is also highly compact and lightweight, which allows faster robot movements and energy-efficient operation. Importantly, its smooth contours and safety-compliant design make it suitable for collaborative use, such as in shared workspaces between humans and robots in light assembly or quality inspection cells.

For dedicated collaborative robotics (cobot) applications, Schmalz has developed the FXCB and FMCB series, specially designed to work alongside people. These grippers combine a safe, rounded design with smart functionality—like built-in vacuum generation, lightweight construction from 3D-printed materials, and plug-and-play integration using standard robot flanges. Whether in automotive kitting, pharmaceutical packaging, or food-grade environments, these grippers enable robots to perform repetitive or ergonomic tasks safely while maximising their payload and reach. Their simplicity in setup and quick changeovers allow manufacturers to deploy cobots flexibly, without needing in-depth programming or custom hardware each time a new product is introduced.

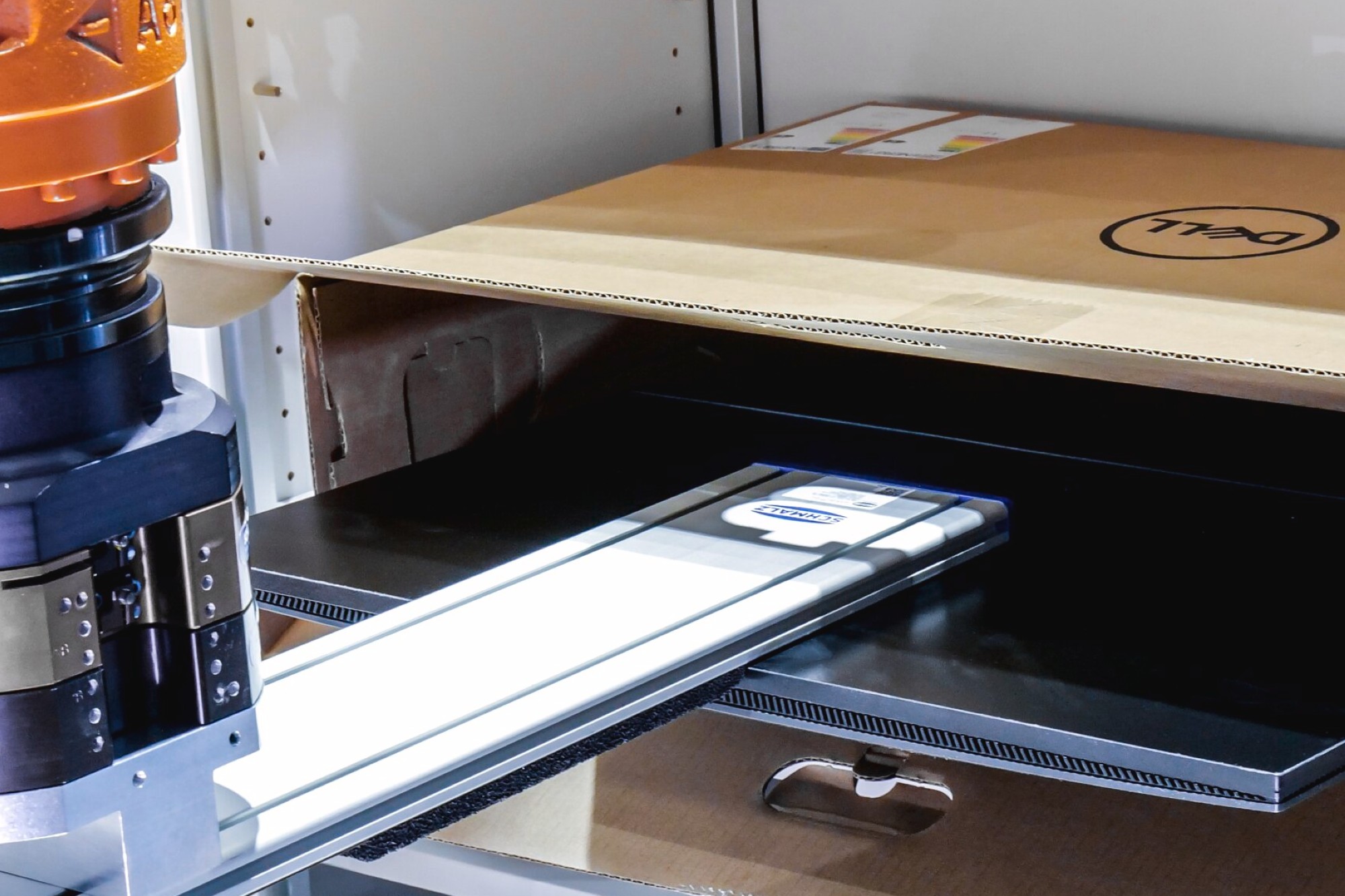

For automation tasks involving flat, sealed workpieces, the Vacuum Area Gripping System FEL offers a lightweight and cost-effective solution. Designed for efficient handling of uniform surfaces, the FEL is ideal for picking items such as delicate electronic components like laptops, tablets, mobiles, small display screens, and flat-glass elements. Its compact design integrates vacuum generation directly within the unit, eliminating the need for external ejectors and simplifying installation—especially in space-constrained robotic arms or gantry systems. The gripper’s rigid housing and replaceable foam sealing pad ensure consistent suction and reliable surface contact without damaging sensitive parts. As a result, the FEL is being used in industries ranging from electronics assembly and packaging to intralogistics and light industrial automation, where ease of integration, cycle-time stability, and part safety are critical.

Meanwhile, the SLG Lightweight Gripper is ideal for customised handling of small components using cobots or compact robotic arms.

Thanks to additive manufacturing, the SLG can be tailor-made to match the shape, spacing, and handling needs of the specific parts being moved. This makes it particularly suitable for electronics, plastics, cosmetics, and consumer goods industries, where product shapes vary frequently. Despite being extremely lightweight, the SLG delivers reliable holding force and supports high-dynamic movements. Its modular, ready-to-connect design speeds up integration, allowing automation experts to quickly deploy and redeploy it across different workstations without sacrificing performance or precision.

What ties all these gripping systems together is the tangible benefit they offer to Indian manufacturers. With Schmalz grippers, users see faster cycle times, fewer product defects, and increased throughput—whether handling 50-gram vials or 50-kg component layers. Their modular and lightweight designs mean easier integration into existing lines, while the robust construction ensures long service life and minimal downtime.

More importantly, these systems reduce physical strain on human operators by automating repetitive, heavy, or awkward manual handling tasks—supporting a safer and more productive shop floor. In a market that demands speed, agility, and reliability, Schmalz gripping systems are enabling the next generation of Indian automation—built on smarter gripping, not just smarter robots.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Lapp India powers industrial efficiency with its SKINTOP® cable glands, delivering safe, durable, and easy-to-install solutions for diverse applications.

LAPP India, a leading producer of cable and connectivity solutions, is redefining industrial cable management with its innovative SKINTOP® range of cable glands. Engineered to meet diverse application needs across both critical and general industrial settings, SKINTOP® delivers customised, high-performance solutions that ensure safety, reliability, and ease of installation.

The SKINTOP® portfolio features two complementary polyamide gland product lines SKINTOP® ST / STR and SKINTOP® SMART designed to meet evolving industrial demands. SKINTOP® ST / STR cable glands are globally certified and ideal for harsh industrial environments such as cleanrooms, energy networks, automation systems, food and beverage, pharmaceuticals, oil and gas, and data centres.

Manufactured from durable polyamide with metric (M12–M63) and PG (PG 7–48) threads, these glands offer a wide clamping range, ingress protection up to IP68 (5 bar/30 min) and IP69, flame resistance up to 650°C, and certifications including CE, UL, DNV, VDE, and UKCA — making them suitable for export-ready, hygienic, and outdoor installations.

The SKINTOP® SMART series, produced at LAPP’s cutting-edge facility in Dharuhera, caters to general-purpose industrial applications such as control panels, junction and array boxes, limit switches, parking systems, and surveillance setups. Compact and easy to assemble, these cable glands support clamping sizes from M12 to M32 and PG 7 to 29, provide robust ingress protection up to IP68, and are UR (UL Recognised) certified to meet local installation requirements.

Sumit Mitra, Managing Director, LAPP India, stated, “Every industrial application has unique cable and connection needs, and at LAPP, we believe the right cable requires the right gland for effective solutions With decades of expertise, we offer a comprehensive range of cable glands SKINTOP® ST / STR for demanding, certified environments and SMART for reliable, high-quality mainstream installations reflecting our commitment to delivering complete, dependable industrial solutions.”

SKINTOP® cable glands provide multiple advantages that address key industrial challenges. They offer IP68 and IP69 protection to prevent dust, water, and contaminants from affecting connections, while their vibration-resistant design secures cables and extends lifespan. The tool-free, intuitive assembly ensures quick installation, reducing downtime.

Available in plastic, brass, and stainless steel, SKINTOP® caters to a wide range of industrial needs. These glands are built to withstand extreme temperatures, UV exposure, ozone, hot water, and aggressive chemicals, making them ideal for sectors such as oil and gas, food and beverage, pharmaceuticals, and marine applications.

From machine tools and robotics to renewable energy and transportation, SKINTOP® continues to help industries achieve safer and more efficient operations through simplified, high-quality cable entry solutions.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

ABB launches LV Titanium motor in India to boost industrial efficiency and cut emissions.

ABB introduced the LV Titanium Variable Speed Motor platform in India, providing industrial users with a compact, plug-and-play solution that combines a high-efficiency motor and variable speed drive (VSD) technology. The platform helps to reduce energy use, prices, and carbon emissions.

The LV Titanium offers IE5 Ultra-Premium efficiency and is a direct replacement for traditional direct-on-line (DOL) induction motors. It is perfect for use in pumps, compressors, and related applications.

Switching to the LV Titanium in a 7.5 kW centrifugal pumping application can save roughly ₹1.8 lakh in annual electricity expenses (at ₹9/kWh) and cut CO₂ emissions by ~14,200 kg (source: Our World in Data).

The LV Titanium is a fully integrated system that combines a high-efficiency permanent magnet motor and a specially built driving module. The compact, axial form is ideal for installations with limited space. It also has a high torque at low speeds and runs quietly.

Plug-and-play functionality eliminates the requirement for commissioning or specific installation because the motor and drive are preconfigured in the factory. The motor has an intuitive control panel, a built-in PLC, and a Modbus RTU interface for simple system integration.

The LV Titanium is available in sizes ranging from 1.5 kW to 30 kW, with intentions to expand into areas including water treatment, chemicals, and food and beverages. Custom solutions are also available.

Stefan Floeck, Division President of ABB’s IEC Low Voltage Motors, stated, “The LV Titanium was created in partnership with customers to achieve energy savings and minimise carbon emissions without requiring difficult installation. This Variable Speed Motor provides excellent performance in a small, user-friendly, speed-controlled motor design that leverages our decades of application experience.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Cummins India launches new BESS to support clean energy transition and strengthen power reliability.

One of the top suppliers of power solutions technology in India, Cummins India Limited (“Cummins”), today announced the release of its Battery Energy Storage Systems (BESS). With this launch, Cummins’ portfolio of sustainable solutions has grown significantly in line with its Destination Zero strategy. The cutting-edge BESS technology is designed to facilitate India’s clean energy transition while enhancing the reliability of the country’s electricity grid.

BESS technology is quickly becoming a dependable and effective way to meet the energy transition requirements of key industries, such as mining, data centers, manufacturing, and commercial real estate.

Shveta Arya, Managing Director of Cummins India Limited, stated, With aggressive climate targets and a swift uptake of renewable energy sources, India’s energy balance is changing. Our Battery Energy Storage System (BESS) is a dependable, expandable, and environmentally friendly solution that facilitates this shift and moves India closer to achieving net-zero emissions by 2070.

Pankaj Kapoor, Vice President, Distribution Business, Cummins India Limited, stated, “With the increasing demand for dependable power, Cummins’ BESS solutions help customers manage energy costs, enhance power quality, and meet sustainability goals — backed by our global expertise and trusted service network.

Key Features of Cummins BESS:

The debut of BESS demonstrates Cummins India’s continued dedication to promoting decarbonisation via reliable and creative power solutions.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

A third of the approximately 500 exhibitors are making their debut at automatica in Munich, Germany, marking a larger participation than in 2023.

automatica—the leading trade fair for smart automation and robotics, is currently underway from June 24 to 27, 2025. The event brings together industry and research in six exhibition halls, offering an unparalleled overview of the latest topics and innovations. The focus is on technical solutions and exchanging ideas on digitalisation and AI, sustainable production, and the future of work. automatica is thus addressing highly relevant issues that the industry is intensively concerned with. Approximately 500 exhibitors from over 30 countries are participating, with a third of them exhibiting at the trade fair for the first time.

Great response from leading companies in robotics and automation

All the key robotics and automation companies have come together in the automatica halls. Alongside the well-known international industry giants that have been using automatica as their leading trade fair for many years, newcomers such as ATI Industrial Automation (Novanta), Delta Electronics, Device Insight, ESTUN AUTOMATION, HANWHA ROBOTICS, HARTING, HD HYUNDAI ROBOTICS, Reis Robotics, RK Rose+Krieger, SAP and Shenyang SIASUN Robot & Automation are also presenting themselves at the event. It is worth noting that Chinese exhibitors have a much stronger presence at the trade fair than ever before. “automatica brings together all the main companies—whether from Europe, Asia or America—and thus represents the entire international market,” says Anja Schneider.

Healthtech focus at automatica

For the first time, automatica is also offering special solutions covering all aspects of the industrial healthcare sector, from enabling technologies to laboratory automation and clinical robotics. Key components of this initiative include the MedTecLIVE Healthtech Pavilion, in cooperation with the MedtecLIVE trade fair, and a two-day MedtecSUMMIT organised by Bayern Innovativ. This offering is supplemented by specific health technology exhibits from exhibitors, curated by VDMA HealthTech. “The robotics and automation solutions of our exhibitors play a prominent role in medical technology,“ says Anja Schneider. “I am all the more pleased that we can now give this application area an appropriate platform and, with the right partners, continue to tap into an attractive visitor target group for automatica.“

A leader on topics thanks to a high-caliber supporting program

One of the highlights of the supporting programme is munich_i, the high-tech platform for AI and robotics, under the patronage of Bavarian Prime Minister Dr. Markus Söder. The high-tech summit, held on Tuesday, June 24, 2025, was accompanied by a special show on robotics and AI, titled AI. Society and the hybrid robotics competition Robothon® are key components of munich_i. automatica is organising munich_i together with the Munich Institute of Robotics and Machine Intelligence (MIRMI) at the Technical University of Munich.

automatica is also being supplemented by an attractive supporting program this year. It includes the Service Robotics Arena and a special show on mobile robotics, titled ‘Mesh-up’. On a course exceeding 600 square meters, companies are demonstrating how driverless transport vehicles and mobile robots from various manufacturers can be operated flexibly and efficiently.

One ticket—three trade fairs

Two parallel trade fairs are supplementing the automatica offering and providing additional stimulus: Laser World of Photonics focuses on photonics components, systems and applications, while World of Quantum is all about trends, innovations and visions in quantum technology. There are already numerous overlaps between the automation and laser industries, and quantum technology holds huge potential especially for industrial applications, for example, through the desired performance of quantum computers. With one trade fair ticket, visitors automatically have access to the other two events.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Speaking at the Maharashtra Industry Dialogue 2025 held at Jio World Convention Centre, Mumbai on 25th June, Hon. Chief Minister Shri Devendra Fadnavis highlighted Maharashtra’s dominant role in India’s industrial growth and its emergence as a top investment destination.

Fadnavis emphasised that Maharashtra is the biggest exporting state in India, excluding oil, and accounts for 31% of India’s non-oil exports. It is also home to 25% of all Indian startups and has the highest number of unicorns and MSMEs in the country.

He stressed the inclusive industrial development across various regions of the state:

The Chief Minister also underlined Maharashtra’s commitment to sustainable development. By 2030, the state aims for 52% of its power to come from renewable sources, while green mining and transportation policies are being implemented, particularly in Gadchiroli, which will also see the planting of one crore trees.

The state’s MAITRI single-window system, developed by MIDC, was lauded for providing end-to-end integration to streamline industrial approvals.

Fadnavis concluded by affirming Maharashtra’s commitment to contributing significantly to India’s goal of becoming a $5 trillion economy and reiterated support for the vision of “Viksit Bharat.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Panasonic Industry showcased its latest automation solutions at the India Warehousing Show 2025, highlighting advanced technologies to boost productivity for Indian OEMs.

Panasonic Industry Division, a significant business branch of Panasonic Life Solutions India (PLSIND), demonstrated its most recent industrial automation advancements at the India Warehousing Show 2025. Reinforcing its expertise in sophisticated technology solutions, the company showcased a wide range of products geared at increasing productivity and operational efficiency for Indian OEMs.

With over 40 years of design and engineering experience, Panasonic Industry continues to provide a comprehensive spectrum of electronic components and automation devices. These include relays, connectors, sensors, wireless connectivity modules, semiconductors, and passive components, all designed to address the changing needs of India’s expanding industrial sectors, including automotive, pharmaceuticals, packaging, warehousing, electronics manufacturing, and textiles.

Tadashi Chiba, Managing Director and CEO of Panasonic Life Solutions India, attended the event alongside the Panasonic Industry Division team, emphasising the company’s commitment to promoting innovation in India’s manufacturing and logistics sectors.

As industrial automation accelerates globally, India is also seeing a dramatic transition. Manufacturers across industries are increasingly using automation to improve quality, efficiency, flexibility, safety, and profitability. In response to these changes, Panasonic Industry Division is introducing technically advanced automation systems on Indian shopfloors to facilitate this transformation.

Key Offers Highlighted:

Factory Automation Solutions:

The division introduced the Network Function Integrated Type HL-G2 Series Laser Sensor, Motion Controller GM1, and MINAS A7 Servo Systems. These components collectively deliver robust machine operation, improved control, error reduction, and higher productivity.

AC Servos & Motors:

Panasonic offers dynamic servo drives across a power range of 50 W to 22 kW. The lightweight, compact design and advanced vibration-reduction features ensure high-precision and stable machine operations.

Industrial Sensors:

The company’s sensor portfolio includes photoelectric, fibre, inductive proximity, measurement, obstacle detection, and area sensors, supporting a broad range of industrial and laboratory automation needs.

Laser Marking Systems:

Panasonic provides fibre and CO₂ laser markers designed for high-precision 2D and 3D applications across various materials. The company was the first to introduce fibre laser marking systems in the industry in 1999.

Programmable Logic Controllers (PLCs):

Panasonic’s PLC range spans from compact models for basic control to high-performance systems with digital/analogue control, network communications, web server functionality, IIoT 4.0 capabilities, and positioning control.

Human Machine Interface (HMI):

Panasonic’s HMI panels are designed to improve operator usability, featuring integrated web server and IIoT 4.0 functions to reduce design and implementation time.

Machine Safety Solutions:

The company offers Type-2 and Type-4 safety sensing devices, including Safety Light Curtains, which comply with international safety standards such as PLe SIL3 and PLc SIL1.

Conductor Bars:

Panasonic’s Conductor Bars provide versatile and efficient power distribution solutions, widely adopted in Japan and China, with a growing footprint across Asia and North America. These are now available in the Indian market, underscoring the company’s commitment to quality and innovation.

Through these offerings, Panasonic Industry Division aims to support India’s vision of modernised, automated, and globally competitive manufacturing ecosystems.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.