Okuma is meeting India’s growing demand for multitasking and 5-axis machines through a comprehensive product range, strong local support, and continuous innovation; Nishant Agrawal, Manager at Okuma India Pvt. Ltd. explains the company’s strategy of balancing global manufacturing standards with the unique demands of the Indian market.

How is OKUMA India balancing global manufacturing standards with the unique demands of the Indian market under a globally local paradigm?

We align with global manufacturing excellence by customising solutions for Indian customers. We also localise service, application engineering, and customer training while maintaining Japan’s benchmark in machine tool quality. This blend ensures responsiveness to India’s cost sensitivity and operational realities without compromising precision or durability.

With India emerging as a preferred manufacturing hub, what strategic investments or capacity expansions has OKUMA India undertaken to meet rising global demand?

We are expanding our global presence by enhancing our sales and service network in key manufacturing centres like Pune, Chennai, Coimbatore, Kolhapur, and Nashik. This strategic growth aligns with India’s emergence as a global manufacturing hub, enabling us to deliver world-class CNC solutions with localised support and faster response times to support increasing demand in aerospace, medical and EVs.

What is Okuma’s long-term vision for the Indian market?

India is strategically important to us, with its rapidly growing manufacturing sector, demand for high-precision machining, and exploration of its industrial base.

Our long-term vision for the Indian market is to drive innovation, improve manufacturing precision, and support industrial growth by integrating advanced technology with local expertise. Through continuous investment in tailored solutions to India’s evolving market needs, we aim to strengthen leadership and deliver exceptional value to our customers.

How does India fit into Okuma Corporation’s global growth strategy?

India is a key player in our corporation’s global growth strategy, serving as a manufacturing and innovation hub. With its dynamic industrial ecosystem and rising demand for advanced machining solutions, India allows us to expand our reach, drive technological advancements, and establish robust partnerships to support the country’s transforming manufacturing sector.

How does OKUMA ensure adherence to international quality and safety standards while catering to regional cost sensitivities and infrastructure limitations?

We ensure compliance with international quality and safety standards by leveraging advanced technology, strict quality control, and global best practices. Simultaneously, we address regional cost sensitivities and infrastructure challenges through localised solutions, efficient processes, and customer-centric innovations—delivering high-quality, reliable, and cost-effective machining solutions.

What differentiates Okuma’s machines from others in the Indian market?

Our machines are renowned in the Indian market for their exceptional rigidity, precision, and long-term reliability. Powered by advanced technology and intelligent automation, we provide high-performance solutions tailored to India’s evolving industrial landscape, ensuring consistent efficiency, accuracy, and quality.

How is Okuma addressing the increasing demand for multitasking and 5-axis machines in India?

We are meeting the growing demand for multitasking and 5-axis machines through a comprehensive product range, strong local support, and continuous innovation. By focusing on the specific needs of Indian industries, we deliver solutions that enhance productivity, precision, and cost-efficiency for complex and integrated machining applications.

Which sectors are in the most demand for Okuma products in India?

In India, we are seeing strong traction in the aerospace, automotive, die-mould, and medical sectors, driven by the need for high-precision, reliable, and multitasking machining solutions. These industries demand advanced capabilities, and our technology excels in accuracy, productivity, and long-term value.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Misumi India and BharatCares upgraded infrastructure at Government Polytechnic Manesar under a CSR initiative.

MISUMI India, a leading Japanese industrial automation component supplier, successfully completed the implementation of its flagship CSR initiative , the “Empower Skill” project at the Government Polytechnic College, Manesar, Gurugram, Haryana. The initiative was carried out in collaboration with BharatCares, the social impact arm of CSRBOX.

The project involved upgrading infrastructure and training machinery in the college, benefiting over 2000 students and faculty members. It included the renovation of the Placement and Entrepreneurship Cell and the installation of training equipment in mechanical, electronics, and communication laboratories, as well as the enhancement of drinking water systems and sanitation facilities.

The Haryana state government marked the completion of the project with an inauguration ceremony attended by key government officials and company delegates.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

TruCut tools ensure the machining world operates efficiently by delivering quality, consistency, and timely service. The quality of TruCut’s products is evident through optimised carbide grades, advanced grinding techniques, innovative tool geometries, and high-performance coatings.

One-stop shop for all cutting tool needs

With over two decades of experience in the cutting tool industry, TruCut’s primary mission is to provide customers with a comprehensive solution for all their cutting tool needs. The company has a strong presence in both domestic and international markets, offering a range of solid carbide and HSS-Co rotating tools. In a competitive world, quality is the ultimate goal. Its commitment to excellence is reflected in every aspect of production and service.

TruCut is proud and confident that its quality and product range will meet all customer requirements, ensuring end users benefit from the same satisfaction the company takes in producing them. Serving customers across India, TruCut provides application support and supplies through its facility in Chennai and an extensive dealer network. The company offers the finest carbide-cutting tools for a wide range of metalworking industries.

Manufacturing facilities

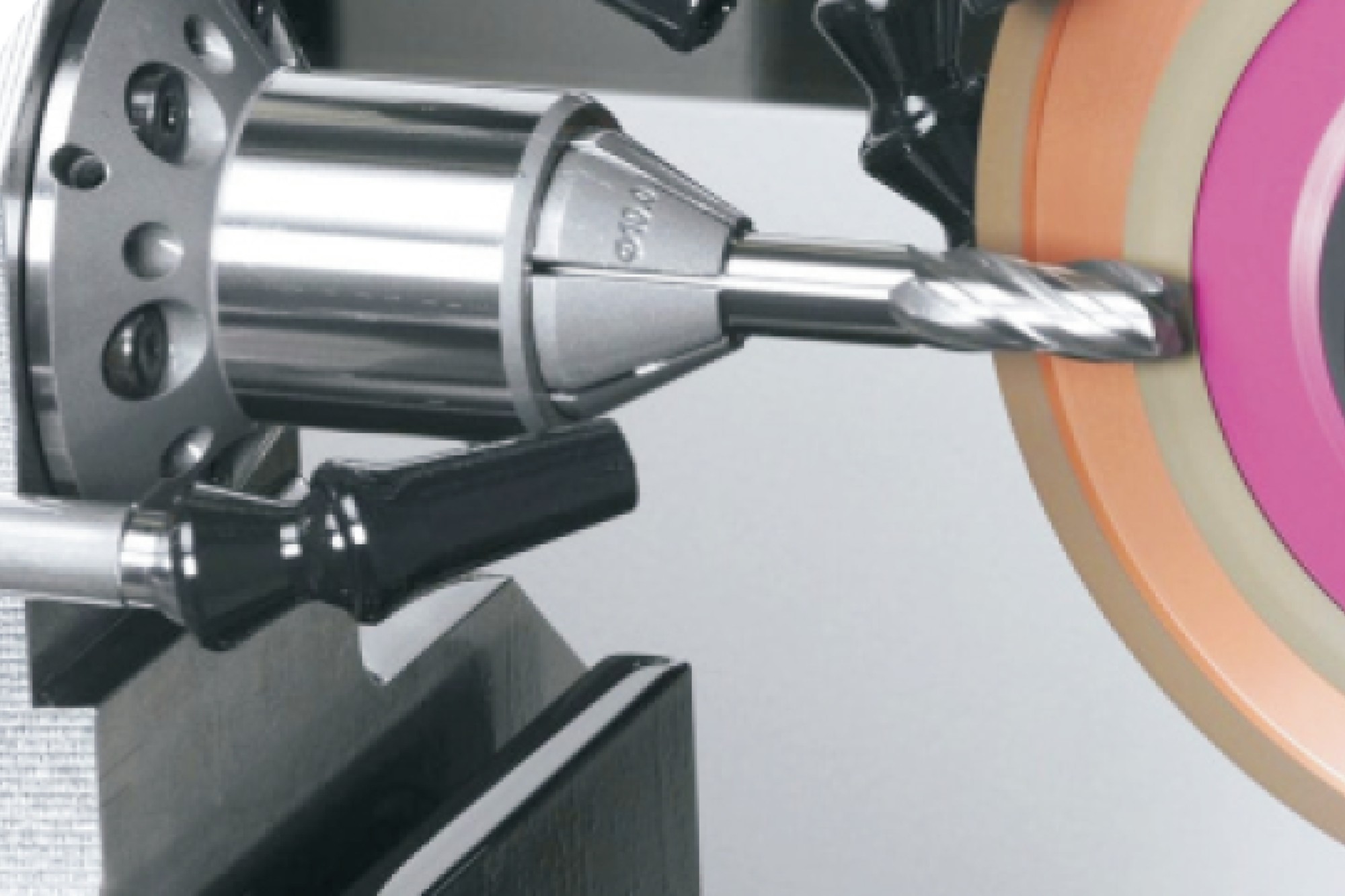

TruCut’s 15,000 sq. ft. production facility in Chennai has advanced CNC grinding and tool inspection machines. Their facility ensures every tool meets stringent quality standards. TruCut benefits towards customers resulted in significant savings and increased productivity over time.

TruCut has installed CNC 5-axis and 7-axis grinding machines for consistent tool performance. A non-contact 5-axis CMM tool inspection machine is used for consistent geometry and dimensional accuracy and laser permanent identification. High-quality, single-piece packaging is used for optimal tool protection. For identification, laser marking is employed on each tool, and high-quality single-piece packaging is used to provide the best protection for every tool.

TruCut uses high-grade microfine and ultrafine carbide raw materials, along with HSS-Co imported from Europe, to ensure consistent quality. They also operate an in-house forming section from underground carbide blanks.

Quality control measure

TruCut tools ensure the machining world operates efficiently by delivering quality, consistency, and timely service. With an extensive inventory of catalogue tools available for same-day dispatch and custom tools offered with minimal lead times, the company responds swiftly to diverse machining needs. The quality of TruCut’s products is evident through optimised carbide grades, advanced grinding techniques, innovative tool geometries, and high-performance coatings. Every tool undergoes rigorous inspection and quality control to ensure consistent performance. As a result, TruCut tools meet the highest standards required in industries where precision and reliability are essential.

TruCut invests in advanced tool production equipment supported by state-of-the-art inspection machines and micro-level inspection procedures to ensure that each tool meets the highest standards of accuracy.

Industries they serve

TruCut is the ideal partner for the development and production of primary and secondary aircraft components. The company offers a comprehensive range of solid carbide tools for metal and composite materials, available globally from a single source. TruCut delivers flexible machining solutions for the aerospace industry, setting new benchmarks in productivity and process reliability, backed by strong technical support.

For machining automotive parts, achieving the highest possible production at the lowest possible cost is essential. This is how TruCut delivers this promise by focusing on reducing long-term, overall process costs rather than simply offering low-cost tools.

TruCut is a leading die & mould industry company that combines decades of experience in tool-making with a forward-looking product portfolio and continuous process chains for individual manufacturing solutions.

The general engineering segment comprises job shops, contract manufacturers, electronic component producers, and those who contribute to the manufacturing world. TruCut supports these businesses by providing innovative solutions that improve their regular processes and help achieve more efficient reliable output.

Industry-specific solutions

TruCut provides tailored solutions for various industries, catering to the needs of each sector. TruCut tools are known for their ability to achieve high production rates at the lowest possible costs in the industry. They are committed to helping customers reduce machining costs. The company designs individual manufacturing solutions with continuous process chains, ensuring efficiency and precision. Offering a wide range of solid carbide tools for superalloy and composite materials, TruCut provides flexible machining solutions that set new standards in productivity and process reliability.

TruCut adheres to its 5-TS (TruCut Standard) to ensure high-quality and consistent products by:

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

ZF Group inaugurated a manufacturing facility in Coimbatore to produce components for construction and rail, supporting local and global supply.

ZF Group, a global automotive supplier and technology company, inaugurated a new manufacturing plant in Coimbatore, Tamil Nadu. The plant focuses on serving the construction and railway sectors.

The facility spans 10,000 square meters and is part of ZF’s ‘Make in India for India and the World’ strategy. It will support domestic demand and contribute to exports for global customers. ZF invested €20 million (₹192 crore) in the plant to support India’s construction equipment segment and meet local demand for technology and solutions.

Dr Peter Laier, Member of the ZF Group Board of Management, stated, “As we inaugurate ZF’s new manufacturing plant in Coimbatore, it is another step in ZF Group’s commitment to India’s manufacturing landscape. India is a strategic market for ZF Group. This facility aligns with our strategy of growth closer to customers.”

Akash Passey, President, ZF Group India, commented, “India is a manufacturing hub for ZF. Our strategy, ‘Make in India for India and Make in India for the World’, is aimed at supporting both domestic growth and global manufacturing.”

Andreas Moser, EVP Industrial Technologies, ZF Group, stated, “India’s construction sector is growing due to urbanisation and infrastructure development. The ERGOPOWER transmission and MULTITRAC axle series produced at the Coimbatore plant support growth and meet domestic and export demands. This plant will work in coordination with ZF’s main hub in Germany.”

The ERGOPOWER M transmission has been industrialised at the Coimbatore site. This automatic-powershift transmission is used in various construction machinery and is designed to support productivity and fuel efficiency improvements of up to 15%.

The plant produces MULTITRAC series axles, which are built for heavy-duty construction equipment. The axles come in different configurations, including various gear ratios and brake systems. They use wet multi-disc brakes to improve efficiency by reducing braking losses.

ZF localised the production of the EcoMet transmission for the Indian railway sector at this facility. The modular gearbox is designed to meet the needs of various metro systems without requiring extra development or production costs.

ZF’s Coimbatore plant supports the company’s plan to strengthen manufacturing capabilities in India and contribute to global supply chains through localised production.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Samvardhana Motherson expands beyond automotive, growing aerospace business fivefold to become a tier-1 Airbus supplier.

Samvardhana Motherson International Ltd (SAMIL) expanded its aerospace business fivefold in a year and emerged as a Tier-1 supplier to Airbus. SAMIL increases aerospace revenues from ₹339 crore to ₹1,749 crore in FY25. SAMIL supplies parts for aircraft models like the A320, B737, and the complete range of LEAP engines. Its aerospace order book is nearly US$1.2 billion over the next five years.

SAMIL is establishing a greenfield unit to produce components employed in machinery for the production of semiconductor chips, which are used in the production of silicon wafers. SAMIL’s vertical expansion of capabilities evolved in the aerospace business. The new unit will also serve the electronics and advanced manufacturing sectors.

Vaman Sehgal, Deputy CEO of SAMIL, stated, “The aerospace business, which we started in this five-year journey, has already grown 5x in a year, and today we are proud to say that we are a Tier-1 supplier to Airbus. Building on the capabilities of the aerospace division, we are setting up a new greenfield to supply components for equipment used to manufacture silicon wafers. We are pivoting these industries to be serving some of the other customers, such as semiconductors and things like that.”

The company is adding consumer electronics and defence segments to diversify out of the auto industry. SAMIL has prepared a capital expenditure of ₹6,000 crore in FY26, 70 percent of which is to be used in non-auto segments.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Seco is implementing circular solutions to reduce waste, extend product life, and support sustainable manufacturing.

Seco is building circularity in all operations to stimulate sustainability in production. Seco concentrates on creating, maintaining, and recovering value through product design modification, business model innovation, and resource use management.

Malvina Roci, Circularity Manager at Seco, stated, “Circularity pushes us to explore innovative solutions across our entire value chain. We’re deepening our understanding of circular opportunities, from exploring new business models and collaborating with our supply chain to extending product life, optimising resource use, and ensuring efficient resource recovery.”

Seco designs products for durability, repairability, and reuse. The company incorporates recycled and recyclable materials early in the design phase. It provides reconditioning capabilities that assist in tool life extension, minimise environmental footprint, and save customers money.

To support circular aspirations, Seco introduced data matrix codes for inserts and round tools to facilitate traceability. “Traceability plays a key role in reducing underutilised tool capacity and optimising tool longevity,” Roci said. “It enables us and our customers to make informed decisions, such as determining the optimal cutting data or knowing when to recondition tools.”

Seco aims to achieve 90% circularity in products, packaging, and waste by 2030 through collaboration with suppliers and customers.

Roci added, “Circularity is not just an environmental necessity, it’s a fundamental shift in manufacturing. By rethinking how we design, use, and recover materials, we are building a more sustainable future.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Nidec starts operations at a new facility in Hubballi, Karnataka, aimed at supporting multiple industrial sectors and generating employment in the region.

In Hubballi, Karnataka’s Dharwad-Beluru Industrial Area, Nidec Corporation inaugurated a ₹600 crore manufacturing plant. M. B. Patil, the Minister for Large and Medium Industries of Karnataka was present at the launch.

With aspirations to scale up to 3,000 employees as operations grow, the factory will initially employ 800 people. Data centres, battery storage, renewable energy, electric vehicles, and general industries are among the businesses it is expected to benefit from.

“This unit will bolster local manufacturing, enhance R&D capabilities, and improve supply chain reliability,” stated M.B. Patil during the launch event.

The facility will produce machines with power capacities of two MW, three MW, and four MW, using technology from Japan and France. Output will be distributed across domestic and international markets, including the US, UAE, and Europe. Nidec will manufacture EV motors, elevator motors, wind generators, power backup systems, and electronic drives for medium and low-voltage applications. The state government has allotted 20 acres to Nidec for a future battery solutions unit.

The facility expected the new plant would significantly contribute to northern Karnataka’s industrial growth and position the area as a major hub for innovative manufacturing.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The Government of India introduced a landmark scheme to promote domestic manufacturing of electric passenger cars.

The Indian government introduces a new policy to encourage the production of electric passenger cars domestically as part of its larger drive for self-reliance, economic growth, and clean mobility. The Ministry of Heavy Industries (MHI) is leading the programme and aims to draw in international EV manufacturers and solidify India’s standing as a major force in the global automotive industry.

The scheme was formally announced on March 15, 2024, and was named the Scheme to Promote Manufacturing of Electric Passenger Cars in India (SPMEPCI). In order to support long-term industrial development and technological cooperation in the EV industry, it lays forth a system of incentives, investment thresholds, and regulatory provisions.

Key Provisions and Objectives

With a 15% customs tax rate reduction for imported electric four-wheelers (e-4Ws) with a minimum CIF value of USD 35,000, the programme incentivises both foreign and domestic manufacturers to invest in India. This five-year concessional tariff is capped at 8,000 automobiles per year. It is possible to carry over any unused import quota.

Applicants must invest a minimum of ₹4,150 crore (about USD 500 million) over three years in order to be eligible. Establishing e-4W manufacturing infrastructure and achieving the well-defined Domestic Value Addition (DVA) goals of 25% within three years and 50% within five years must be the main goals of the investment.

The programme specifies defined guidelines for acceptable capital expenditures, which include new plants, machinery, equipment, utilities, and engineering R&D. While structures associated with core activities and EV charging infrastructure are largely covered under restrictions, land investments are not.

Compliance and Safety Measures

To ensure compliance, successful applicants must produce a bank guarantee equal to ₹4,150 crore or the amount of customs duty forgone. For the duration of the programme, this assurance must be upheld.

DVA certification will follow the procedures outlined in the Production Linked Incentive (PLI) Scheme for Automobiles and Auto Components. MHI-approved organisations will conduct all accredited assessments.

Eligibility requirements

These indicators must be backed up by the most current audited financial statements. Group companies with at least 26% cross-holdings are also welcome to apply.

Application Process

The ministry will soon launch an application window for interested manufacturers. The initial window will be open for at least 120 days, with the prospect of reopening on March 15, 2026. A non-refundable application fee of ₹5 lakh applies.

Aiming for a Greener Future

Union Minister Shri H.D. Kumaraswamy stated the scheme’s transformative aspect during a recent press briefing, pointing out its compatibility with India’s climate objectives and industrial aspirations. He highlighted it as an important step towards achieving the aims of Make in India and Aatmanirbhar Bharat, as well as establishing the basis for India to become a worldwide EV manufacturing hub.

With the policy in place, India hopes to not only increase EV manufacturing but also spur innovation, create jobs, and reduce reliance on fossil fuels, paving the way for a cleaner, more self-sufficient automotive future.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

LAPP India is at the forefront of the smart warehousing revolution, delivering advanced cabling and connectivity solutions that power the next generation of automated logistics.

According to recent data, the Indian smart warehousing market is valued at approximately USD 2.93 billion in 2023. It is projected to reach USD 6.66 billion by 2030. This growth is driven by technologies and modern warehouse solutions such as automated storage and retrieval systems (ASRS), autonomous mobile robots (AMRs), and sensor-enabled conveyor networks. At the core of these advancements are high-performance power and control cables, data cables, and connectors that ensure uninterrupted communication and power supply. These innovations are replacing outdated manual processes to reduce errors and improve productivity.

One of the enablers driving the future of a Smart warehouse is the seamless exchange of real-time data. In a fast-paced business environment, organisations must instantly track inventory fluctuations and swiftly respond to changing production orders, among other dynamic demands. However, this capability hinges on one critical factor: a robust and reliable cabling infrastructure, which ensures seamless data transmission, zero errors in data transfer, and no downtime.

At LAPP, we understand that high-performance data networks and power transmission systems are the foundation of modern logistics. Reliable power and data communication are crucial in automated logistics systems. High-performance equipment, such as industrial-grade data cables, power cables, and connectors, is critical for keeping systems operational and maintaining consistent signals for rapid decision-making, especially in high-volume logistics hubs in India.

LAPP offers high-performance industrial cables and connectivity solutions that ensure fast and safe power and data transmission between various supply chain elements, enabling smooth coordination and control. For instance, LAPP Harnessing Solutions provides customised solutions for many industrial applications, from motion-intensive robotic arms to modular systems for smart logistics. These deliver robust and reliable performance under extreme warehouse conditions. They are halogen-free, oil-resistant, and UV-resistant and come with a wide range of certifications, making them ideal for Smart warehousing applications. Even the most advanced automation solutions cannot function effectively without seamless data connectivity.

Smart warehouses enhance efficiency and improve workplace safety. Automation enables faster order processing, optimised resource management, and reduced workplace accidents. AI-driven solutions handle repetitive tasks like order picking and inventory replenishment, freeing up employees for more strategic decision-making. However, the power and control infrastructure must be equally advanced to function efficiently. LAPP’s cabling solutions, including its Harnessing Solutions, SKINTOP® Cable glands, SILVYN® Conduits, and EPIC® Connectors, ensure stable power delivery and minimise downtime. SKINTOP® Cable glands ensure secure connections, preventing accidental disconnections and minimising exposure to environmental hazards.

SILVYN® Conduits provide enhanced mechanical protection, ensuring cables remain durable in high-movement areas. EPIC® industrial connectors support modular plug-and-play connectivity for seamless integration of automation equipment. This results in a safer work environment where machines handle dangerous or strenuous activities, reducing the risk of workplace injuries.

Smart warehousing on E-Commerce

India’s robust e-commerce market is one of the biggest beneficiaries of Smart warehousing. With the increasing demand for faster deliveries and higher order volumes, businesses are adopting ASRS for automated inventory management, AMRs for autonomous navigation, and advanced conveyor systems for efficient material handling.

However, these advanced systems require reliable, seamless data connectivity and robust power infrastructure. The harsh warehouse environment, constant motion, extreme temperatures, and mechanical stress put cables at risk. LAPP’s robust and resilient cables, combined with industrial Ethernet solutions, ensure zero errors in data transmission and uninterrupted connectivity, keeping automation running at peak efficiency.

Future-ready warehousing

The rapid evolution of intralogistics demands scalable, future-ready solutions. Any new system or upgrade must anticipate future expansions and changes in production demands. From sensors that integrate with new software platforms to data cables capable of handling higher bandwidths, selecting long-term, adaptable components is critical to maintaining competitiveness in an increasingly dynamic yet complex market.

Smart warehousing offers a robust framework for India’s evolving logistics sector, blending automation, real-time analytics, and intelligent connectivity. Driving operational excellence while meeting the need for speed, accuracy, and transparency is essential in a geographically diverse and fast-growing digital economy.

LAPP plays an active role in this transformation, providing innovative connectivity solutions that ensure seamless data transmission, power supply, and future-proof scalability. Choosing the right infrastructure, from cables and connectors to entire drag chain systems, plays a decisive role in successful deployment.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Welcome to OEM Weekly News, your go-to source for the latest updates and innovations in the original equipment manufacturing industry.

Don’t miss the critical information that can help drive your business forward.

Subscribe to our channel and hit the notification bell to stay updated with our weekly news.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.