HMS Networks has officially recognised Red Lion and N-Tron as product brands, providing a single trusted source for automation engineers and system integrators worldwide.

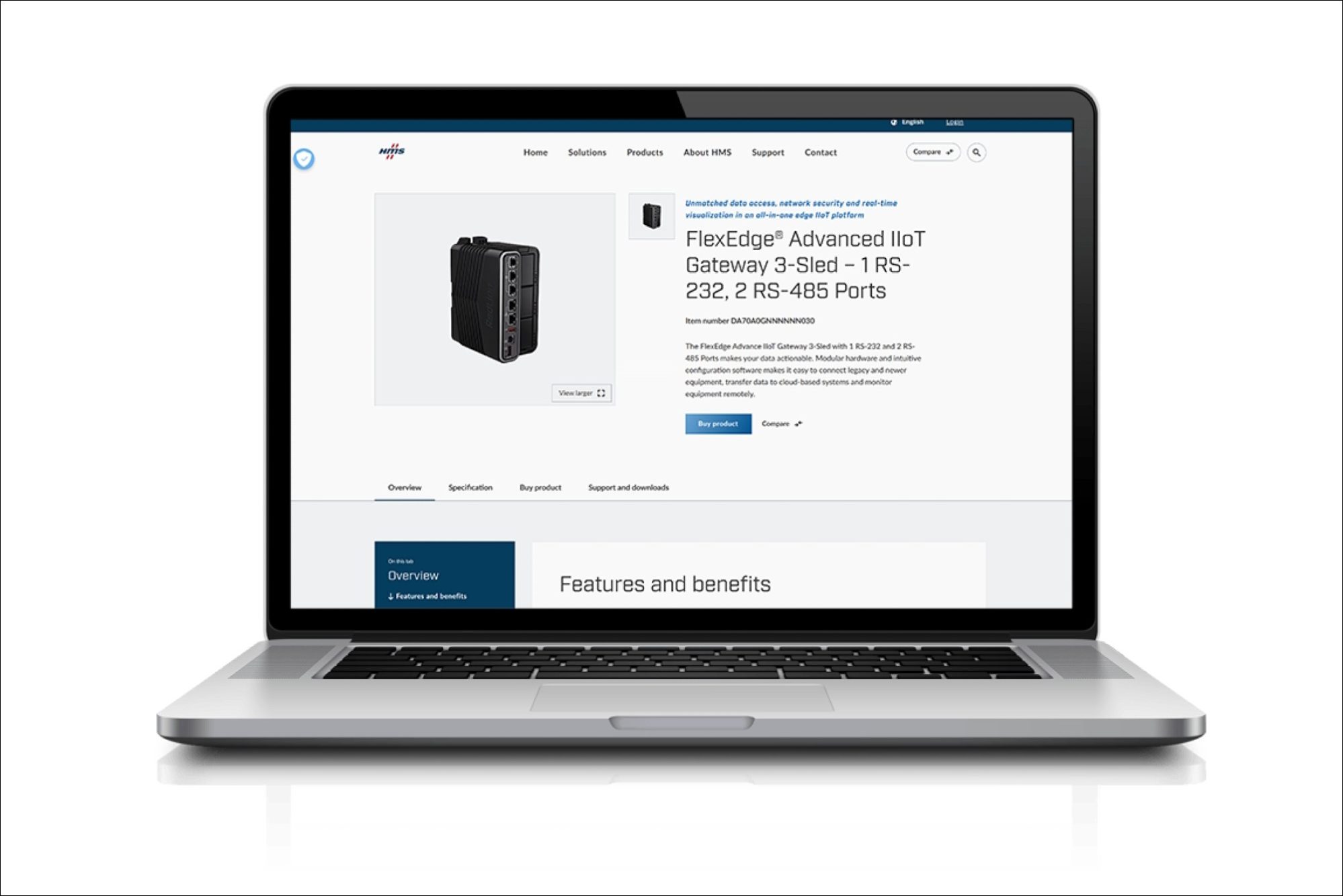

HMS Networks announces that Red Lion and N-Tron are now officially recognised as product brands of HMS Networks. For thousands of automation engineers and system integrators worldwide, this means that scalable industrial solutions for cloud connectivity, edge intelligence, asset management, industrial Ethernet switches, panel meters, and operator panels are now available from a single trusted source, presented on hms-networks.com.

Following the 2024 acquisition of Red Lion Controls Inc., HMS and Red Lion teams have worked together to integrate their offerings seamlessly. The result: two trusted brands — Red Lion and N-Tron — are now under the HMS umbrella, offering enhanced value and streamlined access to industrial connectivity solutions.

Unified brands, expanded capabilities.

Red Lion® by HMS Networks will offer scalable industrial solutions for cloud connectivity, edge intelligence, and asset management, as well as rugged operator panels and panel meters—designed to deliver real-time data visibility, especially in demanding environments.

N-Tron® by HMS Networks will focus on rugged industrial Ethernet switches, providing secure reliable connectivity for industrial networking.

Existing HMS and Red Lion customers will continue to enjoy their trusted purchasing channels and integration partners. Now, they will benefit from a more integrated product offering.

Red Lion control panels can be paired with remote access solutions from Ewon®. N-Tron switches will complement HMS’s robust offerings in network connectivity and diagnostics. The complete portfolio supports secure edge and cloud communication built on HMS’s 30-year track record in industrial networking.

With manufacturing in Sweden and the U.S. and operations in 20 countries, HMS offers local support, technical expertise, and reliable distribution. The entire HMS product offering now includes the product brands Anybus, Ewon, Intesis, Ixxat, N-Tron and Red Lion.

Alexander Hess, Senior Vice President of the HMS division for Industrial Data Solutions, said, “With the Red Lion and N-Tron product brands, we can offer our customers more choices and a seamless experience. By aligning these brands under the HMS umbrella, we’re making it easier for automation engineers and system integrators to build smarter, more connected industrial systems. This means faster deployment, better support, and solutions that work better together.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

With cutting-edge products, intelligent services, and a focus on reliability, Mobil™ reaffirms its commitment to performance partnerships with India’s plastics industry.

At Plastasia 2025, Mobil™, a global leader in lubrication technology, delivered a compelling showcase that resonated strongly with the evolving needs of India’s plastics and polymer industry. With a clear focus on innovation, reliability, and performance, the brand presented an integrated suite of high-performance lubricants and intelligent services designed to empower manufacturers in their pursuit of efficiency and resilience.

Driving operational gains through advanced lubricants

A major highlight of the showcase was Mobil’s industry-leading hydraulic oils, notably the Mobil DTE 10 Excel™ Series and the Mobil DTE™ 20 Ultra Series. These fluids are engineered to address modern plastics machinery’s high-load, high-precision demands.

Based on controlled testing, Mobil DTE 10 Excel™ Series stood out for its ability to improve hydraulic efficiency by up to 6%*. This translates directly into smoother equipment performance, reduced energy consumption, and longer oil and filter life, benefits that help lower operating costs and reduce downtime.

Complementing this, the Mobil DTE™ 20 Ultra Series was featured for its exceptional wear protection and deposit control capabilities. It is well-suited for high-stress manufacturing environments where uninterrupted operation is critical.

Smarter services for cleaner, more reliable operations

Beyond its product range, Mobil highlighted its MachineXT lubrication management service—a specialised offering that addresses one of the industry’s most persistent challenges: oil contamination. By ensuring oil cleanliness and maintaining system integrity, MachineXT helps extend the life of critical components, reduce unplanned shutdowns, and boost overall system reliability.

Also on display was Mobil Lubricant Analysis (MLA), a powerful digital diagnostic tool that delivers actionable insights from oil condition data. Through faster and data-driven analysis, MLA helps maintenance teams make informed decisions, extend equipment life, and optimise performance.

Together, these products and services represent Mobil’s holistic approach to supporting the plastics sector through high-performance fluids and becoming a true performance partner to manufacturers.

Engaging the market through meaningful brand strategy

Mobil’s commitment to India goes beyond the showroom floor. With the plastics sector poised for exponential growth, ExxonMobil has strategically aligned its brand and marketing efforts to better engage with manufacturers, OEMs, and end users nationwide.

Central to this approach is the ‘Fill with Mobil™’ campaign, a brand narrative that goes beyond product features to underscore the trust, expertise, and collaborative spirit that Mobil brings. It positions the company as a lubricant supplier and a dependable ally in achieving higher operational standards.

Backed by over 35,000+ OEM endorsements, Mobil continues to deepen its integration into the Indian machinery ecosystem, reinforcing compatibility and trust across platforms commonly used in plastics manufacturing.

Leveraging Plastasia as a strategic industry touchpoint

For Mobil™, Plastasia is more than just an exhibition; it’s a platform for high-impact conversations with processors and equipment builders. The event enables the company to showcase its strong OEM collaborations, engage with decision-makers on the shop floor, and gather real-time insights that inform future innovations.

The show also emphasises Mobil’s role in supporting manufacturers across India to shift towards smarter, cleaner, and more resilient production ecosystems.

A value chain built for India’s growth

Mobil’s contribution to India’s industrial progress extends across its value chain. The brand supports multiple critical sectors, from manufacturing and mining to plastics and power, enabling higher productivity, lower maintenance costs, and improved system performance.

Its lubricant technology is backed by a robust local supply network and technical centres that work closely with OEMs and manufacturers to deliver tailored solutions for Indian operating conditions.

Beyond lubricants, ExxonMobil’s chemical products also play a pivotal role in various industries, such as pharmaceuticals, water treatment, food processing, agriculture, and construction. Through its signature polymers and specialised materials, the company is helping Indian manufacturers produce high-quality, durable goods for domestic and global markets.

As India accelerates its journey to becoming a global manufacturing hub, Mobil™ remains committed to empowering that transformation, one drop of performance, one partnership, and one breakthrough at a time.

(Exxon Mobil Corporation has numerous affiliates, many of whom have names that include ExxonMobil, Exxon, Esso, and Mobil. For convenience and simplicity, those terms and references to “corporation,” “company,” “ExxonMobil,” “EM,” and other similar terms are used for convenience. They may refer to one or more specific affiliates or affiliate groups.)

For more information, visit www.mobil.in/business

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Pilz believes that an early, holistic approach to safety and security in the hydrogen industry guarantees protection. With automation solutions, hydrogen can be utilised safely and economically throughout the value chain, from its production in electrolysers to storage, transport, and use in fuel cells or industrial burners.

Hydrogen: Safe energy carrier or explosive challenge?

Hydrogen is considered the energy carrier of the future. Its potential uses are diverse and continue to grow. In industries, hydrogen plays a crucial role in processes such as steelmaking, as well as in the chemical and glass sectors. It is also gaining momentum in mobility as a clean fuel for fuel cell vehicles and can be used to generate electricity through fuel cells. The downside of the energy carrier is that it is a colourless and odourless gas that is also flammable. Appropriate safety measures and safe monitoring systems are required during production and handling.

Appropriate safety measures and reliable monitoring systems are therefore essential during the production and handling of hydrogen. What is becoming increasingly clear is that public acceptance of new technologies is closely tied to how well-associated risks are managed, and potential errors are addressed. Even in these emerging application areas, it is extremely valuable to use the experience gained from over 40 years of functional safety in the industry. With its automation solutions, Pilz ensures that hydrogen can be used safely and efficiently across the entire value chain of this energy carrier: from H₂ production in electrolysers to storage and transport, all the way to its use in fuel cells or industrial burners.

Safe, efficient storage and transportation

For transportation, hydrogen is highly compressed and carried in special high-pressure tanks by rail, water, or road. However, rapid pressure changes, such as those that occur during the filling or emptying of hydrogen or even due to temperature fluctuations, can place repeated stress on the composite transport containers. This can lead to delamination (where the material’s layers separate), reduced service life of the pressure vessel, leakages, and, in the worst case, explosions.

To protect both the hydrogen tanks and people near transfer points, special safety precautions are essential during the filling and emptying processes. Pilz’s proven, safe controllers reliably monitor these transfer operations using failsafe analogue value processing and can automatically halt the process if an error occurs.

In Bremerhaven, Germany, energy company GP JOULE relies on Pilz’s safety solutions. GP JOULE converts surplus wind energy into CO₂-neutral hydrogen, stores it in tanks mounted on specialised truck trailers, and delivers the highly flammable gas to hydrogen refuelling stations in the city. Among others, buses operated by Bremerhaven Bus are refuelled with this green energy. Thanks to Pilz, the loading and unloading of these pressure vessels is not only simple and quick—but most importantly, safe—at all transfer points.

Safety-related accuracy: measured values accurate to within 1 %

The process values that are critical for hydrogen (H₂) refuelling or storage are recorded using safe analogue sensors and read by a safety controller. When monitoring pressure levels between 0 and 1,000 bar, it’s essential to maintain safety accuracy throughout the entire monitoring system. Risk assessments for tube trailer refuelling have shown that even a 1% accuracy (which equals 10 bars in this case) can meet safety standards.

In practice, the specification of the analogue signal is often considered sufficient. This may seem acceptable based on the datasheet, but it doesn’t automatically make it suitable for use in safety-related designs. It’s important to take a closer look.

After the process values are captured, it is essential to ensure that the absolute (static) limit values are not exceeded and to detect any dynamic changes as needed. This calls for more advanced monitoring functions, such as safe gradient monitoring. The “Safe Ramp Monitoring” software block checks whether pressure and temperature changes are happening within the safe rise and fall limits, as well as the speed at which hydrogen is being filled or emptied. If these values exceed the safe range, the safety controller responds – for example, by slowing down a regulator or compressor or by completely closing a valve.

A holistic approach to safety and security

Automation solutions can support the traditional mechanical safety features of components used in the hydrogen industry. This is important because functional safety always looks at how safely a process responds throughout its entire lifecycle.

Operational Technology (OT) security helps protect the availability of plants and machines from tampering and misuse. The main focus is on safeguarding plant data and knowing who has access to the process. These functions are especially important for critical infrastructure facilities.

Pilz strongly believes that taking an early and holistic approach to both safety and security in the hydrogen industry ensures complete protection. The growing hydrogen sector can benefit from many years of experience in this area.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

A user operates a network of IoT-enabled machines across factory floors to monitor and control production lines. As these devices are distributed across various locations, manual updates and maintenance become time-consuming and costly. Regular deployment of BSP (firmware) updates and software patches is crucial for addressing security vulnerabilities, enhancing functionality, and improving machine performance—ensuring optimal efficiency and reliability.

Solutions with Corvina Edge Manager

Leveraging the Over-the-Air (OTA) capabilities of Corvina Edge Manager, users can efficiently oversee and update all its IoT Edge devices from a single, centralised platform. The procedure includes the following step.

Remote device monitoring & diagnostics: The company can track the version of each software and firmware installed on Edge in real-time through Corvina’s Edge Manager dashboard, which provides easy identification of devices that need updates or maintenance.

Over-the-Air updates: Instead of sending technicians to update each device physically, the Corvina CEM OTA system enables users to securely deploy firmware and software updates to all devices across the factory floor with just a single mouse click. Updates can be run immediately or scheduled during off-peak hours to minimise disruptions to production.

Corvina Edge Management streamlines the update process, ensuring devices across the factory stay current, secure, and efficient without disrupting production.

Automatic and secure deployments: Corvina ensures the OTA updates are encrypted and authenticated, maintaining the integrity of the updates. Additionally, rollback features enable the company to revert to previous versions in the event of any issues.

Scalability: With thousands of IoT Edge devices in use, the OTA system supports bulk updates, ensuring all devices, regardless of location, stay up-to-date with the latest firmware and software without requiring manual intervention.

The following procedure reduces operational downtime due to faster and more efficient updates. It minimises the need for on-site maintenance, saves costs on travel and labour, enhances security with the latest patches deployed automatically, and increases the device’s longevity and performance through regular updates.

The X Platform world

The X Platform exists to bridge the gap between the aspirations of machine builders and the realworld needs of factory owners in the industrial automation sector. The platform serves as a comprehensive toolbox, helping users address current challenges while preparing for future ones.

The X Platform is a partnership, not merely a partnership. It empowers users to tailor solutions to the specific challenge at hand, ensuring they remain at the forefront of industrial innovation. The goal is to give machine builders the freedom to focus on what they do best: creating outstanding machines that meet the needs of factory owners.

Need of the hour-

Edge Security – Helps protect your data and business.

Remote access & VPN – Simplifying system integration, providing users with the ability to monitor and adjust processes anywhere.

Edge management – Making updates remotely, thus saving time and resources.

Tomorrow’s Want-

Remote and condition monitoring – Giving users the tools for proactive diagnostics.

OEE & Energy Efficiency – Monitoring and managing resources for sustainable growth.

Performance consultancy – Offering insights into optimising machinery’s potential.

Future Vision-

Marketplace integration – Creating potential channels for resource and information exchange.

Virtual Logic Control – Preparing for the Possibilities of AI-Driven Process Enhancements.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Schmalz Jumbo vacuum lifters are helping internal logistics in India by reducing physical strain and improving worker safety across industries through smart, ergonomic, and reliable lifting solutions.

The relentless pace of internal logistics in India—from busy manufacturing hubs to expansive distribution centers—often conceals a silent struggle. Operators continuously contend with the repetitive and physically demanding task of manually handling a wide variety of goods: heavy sacks of raw materials, bulky cardboard boxes, slippery barrels, and awkward buckets and jugs. This ongoing strain is beyond an operational inefficiency; it’s a serious concern for worker health and safety. The impact is far-reaching, from chronic back pain and increased injury rates to a fatigued workforce operating below capacity. These issues disrupt workflows, create bottlenecks, and ultimately affect the bottom line.

Fortunately, a powerful solution is emerging to break this back-breaking cycle: the Schmalz Jumbo series of vacuum tube lifters. These intelligent, ergonomically designed lifting devices are transforming internal logistics processes across India and globally, offering a safer, faster, and more efficient method for handling a wide range of goods. Using advanced vacuum technology, Schmalz Jumbo lifters eliminate the physical strain of manual lifting, resulting in improved operator safety and a noticeable increase in productivity.

Schmalz, fully aware of the challenges and growing demands of the Indian logistics sector, delivers these innovative solutions nationwide. By understanding local needs, the team provides expert consultation, professional installation, and responsive after-sales service, ensuring the smooth integration of Jumbo lifters into existing workflows. By partnering with Indian businesses, Schmalz India contributes to a safer and more efficient material-handling environment, helping companies enhance their internal logistics while prioritising worker well-being. This strong local presence ensures that Indian industries can easily access and benefit from Schmalz’s cutting-edge technology.

The Schmalz Jumbo series includes several models, each designed to meet specific lifting needs. Among the most widely used are the JumboFlex, the JumboSprint, and its specialised variant, the JumboSprintEX, for hazardous areas.

The JumboFlex is a versatile, ergonomic solution for frequently handling lighter items weighing up to 50 kg. Its standout feature is its one-hand operation, using an intuitive two-button control that allows the operator to lift, lower, and release loads with precision—even suspending them at any desired height. The comfortable handle design reduces strain and allows for extended use without fatigue. Businesses benefit from faster handling and improved ergonomics, particularly in operations such as order picking and machine loading. The quick-change system enables the use of different vacuum grippers, making the JumboFlex highly adaptable. Optional features, such as a swivel mechanism for horizontal rotation, further enhance its flexibility and help reduce product damage during handling.

JumboSprint – Heavy-Duty performance

For heavier, more demanding tasks, the JumboSprint stands out. It is ideal for frequent handling of compact loads up to 300 kg. The bow-shaped operator handle surrounds the unit, offering excellent force transfer and control when lifting items such as bags, barrels, or rubber bales. Lifting and lowering are controlled by simply pulling up or pushing down on the handle lever, making it easy for a single operator to manage large loads. The modular system includes a wide range of grippers and accessories, along with an optional rotation unit for precise positioning. The JumboSprint also carries the AGR (Aktion Gesunder Rücken e.V.) seal of approval, recognising its role in reducing work-related musculoskeletal issues and improving operator motivation.

JumboSprint EX – Safety in hazardous environments

Addressing safety in potentially explosive settings, the JumboSprint EX is a specialised model designed for use in ATEX zones 1/21 and 2/22. It can handle up to 250 kg in Zone 2/22 and 85 kg in Zone 1/21, offering safe lifting for industries such as chemical processing or paint manufacturing. Like the standard JumboSprint, it features a fully enclosed operator handle for precise control. The system is available as a complete unit, including a vacuum tube lifter and an explosion-protected steel jib crane—making it easier to implement and fully compliant with stringent safety standards. It helps ensure operator protection and uninterrupted, safe operations in sensitive areas.

By adopting Schmalz Jumbo vacuum tube lifters, supported by the expertise of Schmalz India, businesses can directly address the challenges of manual lifting. Workers experience a significant reduction in physical strain, resulting in improved comfort, fewer injuries, and increased job satisfaction. For companies, this results in faster cycle times, improved material flow, and a healthier, more productive workforce. The investment in Schmalz Jumbo will secure the long-term health of users while driving sustainable efficiency across operations in India and beyond.

Contact for questions

Schmalz India Private Limited

Marketing Department

EL 38, J Block, MIDC, Bhosari, Pune 411026

T: 020-69115500

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

The circular water economy model promotes long-term sustainability by minimising waste, conserving resources, and increasing system efficiency. It is a pathway to reduce dependence on freshwater and build resilience against climate change and operational disruptions. Dharmendra Pratap Singh, Chief Operating Officer of Infrastructure Solutions at UMPESL, emphasises the importance of a circular water economy in India.

Water scarcity is a pressing environmental and economic issue, especially in India, where over 1.4 billion people depend on just 4% of the world’s freshwater resources. As the Indian wastewater treatment market surges, there is an opportunity to shift from linear consumption patterns to a circular water economy, where wastewater is viewed as a renewable asset. India holds the fifth-largest wastewater treatment market globally, underscoring its potential for innovation and leadership in this sector.

The future holds an opportunity to reimagine wastewater as a resource rather than a burden. The idea of a circular water economy is gaining momentum, promising to revolutionise how water is sourced, used, treated, and reused—especially across industries. A circular water economy centres on closing the loop, where water is continually reused through treatment, recycling, and reclamation. Unlike the traditional linear approach of extract-use discharge, the circular model promotes long-term sustainability by minimising waste, conserving resources, and increasing system efficiency.

This concept is particularly relevant in India, where erratic rainfall, over-exploited groundwater, and polluted water bodies have compounded the crisis. The circular model offers a pathway to reduce dependence on freshwater and build resilience against climate change and operational disruptions.

Voltas, with its wholly owned subsidiary, Universal MEP Projects & Engineering Services Limited (UMPESL), is enhancing India’s water security by advancing treatment, recycling, and responsible consumption practices.

Although progress has been made through water audits and conservation initiatives, the transition towards full circularity remains uneven. Forward-thinking companies are taking a proactive approach, re-engineering their supply chains to integrate water-efficient technologies, ensure sustainable sourcing, and enforce wastewater reuse standards across their vendor ecosystems.

Here are several practical and impactful strategies that companies can implement to reduce water risks and contribute to a sustainable future:

Sustainable water sourcing

The first step in water stewardship is understanding where and how water is drawn. Businesses must prioritise sourcing from sustainable and low-impact water sources, be it rainwater harvesting, groundwater recharge systems, or municipal recycled water. Conducting Water Risk Assessments (WRA) across the supply chain can help identify hotspots and take preemptive action before a crisis strikes.

Water-efficient manufacturing

The intervention of reducing water consumption at the process level remains a crucial step. Adopting closed-loop water systems, investing in water-efficient technologies, and retrofitting existing systems with smart meters and low-flow fixtures can significantly curb usage. In textiles, chemicals, and food processing sectors where water use is intensive, this can lead to conservation with cost savings.

Wastewater recovery and reuse

A linchpin of the circular water economy is wastewater reuse. Treating greywater and blackwater to a standard suitable for reuse, whether in irrigation, cooling, flushing, or even in processes, is no longer a futuristic concept but an achievable goal. Zero Liquid Discharge (ZLD) systems are becoming increasingly viable with advances in membrane bioreactor (MBR) and reverse osmosis (RO) technologies.

Community water partnerships

Beyond internal efficiency, companies can drive impact by supporting local water projects. Whether it is rejuvenating ponds, constructing check dams, or improving access to sanitation, engaging with communities fosters goodwill while contributing to regional water security.

Digital Water Management

Digitalisation offers a transformative pathway for water efficiency. Smart water grids, IoT-based sensors, real-time monitoring, and AI-powered analytics can enable predictive maintenance, leak detection, and usage optimisation. This visibility empowers companies to make data-driven decisions, enhancing accountability and performance.

Employee and community engagement

Promoting water literacy among employees, suppliers, and surrounding communities fosters a culture of conservation. Internal campaigns, community awareness drives, and school education initiatives can build lasting behavioural changes.

Government initiatives, including the Jal Jeevan Mission, Atal Mission for Rejuvenation and Urban Transformation (AMRUT), and Namami Gange, are bolstering infrastructure for water access and quality. There is increasing encouragement for industries to install ETPs, adopt ZLD, and engage in water credits and trading mechanisms. The State Water and Sanitation Missions (SWSMs) are collaborating with public and private stakeholders to provide drinking water and sanitation services to rural and semi-urban populations. This expanding ecosystem will be fertile ground for public-private collaboration and technology deployment.

UMPESL has engaged in initiatives that reflect the circular water ethos. Treated drinking water is now reaching several villages through rural water supply projects commissioned in Ayodhya and Deoria under the State Water & Sanitation Mission. Similarly, internal facilities are adopting measures like zero-liquid discharge, wastewater recycling for horticulture, and partnerships for common effluent treatment in industrial estates.

Voltas has partnered with the Tata Group’s Project Aalingana, aiming to achieve net zero by 2045 and become water-neutral by 2030. Their Waghodia factory is equipped with a Zero Liquid Discharge (ZLD) system, ensuring that not a single drop of wastewater goes unutilised. Meanwhile, in Pantnagar, operations are integrated with a common Effluent Treatment Plant (ETP), demonstrating efficient collective water management.

India’s progress towards a water-secure future depends on the swift adoption of the circular model by industries. Turning wastewater into a sustainable resource is a practical, scalable, and essential approach to managing our most precious resource. Businesses must move from intention to action—embedding water circularity into their core strategy, operations, and culture. By doing so, they will future-proof their growth and contribute to a broader ecological and social transformation.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Thriam Toolroom combines all plastic product manufacturing expertise under one roof, offering a synergistic model that streamlines the entire product realisation process. Toolroom’s state-of-the-art facility ensures that production can commence without unnecessary pauses.

In-house moulding in plastic component manufacturing

When you are dealing with product development, every single day saved can give you a competitive edge. For businesses in the world of plastic components, the journey from an initial concept to a finished, the marketable product often involves two distinctly linked stages: the creation of a precision mould and the subsequent moulding of parts. Traditionally, these tasks are handled by separate entities – a dedicated toolroom and an independent moulding facility. While this fragmented approach may seem like a standard, it often introduces hidden delays, communication breakdowns, and logistical nightmares that can severely impact project timelines.

Forward-thinking companies recognise the profound time-saving benefits of partnering with an integrated toolroom that also boasts in-house moulding capabilities. This synergistic model streamlines the entire product realisation process, offering an unparalleled path from design to mass production. Thriam Toolroom is a prime example of how combining all plastic product manufacturing expertise under one roof delivers undeniable advantages.

One of the most immediate and impactful time-savers is streamlined communication and unparalleled collaboration. When mould designers, toolmakers, and moulding engineers operate within the same facility, traditional communication barriers vanish. The structure of Thriam Toolroom ensures that all stakeholders are on the same floor. This proximity facilitates real-time discussions, instantaneous feedback loops, and rapid problem-solving. Misinterpretations that could cost days or even weeks in a fragmented system are swiftly addressed, ensuring that the mould design is perfectly aligned with manufacturing requirements from the outset.

This integration accelerates the prototyping and iterative development process. Once a mould is crafted by the toolroom, it doesn’t need to be packaged, shipped, and scheduled for trials at a separate facility. Instead, it can be moved directly to an adjacent moulding machine for immediate testing. This capability is where they shine. Their comprehensive 15-step mould manufacturing process, coupled with immediate access to their moulding capabilities, allows for swift first-shot evaluation. If there are any design flaws, moulding problems, filling issues, or cooling inefficiencies, the mould can be quickly sent back to the toolroom for fixes. This rapid iteration cycle compresses development timelines, preventing the costly and time-consuming back-and-forth typical of outsourced scenarios.

Furthermore, an integrated facility provides superior quality control and reduced risk. The toolroom can immediately assess the performance of newly built moulds by producing actual parts. This enables real-time validation of part quality, dimensional accuracy, and overall moulding process integrity. Since Thriam Toolroom is equipped with advanced CMM (Coordinate Measuring Machine) capabilities and rigorous quality checks at every step, it can make precise adjustments to the mould on the spot, guaranteeing that it consistently produces high-quality parts right from the first production run.

The elimination of logistical complexities and associated downtime is a significant time-saver. By having capabilities in-house, businesses bypass all transportation time, costs, and the inherent risks of damage during transit. The seamless transition from mould completion to initial moulding trials means less idle time for the project. Their state-of-the-art facility is designed for this operational efficiency, ensuring that once the tool is perfected, production can commence without unnecessary pauses.

Opting for a toolroom with an integrated moulding facility is a strategic decision that directly translates into substantial time savings throughout the product development lifecycle. Toolroom exemplifies this advantage, offering mould manufacturing, compression moulding, injection moulding and 3D printing under one roof.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Fronius constantly endeavours to optimise the dosing of shielding gas. After all, too much or too little gas impairs the quality of the result. Shielding gas is also a valuable resource due to its cost, and producing it is energy-intensive. With such a large carbon footprint, shielding gas should be used sparingly. The intelligent gas controller from Fronius optimises consumption while maintaining consistently high welding quality and helps to cut gas usage by up to 40 percent.

Whether argon, helium, or mixed gases, shielding gas is essential for a stable arc and perfect welding results. Too little gas does not provide sufficient protection, allowing ambient air to penetrate the welding point. The consequences are oxidation and porosity of the weld seams, increased spatter, and an unstable arc. Too much shielding gas is a waste of resources and also leads to problems. Excessive gas flow causes turbulence, which impairs the gas shield and also leads to air admixtures. With the negative effects here being similar to those of an insufficient gas feed, how do you reconcile the demands of quality, cost, and resource efficiency?

Reducing gas costs = saving resources

A controlled gas setting for the respective welding process, material, or welding position ensures good weld quality and reduces costs. “Our intelligent gas controller ensures that the arc and the weld pool are perfectly protected while making it possible to reduce gas consumption in two ways significantly,” explains Philipp Schlor, Strategic Product Manager at Fronius International. “Firstly, it eliminates the so-called ‘blow out’ with every welding start. On the other hand, it allows the shielding gas quantity to be regulated according to output or precisely set in advance for each welding job. Our experience shows gas savings of up to 40 percent can be achieved. For some customers, this value is even significantly higher if many short seams are welded, for example. In addition, consuming fewer resources lowers the carbon footprint of the manufactured components and the company as a whole: a factor that is becoming increasingly important and increases competitiveness.

Perfect shielding gas environment for every welding start

Every welding start—whether for tacking or seams of any length—begins with a gas shroud forming before the arc is ignited to protect it from the atmospheric air. However, when welding starts, the set flow rate that should be available for welding is briefly exceeded. The Fronius gas regulator smooths this ‘blow out’ and ensures no gas is wasted.

A comparison between a conventional gas solenoid valve and an intelligent gas controller illustrates the difference. If, for example, a gas flow of 18 l/min is required, the Fronius gas controller builds this up immediately and keeps it constant. With a gas solenoid valve, on the other hand, the gas flow increases for a short time up to 55 l/min and then regulates itself back down to the set, actually required quantity. The difference in consumption is evident at every welding start—and the more frequent and shorter the seams, the greater the savings.

Optimal gas control for each welding job

Standard gas solenoid valves switch the set gas flow on and off after the gas pressure regulator. The flow rate is defined for each component, with one value for every weld. In practice, this means that the gas flow rate corresponding to the gas requirement of the weld seam that requires the highest gas flow is set for the entire component. In other words, if 15 different seams need to be welded on the same component, one of these welds is constrained. This job defines the minimum flow rate value for all other seams—even if the remaining 14 welds could be produced to the required quality with less gas. To counteract this waste, the high-tech Fronius TPS/i and iWave welding solutions have an intelligent gas controller to regulate the gas flow depending on the output or allow individual gas dosing for each job.

Calculate and benefit from immediate gas savings

All Fronius TPS/i and iWave welding solutions can be retrofitted with an intelligent Fronius gas controller. The corresponding installation option can be fitted in simple steps, leaving nothing between you and gas-optimised welding.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Indra teams up with AXISCADES to produce defence systems in India, boosting local manufacturing under the Make in India initiative.

Indra, a Spanish defence and technology company, has formed a strategic alliance with Indian engineering and technology firm AXISCADES to co-develop and manufacture cutting-edge aerospace and defence equipment in India.

The MoU was signed during the Paris Air Show at Le Bourget by Indra CEO José Vicente de los Mozos, AXISCADES Chairman Dr. Sampath Ravinarayanan, Indra Chairman Angel Escribano, and AXISCADES CEO Alfonso Martínez.

As part of this agreement, AXISCADES will oversee the local production of several defence solutions developed by Indra. These include antennas for Tactical Air Navigation devices (TACAN), Distance Measuring Equipment (DME), which provides aircraft with critical in-flight data, and countermeasure devices, such as MANPADS (Man-Portable Air-Defence Systems).

The agreement allows Indra to leverage AXISCADES’ design, development, and manufacturing capabilities in India, resulting in more efficient and agile solution delivery. Furthermore, both firms intend to co-develop new goods by adapting Indra’s existing technology or creating new solutions to serve both domestic and international markets.

This collaboration deepens Indra’s worldwide industrial ecosystem and broadens its long-standing position in India, where it has been a key provider of systems for the Indian Armed Forces and civil aviation modernisation projects, such as air traffic control.

Looking ahead, the two businesses want to work together further on Maritime Patrol Aircraft Airborne Solutions and strategic defence programmes with the Defence Research and Development Organisation (DRDO). Combat aircraft systems, medium-range maritime reconnaissance, and multi-mission maritime aircraft are among the topics being discussed.

This agreement is consistent with the ‘Make in India’ strategy, reaffirming India’s resolve to strengthen its defence industrial base, stimulate knowledge transfer, and promote innovation through trusted global collaborations.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Daimler Truck has opened a new plant in Indonesia to assemble Mercedes-Benz trucks and buses, boosting local production and regional presence.

Daimler Truck has established a new greenfield manufacturing site in Cikarang, Indonesia, known as Daimler Commercial Vehicles Manufacturing Indonesia (DCVMI). The 15-hectare plant has an annual production capacity of 5,000 Mercedes-Benz trucks and buses and is an important part of Daimler Truck’s regional expansion plan. It will act as a vehicle assembly and distribution base for important Southeast Asian markets.

Daimler India Commercial Vehicles (DICV), headquartered in Chennai, will provide high-quality Completely Knocked Down (CKD) kits to support the plant. This phase aligns with Daimler Truck’s “Bigger and Better” goal, which aims to improve customer solution agility, workflow, and resilience. The collaboration brings together Daimler’s global technologies and local Indonesian knowledge.

Satyakam Arya, Managing Director and CEO of Daimler India Commercial Vehicles, stated, “As DICV becomes more integrated into Daimler Trucks’ global manufacturing network, we will play an important role in building capabilities in Indonesia—transferring knowledge, developing talent, and strengthening the regional ecosystem.”

The plant will continue to produce Mercedes-Benz flagship vehicles such as the Axor truck and bus chassis, which include the 2528 CH, 4928 T, 4028 T, 4023 T, 2528 RMC, 2528 CX, and 2528 C.

Sankaranarayanan Ramamurthi, President Director of DCVMI, commented, “This plant is more than just an addition to our infrastructure; it is a manifestation of our vision to make a tangible contribution to Indonesia’s economy, empower local communities, and build a stronger industrial ecosystem.” Each unit manufactured here symbolises not only engineering brilliance but also a spirit of collaboration and our belief in Indonesia’s future.”

The Cikarang facility has manufacturing systems that are in line with Mercedes-Benz’s global standards. The plant, which includes a test track and a sophisticated paint booth, increases manufacturing efficiency and flexibility and improves Daimler Truck’s footprint and innovation capabilities in Asia.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.