Klüber Lubrication India offers advanced speciality lubricants tailored for electric vehicles, addressing unique NVH, wear, and performance challenges.

With electric and hybrid vehicles becoming more mainstream and autonomous vehicles awaiting a grand roll-out, the automotive industry has been under considerable pressure from governments and society to pursue a more sustainable growth model. Klüber Lubrication India understands that this transition also brings with it demanding consumer expectations on ride comfort and safety standards. So, in cooperation with various partners from science and industry, Klüber has developed innovative speciality lubricants to bring new solutions to the market that would make electric mobility highly efficient.

Lubrication challenges in electric vehicles

As the automotive industry moves towards electric vehicles to address the need for cleaner mobility, it faces a new set of lubrication requirements different from traditional ICE vehicles. OEMS developing parts and assemblies for EVS in the two-wheeler/three-wheeler and passenger vehicle segment are extremely particular about curbing unwanted noise, vibration, electric erosion, and other similar challenges. This host of issues cannot be tackled using traditional lubricants.

Klüber Lubrication – Helping put new mobility solutions on the fast track

Klüber speciality lubricants are made with high-quality raw materials and special additives that are dynamically light with low friction properties, making them the most suitable option for the industry. Several components in EVs are made from plastics like POM / PAM / PA6 or Delrin to reduce weight. Klüber Lubrication ensures that its EV lubricants are compatible with the polymers mentioned above.

Although many standard applications remain the same in ICE and EV vehicles, several moving parts have become redundant in EVs. These include the powertrain, propeller shaft, starter motor, and water pump, among others, thus making noise and vibration control one of the most challenging issues faced by EV OEMs. Similarly, the brake judder and squeal, suspension, and steering ride comfort also require high-performance lubricants to avoid the issues above. Klüber speciality lubricants are specifically designed to overcome such NVH issues, having proven industry experience to meet these stringent requirements.

Also, with the development of EVs, it is visible that a few unconventional applications like charging gun actuators, throttle positioning sensors, and combi brake systems, among others, where traditional lubricants cannot fulfil OEM requirements. Klüber India is currently working with OEMs and their Tier 1 suppliers to understand these requirements, suggest suitable lubricants from our products, and initiate new developments if needed.

A few of the application references and their consequent development processes are outlined below:

Why choose Klüber for e-Mobility?

Klüber Lubrication offers an extensive portfolio of efficient solutions tailored to meet the most challenging requirements. The existing lubricants are constantly evolving, particularly in terms of temperature, long-term stability, higher loads, and increasingly stringent efficiency requirements. When creating custom solutions, Klüber Lubrication draws on decades of proven and practical experience in the automotive industry.

Global Contact:

Sudha. P

Senior Executive – Business Support

Toll-Free Number: 18001237686

Fax: +91 8066901201

Phone: +91 8066901200

Email: marketing@in.klueber.com

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

ZF India has signed a deal to supply locally made manual and automatic transmissions for heavy-duty trucks, supporting the Make in India initiative.

ZF India has entered into a significant relationship with a renowned Indian commercial vehicle manufacturer to supply several thousand manual and automatic transmissions for heavy-duty trucks. The contract, which was finalised in March 2025, includes 9-speed gearboxes suited for vehicles with more than 300 horsepower.

The agreement covers ZF’s EcoMid manual and EcoTronic Mid automatic transmissions, which are designed for trucks weighing more than 25 tonnes and running in the 1300 Nm torque class. These systems will be manufactured at ZF’s Chakan site in Pune, contributing to the “Make in India” initiative.

ZF has a strong presence in India’s high-torque gearbox industry, with 9-speed systems capable of handling up to 1500 Nm and 12-speed variants rated at 3200 Nm. The EcoMid series is appropriate for vehicles with gross weights of up to 55 tonnes and includes both direct drive and overdrive options.

ZF emphasises the advantages of these transmissions, such as increased fuel efficiency, fewer driver strains, and longer clutch lives. The items are part of ZF’s modular platform approach to commercial vehicle solutions.

President of ZF Group India, Akash Passey, highlighted the company’s six-decade history in the nation and its ongoing dedication to operational efficiency. Senior Vice President P. Kaniappan stated that these technologies are critical for improving performance in India’s heavy-duty commercial vehicle industry.

Globally, ZF Group is a leading technology supplier in the automotive and industrial sectors. In 2024, the company had sales of €41.4 billion and employed over 161,600 people across 161 industrial facilities in 30 countries. In India, ZF continues to develop technology for commercial cars that are autonomous, networked, and electrified.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Murata Machinery, Ltd. (Muratec) offers MT100, a high-performance multi-tasking CNC machine designed for seamless turning and milling in a single setup. With dual spindles, up to three turrets, Y-axis capability, and full automation options, the MT100 is ideal for complex components across automotive, aerospace, medical, and precision engineering industries.

MT100 is an ultimate multi-tasker with two opposed in-line spindles. It features both turning and milling capabilities, all combined in one machine. The machine can be configured with 2 or 3 Turrets, each with 15 stations and can house up to 45 stations. It has a “Y” axis on all Turrets and a Live Tool function on all stations. This offers flexible automation with bar work and chuck capabilities. Both spindles can operate simultaneously, and two turrets (two tools) can be used in a single chucking.

The programmer can utilise various cutting variations, allowing for the use of 2 turrets or 3 turrets with the Y-axis for the optimal cutting process in simultaneous turning and milling. MT100 provides process integration to complete the work in a single setup. Small and large workpieces up to 150 mm can be accommodated.

A large-sized bar feeder, capable of handling bars up to 65mm in diameter, is available as an option, along with a part catcher. This setup enables the automatic unloading of parts up to 65mm in diameter, allowing the machine to operate in a fully automated mode without requiring human intervention for part loading and unloading. Spindle drive motors of 7.5kW, 11kW, and optionally 15kW are available. A high-speed 3-axis CNC Gantry Loader is also available as an option, providing an added advantage for uninterrupted production. The loader is capable of handling heavier parts efficiently.

Suitable applications vary from automotive to non-automotive and cover hydraulics, pneumatics, aerospace, medical, oil and gas, precision engineering, die and moulds, etc. Some typical components include a shaft, AC compressor cylinder block, parts for CNG fittings, the differential case, etc.

Contact:

Meiban Engineering Technologies Pvt. Ltd., No. 38, 7th Main, J C Industrial Estate, Yelachenahalli, Kanakapura Road, Bangalore – 560 111.

Tel: +91-80-2686 0600 | Email: office@meibanengg.com

Visit Murata Machinery at ACMEE 2025, Hall B, Stall No. B78 from 19 – 23 June 2025 at Chennai Trade Centre

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

PMI’s advanced linear motion components help manufacturers improve their performance by delivering high precision and strong load capacity.

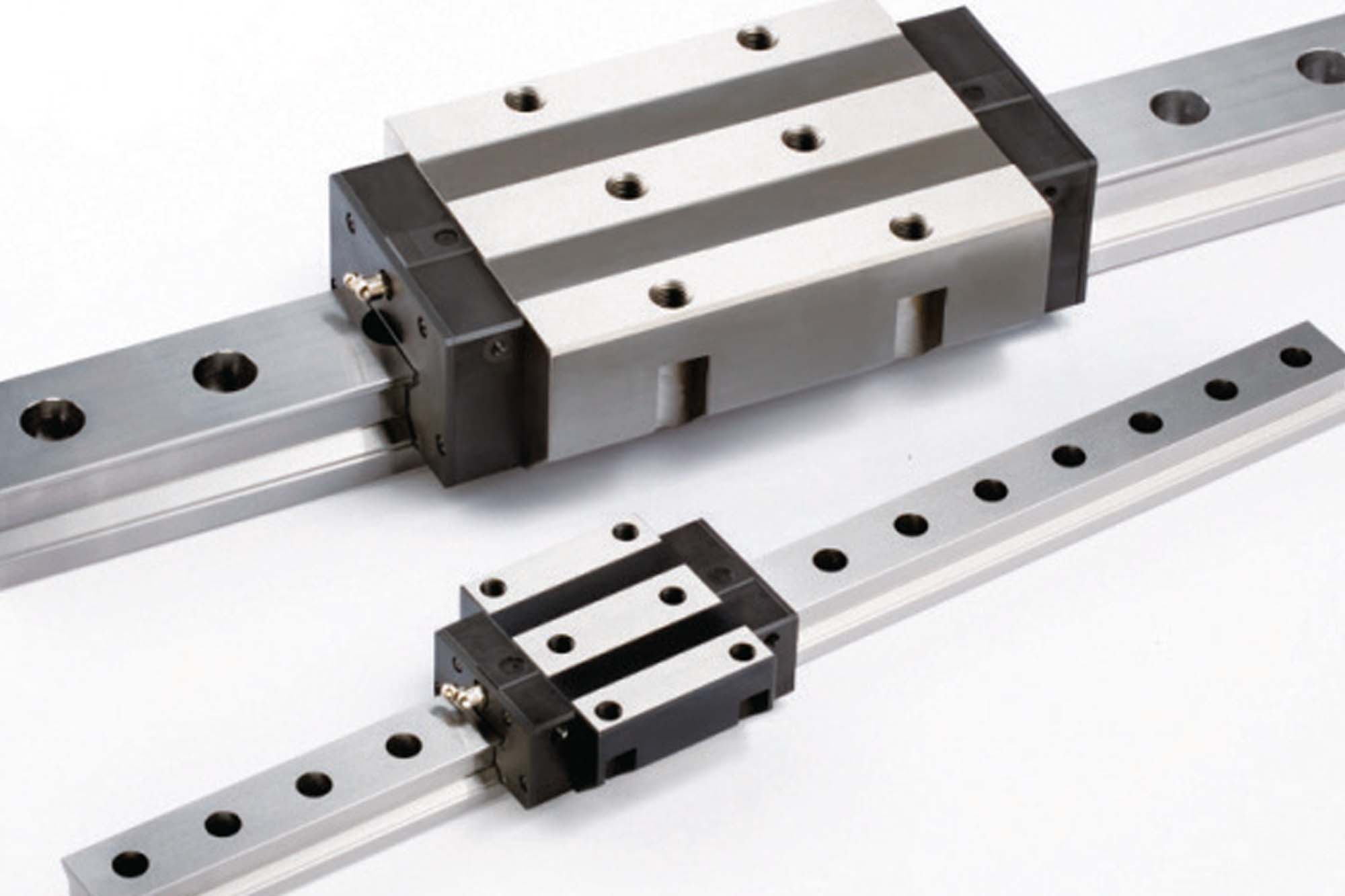

Roller guideways

PMI roller guideways comprise a rail with built-in rollers and a carriage that glides smoothly along the rail with minimal friction. The rollers are designed to distribute the load evenly, ensuring stable and precise motion even under heavy loads. They have high loadcarrying capacity. The design of the rollers and the raceways allows for the distribution of loads over a larger contact area, making them suitable for applications that require the movement of heavy loads with high precision.

PMI roller guideways are also known for their rigidity and stability. The design of the rollers and the rail structure provides increased stiffness, reducing vibration and ensuring consistent positioning accuracy in high-speed or high-load applications.

PMI roller guideways are a popular choice in machine tools, automation, semiconductor manufacturing, and more, where precise linear motion control is essential. Their robust construction, high load capacity, rigidity, and smooth operation make them a reliable solution for demanding applications that require efficient and accurate linear motion control. PMI ground ballscrews are precision mechanical devices used in machinery and automation systems.

Ground ballscrew

Ground ballscrew convert rotary motion into linear motion with high efficiency and accuracy. Ballscrews are designed with precision-ground threads to ensure smooth operation, low friction, and excellent positioning accuracy.

A key feature of PMI ground ball screws is their exceptional precision. The threads on the ballscrew shaft are meticulously ground to tight tolerances, ensuring smooth motion and consistent positioning accuracy. This high level of precision is essential for applications requiring fine control and repeatability, such as CNC machines, industrial robots, and semiconductor manufacturing equipment.

PMI ground ballscrews also offer high efficiency due to their low-friction design. The use of precision-ground ball bearings between the screw shaft and the nut reduces friction, resulting in smoother operation and energy savings. This efficiency is essential for applications that demand high-speed and high-precision linear motion.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

CLOOS INDIA delivers a full range of robotic and manual welding solutions from a single source. They have been offering individual automation solutions for a wide range of industries, including construction and earthmoving, agriculture, mining, materials handling, hydraulic cylinders, transformers, and shipbuilding.

QINEO-Manual welding solution

Cloos India offers high-quality welding machines for manual and automated applications. The next-generation MIG/MAG welding power source is an excellent new technology for pulsed arc welding.

ArcBoT- Cobot welding solution

With the QINEO ArcBoT Welding System, users can weld small batch sizes economically and with high quality. The high-tech MIG/MAG welding power source and the precise ArcBoT work perfectly together.

The compact “Ready to weld” package is delivered completely ready for operation. This guarantees a problem-free integration into existing production processes. A torque sensor in each axis allows the ArcBoT to be programmed and moved precisely.

QIROX- Robotic welding solution

QIROX comprises all solutions for automated welding and cutting. Due to its modular design, the QIROX system allows scalable solutions to match production requirements. The QIROX system, which encompasses automatic welding and cutting robot technology, positioners, safety technology, software, sensors, and interfaces to process technology, is complemented by an extensive range of options and complementary services.

Inauguration

CLOOS INDIA opened a new facility in Chinchwad, Pune, on April 10th 2025, combining sales, service, design, R&D, training, experience centre, and stores under one roof, aiming to improve operational excellence and provide superior service and support to customers. This milestone reflects CLOOS INDIA’s commitment to advancing technology, strengthening customer relationships, and supporting the dynamic needs of the Indian manufacturing sector.

All from a single source

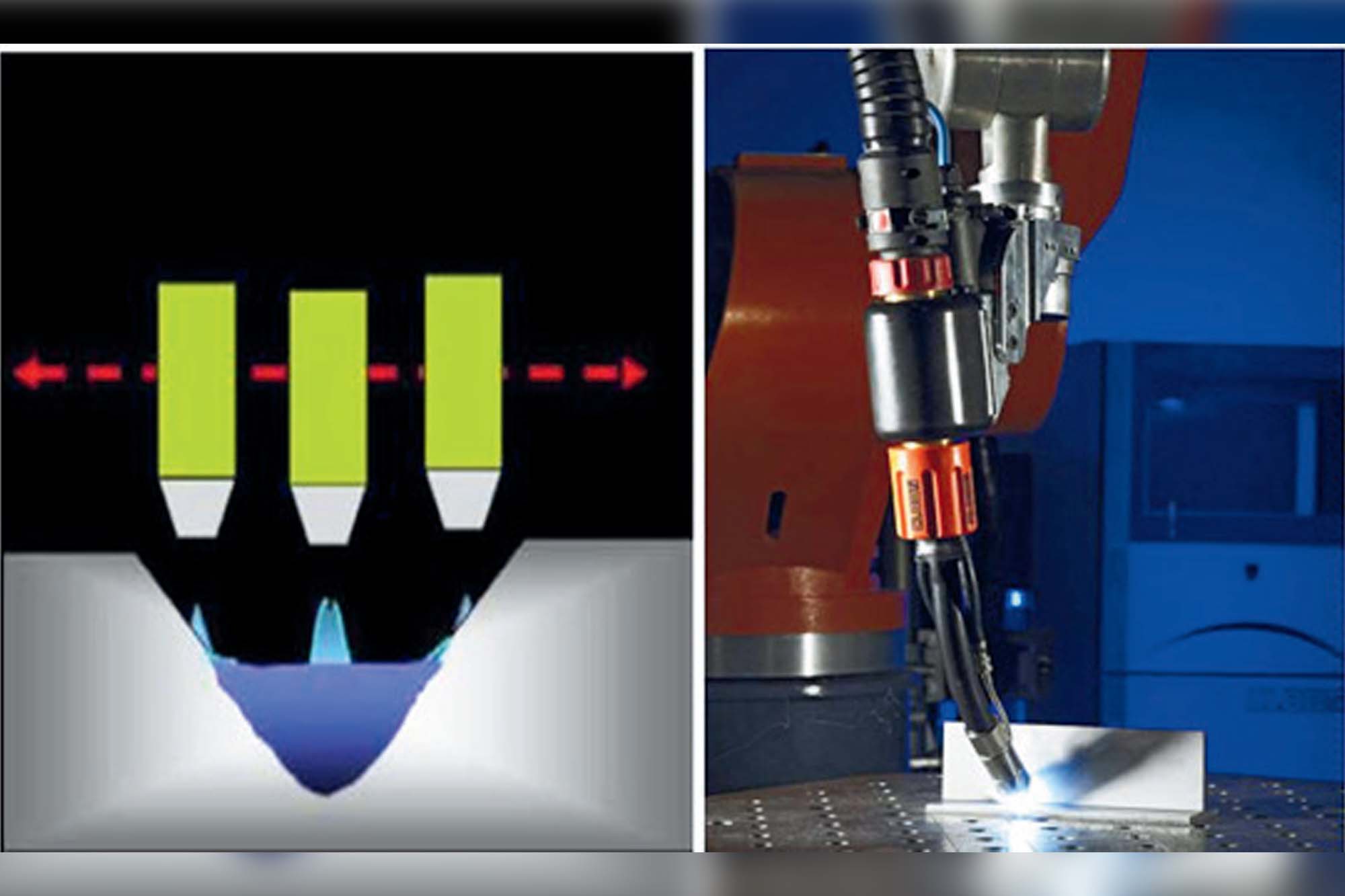

CLOOS Arc Seam Tracking without a laser ensures precise torch position monitoring of the programmed path during welding. This enables automated adjustment deviations for consistent, high-quality welding. Loss of time is minimised because measuring and welding take place simultaneously with the arc sensor. Workpiece distortion, such as thermal expansion, is directly compensated for. CLOOS arc sensor thus combines productivity with optimised quality.

Tandem weld – Efficient welding times two

Tandem welding can be universally applied to both thin and thick plate welding. In the Tandem Weld process, two arcs burn in a common molten pool. The process is based on two electrically separated processes to match each other perfectly. This possibility opens up a multitude of combinations. The front wire ensures a safe penetration, and the back wire quickly fills big joints with filler material. The high deposition rate can result in weld speed and volume filling.

Tandem weld is suitable for thin and thick plates, allowing manufacturers to reduce welding times due to its high deposition rate. Manufacturers can reduce the component distortion and avoid extensive reworks due to the low heat input. Compensate material tolerances due to the gap-bridging ability. Tandem welding can be used for materials and thicknesses.

If manufacturers wish to maximise the efficiency of weld production? Then rely on Tandem Weld by CLOOS!

Digitalised production with CLOOS C-Gate

The digital revolution is in full swing, and welding is no exception. The digital revolution is in full swing, including welding. Monitoring and controlling production in real-time is crucial. With CLOOS C Gate, all digital solutions are in one place.

How CLOOS can help:

Digitalised production provides real-time monitoring and control on an integrated platform.

Interlinked robot welding solutions that increase productivity with precision and speed.

Sustainable technologies harmonise welding processes with environmental goals.

Human-robot collaboration encourages a versatile workforce and helps eliminate the shortage of skilled labour.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Modern, decentralised applications require automated systems that guarantee high connectivity and maximum precision. The new WAGO I/O System Field, with a protection class of IP67, is a reliable solution offering high performance, designed for time-sensitive networking (TSN), and is unshakeable in the harshest environmental conditions.

The IP67-rated I/O System Field is optimised for dependable, cabinet-free automation. The modules mount exactly where you need them – at the heart of the action, close to sensors and actuators. This adaptability reduces the required cabling and simplifies commissioning, maintenance, and diagnostics. The system offers no-compromise protection with pressure-cast zinc housings for extremely harsh environments or robust yet lightweight plastic housings for mobile applications. The modules operate reliably at temperatures ranging from −25 to +70°C (- 13°F to +158°F) and are immune to electromagnetic interference due to internal shielding. Slim housing variants and lateral mounting options provide more space.

Innovative load management ensures that the system’s power is fully utilised via supply and output current load management. Current and voltage can be recorded and evaluated per channel. Overload limits can be set for individual channels. As a result, errors can be detected faster and more differentiated in the event of faults – errors are also more easily predicted, which is essential for future trends such as predictive maintenance.

In combination with IO-Link, the IO System Field fully demonstrates its strengths as a flexible “IO distributor” for both data collection and distribution. The prominent communication standard enables seamless data flow from the control to the sensor and actuator level. This considerably simplifies configuration and cabling.

Furthermore, completely new possibilities arise for diagnostics, parameterisation and device identification.

Whether on a packaging machine or a robot arm, the modules of the I/O System Field mount exactly where you need them – at the heart of the action, close to sensors and actuators.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

According to the Food and Agriculture Organisation, 1.8 billion people face total water scarcity in 2025, making it crucial to rethink how we use this precious resource. A change in mindset is necessary, as water management approaches focused on supply are no longer viable. Raveendra Bhat, Area Sales Director at Water Utility INDO Region, Grundfos, discusses the urgent need to address water scarcity in India.

Envision a world where every ounce of water is precious, women walk miles to fetch water, farmers watch their crops shrivel due to a lack of irrigation, and cities face shutdowns because their water supplies have run dry. It is not a dystopian future; it’s the reality for billions today.

According to the Food and Agriculture Organisation, 1.8 billion people face total water scarcity in 2025, making it imperative to rethink how we use this precious resource. As people become more aware of the ecological limits of watersheds, the history of water is seemingly challenged. It requires a change in mindset, as water management approaches focused on supply are no longer viable.

Technology continues to be an important force in transforming the water sector, but the cultural shift alongside it holds the key to achieving meaningful change. For example, the Grundfos facility in Chennai, which was built as the first commercial green building, was later accredited as a LEED Platinum–certified factory. It stores about 53% of its rainwater, recycles its wastewater for landscaping, and has a solar array that gives it a minimal carbon footprint. These illustrations serve as a reminder that addressing water issues calls for a fundamental change in people’s attitude, where every drop is valued and conserved.

To make a difference, smarter ways of managing demand and avoiding waste need to be implemented. Grundfos water management approaches have primarily focused on supply and expansion, rather than demand management. Water management is currently fragmented, with different sectors operating in isolation. Confronting the crisis will require collaboration, shifting from a supply-driven approach to one that prioritises the fair and sustainable use of water, ensuring that this finite resource remains available for future generations.

Technological intervention: Key driving factor for sustainable change

To address the increasing water crisis, it needs to transition from a linear ‘use-and-dispose’ model to a circular model in which wastewater will be treated as a viable resource rather than waste. This switch can relieve the strain on freshwater supplies and encourage sustainable water use. Today, in Chennai, Tamil Nadu, about 49% of treated wastewater is reused; in comparison, Delhi and Hyderabad reuse only 19% and 6%, respectively, showing that there is still vast untapped potential for recycling and reusing water in India.

Decentralised wastewater treatment systems are key since they treat water near where it is used, enabling greater reuse of non-potable water for irrigation and industrial uses. One widely cited success story is Alappuzha in Kerala, where community-level wastewater treatment plants have improved sanitation and allowed for local reuse. Complementing these efforts, clean energy initiatives are being integrated into water management systems elsewhere. Karnataka Surya Raitha Scheme aims to provide solar-powered irrigation pumps to farmers, minimising dependence on conventional energy sources and promoting sustainable farming practices to provide additional income.

The systems are further enhanced by integrating smart infrastructure technologies such as demand-driven distribution technologies developed by Grundfos using sensor-based high-efficiency pumps that adjust automatically to water demand, cutting waste and expense. To scale these solutions, massive infrastructure investment is vital. The Central Pollution Control Board (CPCB) mandates specialised pumping systems for the fine transportation of treated water for reuse in various sectors.

By bringing together local reuse systems, renewable energy mappings, and intelligent pump technologies, India can transform water management into a circular sustainable model that ensures water for generations.

Opportunities

To foster sustainability in water utilities, reducing carbon footprint, utilising energy-efficient technologies, and utilizing renewable energy like solar is crucial. Shift to powering water systems with renewable energy and energy-efficient technologies. Utilities can provide clean water to remote areas using off-grid, solar-powered pumping systems. Such decentralised systems enable better service coverage; they also help build sustainable socio-economic development by giving communities access to water reliably and affordably.

Meanwhile, Grundfos iSOLUTIONS are transforming the operations of water utilities. These systems deploy smart meters, cloud analytics, and real-time monitoring to improve water flows. Utilities will be able to identify leaks instantly, tune the pumping to actual demand, and have more accurate data for planning maintenance and upgrades. This greatly minimises non-revenue water (NRW), energy use, and operating expenses.

Real-world impact: A case study from Cambodia

One compelling example is the sustainable water systems from the Takeo province of Cambodia, where the Takeo Safe Water Supply utility experienced significant problems with water pressure and high NRW. They had water wasted, used too much energy, and had maintenance challenges that led to unreliable service.

To solve this, the utility worked with Grundfos to install a demand-driven distribution system and a smart sensor-based system that varies pump pressure according to real-time water demand in the network. This helped the utility keep water pressure even, minimise leaks, and reduce waste of water and energy. This led to a 20% saving in energy use and 13% water loss at the utility, as well as greater service reliability and reduced maintenance costs. This illustrates how sustainable practices and smart technologies can lead to significant gains in green and operational metrics.

Now and future: A cultural shift in communities mindsets

In Bengaluru, a model of sustainable water management can be found at the GM Infinite apartment complex in Jalahalli West. The residents use an advanced treatment system that purifies wastewater from the sewage treatment plant (STP) to make drinking water, and they recycle about 1.5 lakh litres a day for toilet flushing and cleaning. It greatly diminishes their dependence on fresh water and is a model for any housing development seeking to become water-resilient. This tale illustrates how a cultural transformation driven by community, education, and sustainability can yield deep and durable results.

Renewable energy, digital transformation, and new water management methods could enable the water industry to pioneer a path toward a sustainable and efficient future. However, resilient utilities do not sprout overnight; they are nurtured by a culture that welcomes change, seeks efficiency, and cares about sustainability.

To make water utilities sustainable over the long term, a culture of sustainability must be developed, encompassing collaboration, leadership, and a commitment to continuous innovation. The question is not whether this needs to be done but how quickly society can come together to ensure clean water for future generations. Bangalore is a contemporary story, driven by a single choice, step, and drop.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Seco Component Guidance is a web-based tool that allows customers to upload 3D part models and receive instant tool recommendations. It uses advanced feature detection technology to analyze user-uploaded models, identifying features like pockets and edges.

Seco Component Guidance allows customers to upload 3D part models and receive instant tool recommendations tailored to their specific needs. A web-based application, this new tool performs complex calculations in the cloud, ensuring quick access and results without requiring a powerful PC.

Optimal recommendations delivered instantly

Seco Component Guidance uses advanced feature detection technology to analyse user-uploaded 3D part models. The application automatically identifies pockets, holes, edges and other part features, then provides tooling recommendations catered to the part’s specific design.

Erik Ekqvist, Product Manager, Seco, said, “Component Guidance is a powerful tool that takes full advantage of the latest in technology.” The software can significantly streamline the procurement process. It will also prove a valuable tool in ensuring estimate accuracy, as manufacturers bidding on a new part can very quickly determine the associated tooling needs and costs.”

Prioritising cost efficiency

When determining tooling recommendations, Seco Component Guidance automatically identifies opportunities to produce multiple features with the same tool. Plus, the system takes a user’s purchasing history into account, allowing it to minimize costs by giving precedence to tools that are already on hand.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Yash Dynamics Private Limited offers locally manufactured PTFE liners in India, reducing reliance on imports and offering high-quality, cost-effective solutions for automotive control cables in high-temperature, high-performance applications.

Automobile manufacturing is changing rapidly to meet the latest demands for luxury, safety, and long-lasting performance. Amenities like throttle, clutch brake systems, have become more standard.

PTFE liners allow the incorporation of these features into automotive control cables with greater efficiency and reliability. Both consumer demand and evolving markets drive the increased use of mechanical functions in cars. These advances require control cables to work harder at higher temperatures continuously for years. The use of control cables will continue to grow thanks to:

In addition to vehicle components that are more futuristic and consumer-facing, new designs for fuel and braking systems, powertrains, chassis, and interiors also require high-performance cabling. Here, PTFE liners play key roles wherever cables need thinner but better and smoother liner materials that can withstand ever-increasing service temperatures.

Characteristics of PTFE liners that make them an excellent choice for automotive applications include:

Indian market scenario

The present PTFE liners market for control cables is being served by limited international tube manufacturing companies, which makes any Indian automotive OEM company largely dependent on international sourcing, leaving them with:

PTFE tube manufacturing challenges

Raw material sourcing presents a significant challenge. Most PTFE fine powder manufacturers worldwide already have technical support agreements with existing international PTFE tube manufacturers, leading to limitations in technical support, process expertise, equipment specifications, and more. Identifying candidates for raw material grades based on properties and standards for a specific application is also tricky for any PTFE tube manufacturer.

Manufacturing requirements are also a challenge. PTFE tubing demands strict quality parameters due to its application and tight tolerances. Key quality parameters of PTFE tubes are surface smoothness, ovality, tensile strength, elongation, concentricity, ID/OD maintenance, and long length for control cables. This makes the manufacturing technique and equipment highly complex.

Another major barrier to manufacturing PTFE tubes is that production technology is proprietary in nature, and machine lines are to be designed and developed jointly by PTFE tube manufacturers and raw material technical collaborators.

Yash Dynamics

Yash Dynamics Private Limited is an Indian company specializing in high-grade PTFE tubing and liners using advanced paste extrusion technology. Focusing on the Indian fluoropolymer industry, particularly for automotive OEMs, the company produces long-length PTFE extruded tubing at its facility in Dehradun, Uttarakhand, which includes a fully equipped quality assurance laboratory.

Currently operating two extrusion lines, Yash Dynamics plans to expand by adding two more lines each year. The company holds a technical agreement with India’s only PTFE fine powder manufacturer and offers a range of PTFE liners for various applications, including throttle and clutch cables etc. They provide prototype liners to automotive manufacturers before moving into larger production volumes.

Yash Dynamics has ISO 9001:2015 certification and uses high-quality PTFE fine powder to ensure durability and smooth operation. PTFE’s high melting point makes the products ideal for high-temperature environments, reducing issues like stiction commonly found in standard cables.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

EMO Hannover 2025 will showcase the latest in automation, AI, and sustainable metalworking from September 22 to 26, offering future-ready solutions for global manufacturers.

EMO Hannover 2025, the world’s biggest production technology trade expo, will return from September 22 to 26, showcasing cutting-edge developments in automation, collaborative robots, 3D printing, and AI-powered process chains. As metalworking advances rapidly, the event will assist industry professionals in evaluating and implementing the most appropriate technology for long-term growth.

Dr. Markus Heering, Executive Director of VDW (German Machine Tool Builders’ Association), stated, “EMO is more than just a tradeshow. It is a unique international platform for dialogue between manufacturers and users. The show will include international exhibitors, expert-led forums, and focus zones on the major topics driving industry transformation.”

Empowering Industry Transformation

Companies worldwide are under pressure to modernise in response to rising prices, tougher emissions objectives, and increased global competition. EMO Hannover will exhibit solutions for advanced industries like aerospace, medical technology, and renewable energy, which require greater precision, productivity, and material innovation.

As factories struggle to find trained personnel, digital technologies and AI become increasingly important. EMO will assist decision-makers in reducing investment risks by demonstrating solutions that have been proven to boost efficiency and offer new business opportunities.

Focus on Automation and Sustainability

The programme will emphasise automation as a critical facilitator of both series and single-piece production. The Cobot Area will demonstrate how collaborative robots may help create efficient, adaptable systems.

Bertram Kawlath, President of the German Engineering Federation (VDMA), stated, “Mechanical engineering is an enabler of climate-friendly transformation. The sustainability area will include technology that cuts energy use while using renewable resources and circular economy ideas.

Digitalisation and Predictive Intelligence

With the increasing integration of IoT and AI, digital process chains improve transparency and enable predictive maintenance. EMO will feature innovative technology that assists manufacturers in increasing uptime and reducing operational hazards.

Ahead of the event, updates from participating companies and previews of their offerings can be found on the official website:

🔗 https://visitors.emo-hannover.de/en/landingpage/c-level

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.