ZETWERK Electronics begins construction of new advanced facility in Bengaluru to boost manufacturing capacity and support India’s global manufacturing goals.

ZETWERK Electronics, one of India’s top Electronics Manufacturing Services (EMS) businesses, has started building on its new advanced manufacturing facility in Devanahalli, Bengaluru, with a traditional bhoomi puja ritual.

This significant investment underscores ZETWERK’s commitment to India’s goal of becoming a global manufacturing powerhouse. The new facility is intended to improve the company’s manufacturing capabilities in high-growth industries such as industrials, communications, automotive, consumer durables, and key electronics.

Josh Foulger, President, ZETWERK Electronics, stated, “This investment underscores our commitment to delivering world-class manufacturing solutions from India. With Bengaluru’s strong industrial ecosystem and connectivity, we are well-positioned to serve global markets and meet international quality benchmarks.”

Rahul Sharma, Co-Founder of ZETWERK, added, “This facility significantly scales our manufacturing capacity, allowing us to offer faster, more precise, and larger-scale production. We remain focused on delivering superior value to our customers.”

The facility will serve as a critical pillar in ZETWERK’s strategy to create localised, scalable, and cost-effective infrastructure aligned with automation, sustainability, and workforce upskilling.

Zohra Khan, CEO of IPEC Project Services-India, said, “ZETWERK has consistently demonstrated precision and reliability. This facility represents a bold move toward globally competitive, innovation-driven manufacturing in India.”

This development strengthens ZETWERK’s position in the EMS sector, reinforcing its role in shaping the future of global supply chains through high-quality, sustainable, and tech-driven manufacturing.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Nvidia and Siemens have expanded their partnership to accelerate AI adoption in manufacturing, aiming to boost efficiency and enable smart factory development.

Siemens and NVIDIA have expanded their collaboration to accelerate the adoption of industrial AI and digitalisation, thereby advancing the development of the future factory. The cooperation brings together Siemens’ industrial automation experience with NVIDIA’s AI and fast computing technologies.

Jensen Huang, founder and CEO of NVIDIA, stated, “Modern manufacturers face mounting pressure to boost efficiency, enhance quality, and adapt swiftly to changing market demands. Our partnership with Siemens is bringing NVIDIA AI and accelerated computing to the world’s leading enterprises and opening new opportunities for the next wave of industrial AI.”

Roland Busch, president and CEO of Siemens AG, commented, “AI is fundamentally transforming manufacturing and infrastructure. Over the last three years, we’ve worked closely to merge AI models and high-performance computing with industrial data and domain know-how. Together, Siemens and NVIDIA are now empowering companies across every industry to unlock the scaled impact of AI in the physical world.”

Siemens Xcelerator and NVIDIA Omniverse™ joined together in 2022 to create an industrial metaverse. It now encompasses work on generative AI, industrial AI, and robotics.

Siemens integrates NVIDIA technology throughout the Xcelerator platform. The Teamcenter Digital Reality Viewer integrates real-time ray tracing into product lifecycle management, enabling businesses to visualise and interact with photorealistic digital twins.

This technology is used by HD Hyundai to develop vessels driven by hydrogen and ammonia, managing millions of components in real time and lowering design iteration time from days to hours. BMW Group and Siemens used Simcenter Star-CCM+ software with NVIDIA Blackwell GPUs and CUDA-X™ libraries to deliver 30x faster transient aerodynamics simulations.

Siemens has developed NVIDIA GPU-certified industrial PCs, which offer 24/7 industrial computing and provide a 25x acceleration in AI workloads such as robotics, inspection, and predictive maintenance.

Siemens’ Industrial Copilot for Operations utilises NVIDIA NeMo™ microservices and NVIDIA RTX PRO™ 6000 Blackwell GPUs to provide real-time AI support and reduce reactive maintenance time by 30%. The companies are also using NVIDIA BlueField® DPUs to give AI-powered cybersecurity to operational technology systems, increasing visibility and protection.

The expanded alliance seeks to facilitate the rapid and efficient deployment of AI technologies in industrial environments.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Dassault Systèmes provides virtual worlds to enhance real life with their 3DEXPERIENCE platform, which conceives innovative software solutions for 3D modelling, simulation, information intelligence, and collaboration, bringing them to life. Ravikiran Pothukuchi of Dassault Systèmes shares how their 3DEXPERIENCE platform is truly the face of smart manufacturing and driving Industry 4.0 adoption.

Dassault Systèmes has been a key player in providing innovative digital solutions to industries. How do platforms like CATIA, DELMIA, and ENOVIA integrate into smart manufacturing ecosystems and support product lifecycle management?

Dassault Systèmes’ CATIA, DELMIA, and ENOVIA applications are integral to the 3DEXPERIENCE platform, enabling smart manufacturing and effective product lifecycle management. CATIA is used for product design and engineering, supporting everything from conceptual development to detailed modelling. It supports model-based systems engineering and simulation-driven design, ensuring that products are optimised for performance and manufacturability. CATIA integrates with DELMIA to validate designs that can be efficiently produced within real-world manufacturing constraints.

DELMIA focuses on three key aspects of manufacturing. DELMIA’s Digital Manufacturing (DM) applications allow manufacturers to simulate, plan, and optimise production processes before implementation. It supports virtual commissioning and real-time monitoring, utilising IoT and analytics to enhance efficiency. DELMIA DM aligns engineering designs and manufacturing processes, managing manufacturing bills of materials (MBOMs) and process plans to maintain consistency and traceability. DELMIA’s Planning & Optimisation Apps help organisations to carry out their Enterprise Business Planning (S&OP, APS) from Demand to Distribution with a rich and powerful optimisation engine. Finally, DELMIA’s Manufacturing Operations Management (MOM) Applications monitor shop floor execution in real-time to maintain traceability, genealogy, quality, and maintenance.

ENOVIA is collaborative and manages data. It manages product data, configurations, and project timelines while supporting change management, compliance tracking, and lifecycle governance. ENOVIA enables cross-functional collaboration and ensures that stakeholders are aligned throughout the product lifecycle. In short, ENOVIA is an Enterprise IP & Knowledge management platform powered by NETVIBES’ powerful Analytics engine to provide insights into every facet of the Product Lifecycle.

How does Dassault Systèmes help manufacturers adopt Industry 4.0 technologies such as AI, IoT, and cloud computing to drive automation and data-driven decision-making? Is the same approach followed for MSMEs?

We support manufacturers through our unified 3DEXPERIENCE platform, a digital foundation for smart manufacturing. The platform is available on the cloud, making it accessible and scalable for companies of all sizes. This cloud-based approach eliminates the need for heavy IT infrastructure, enabling real-time collaboration, streamlined deployment, and integration across global operations. For manufacturers, especially MSMEs, this reduces upfront costs and simplifies the adoption of advanced technologies. AI is embedded throughout our solutions to enhance automation and data-driven decision-making.

For MSMEs, we focus on accessibility and scalability. We offer modular, industry-specific applications and subscription-based pricing models, allowing smaller firms to adopt only the tools they need. Additionally, we collaborate with local partners and innovation hubs to provide training, support, and implementation services, helping MSMEs overcome barriers to digital transformation. This democratised approach ensures that even small manufacturers can leverage Industry 4.0 technologies to enhance productivity, agility, and competitiveness in a rapidly evolving industrial landscape.

As global supply chains face disruptions, how do your platforms help manufacturers enhance supply chain resilience, particularly in managing complex supplier networks?

Our platforms help manufacturers strengthen supply chain resilience by using virtual twin technology to anticipate and respond to disruptions. With AI-driven part standardisation, companies can quickly identify alternative components and suppliers, reducing dependency on single sources. Virtual twins of factory systems perform real-time simulations and reschedule operations, ensuring agility in the face of unforeseen disruptions. This is critical in regulated sectors, such as aerospace, where export controls and localisation policies influence sourcing. The 3DEXPERIENCE platform enhances visibility, collaboration, and adaptability across complex supplier networks, keeping production on track and businesses future-ready.

Dassault Systèmes helps manufacturers enhance supply chain resilience, particularly in managing complex supplier networks, through its integrated 3DEXPERIENCE platform. This platform offers end-to-end visibility, collaboration, and risk management tools.

The platform enables companies to create virtual twins of their supply chains, allowing them to simulate disruptions, evaluate alternative sourcing strategies, and optimise logistics in real time. It supports multi-tier supplier mapping, helping businesses understand dependencies and vulnerabilities across their entire network, not just direct suppliers.

With built-in AI and analytics, manufacturers can forecast demand more accurately, monitor supplier performance, and identify early warning signs of potential disruptions. The platform also facilitates collaborative planning across global teams and suppliers, ensuring faster response and recovery during crises.

As automation advances rapidly and generates vast amounts of data, how do your solutions incorporate feedback mechanisms to strengthen and ensure cybersecurity?

As automation advances and connected systems generate vast volumes of data, we ensure cybersecurity through a layered approach embedded within the 3DEXPERIENCE platform. The platform is designed with secure-by-design principles, incorporating continuous feedback loops from user behaviour, system performance, and threat intelligence.

Real-time data monitoring and analytics enable the early detection of anomalies, while built-in feedback mechanisms help identify vulnerabilities and dynamically adapt security protocols. Role-based access control, data encryption, and traceability ensure that sensitive IP and operational data remain protected across the product lifecycle.

We also collaborate with industry partners and government frameworks to align with evolving global cybersecurity standards. With increasing cyber risks, particularly in the manufacturing and critical infrastructure sectors, the 3DEXPERIENCE platform enables customers to proactively manage threats, maintain operational continuity, and build resilience as digital transformation advances.

As automation scales and industrial systems become more connected, the need for built-in, adaptive cybersecurity is critical. Dassault Systèmes addresses this by embedding continuous feedback mechanisms into its 3DEXPERIENCE platform, enabling the monitoring, detection, and real-time response to threats.

The platform enables secure collaboration across design, engineering, and manufacturing by enforcing role-based access, encrypted data exchange, and end-to-end traceability. Feedback loops from user activity, system performance, and threat patterns help continuously refine security protocols and respond to anomalies swiftly. These insights inform policy adjustments, vulnerability patching, and risk-based access controls, thereby creating a self-improving defence framework.

By integrating cybersecurity as a core part of its platform architecture rather than treating it as an add-on, Dassault Systèmes ensures that enterprises can scale automation and data-driven innovation securely, even in highly regulated industries such as aerospace, defence, and life sciences.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

DGT and Shell India launch EV training program to equip youth with green skills and job-ready certifications.

The Directorate General of Training (DGT) of the Ministry of Skill Development and Entrepreneurship (MSDE), in partnership with Shell India, has developed a Green Skills and Electric Vehicles (EV) training program. Edunet Foundation will implement the programme in chosen Industrial Training Institutes (ITIs) and National Skill Training Institutes (NSTIs) throughout Delhi-NCR, Gujarat, Maharashtra, Tamil Nadu, and Karnataka.

The curriculum uses an organised, multi-tiered training model:

The course covers EV systems, diagnostics, battery technologies, digital tools, and safety standards. A specific Training of Trainers (ToT) programme will upskill more than 250 trainers. Shell and DGT will co-brand the certification and provide placement assistance to participants. Aligned with India’s net-zero goals and EV policies, the programme addresses the rising demand for skilled green mobility professionals.

Specialised EV skill laboratories will be developed at selected ITIs and NSTIs to give hands-on training by industry standards.

Jayant Chaudhary, Minister of State (Independent Charge), MSDE, and Minister of State for Education, said, “Our collaboration with Shell India reflects the government’s deeper commitment to aligning skilling with sustainability. Green energy, electric mobility, and the broader climate transition are not just environmental imperatives—they represent a generational opportunity for India to lead through innovation, talent, and enterprise. This initiative is part of our larger vision to create a workforce that is not only job-ready but also climate-ready.”

Smt Trishaljit Sethi, Director General, DGT, MSDE, stated, “This partnership with Shell India is a focused step in bringing cutting-edge training infrastructure and industry-relevant curriculum into our ITIs and NSTIs. By integrating electric vehicle technologies into vocational training, we are ensuring that our students gain hands-on experience aligned with real-world demand. With joint certification, trainer upskilling, and placement support built into the programme, this initiative will significantly strengthen the employability of our youth in the green mobility sector.”

Mansi Madan Tripathy, Chairperson, Shell Group of Companies in India & Senior Vice President, Shell Lubricants, Asia-Pacific, stated, “At Shell, we aim to support local communities by enabling future employment opportunities. Equipping youth with green energy skills is an important step towards building a lower-carbon future. Through our collaboration with DGT and Edunet Foundation, we are providing students with practical and future-ready expertise in green energy and electric mobility. This initiative empowers young people to thrive in an evolving energy landscape and contribute towards India’s net-zero ambitions.”

The DGT–Shell India initiative equips youth with green skills and certifications to boost employability in a sustainable economy.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Schneider Electric, with Microsoft, introduces an AI copilot to boost industrial automation through smarter, faster, and more efficient operations.

Schneider Electric introduced next-generation Industrial Copilot, developed in partnership with Microsoft. This generative AI-powered assistant is intended to improve open automation ecosystems by increasing operational efficiency, flexibility, and intelligence across several industries.

The Copilot is integrated into Schneider Electric’s open, software-defined automation environment, the EcoStruxure Automation Expert Platform. It simplifies engineering procedures, accelerates application deployment, and facilitates collaboration. It reduces the number of repeated operations, streamlines application development, and speeds up the delivery of high-quality solutions to market.

The AI assistant makes real-time advice, facilitates predictive maintenance, allows for fast troubleshooting, and combines data for better decision-making. These features reduce machine downtime, decrease manual labour, and lower operational expenses.

Arvind Kakru, VP, Industrial Automation, Schneider Electric India, stated, “India’s manufacturing sector is rapidly evolving, demanding greater flexibility and efficiency, and Open Automation plays a pivotal role in achieving this goal. Our AI Copilot, developed with Microsoft and building on our deep domain expertise, doesn’t just operate within an open ecosystem – it strengthens it. It simplifies engineering, accelerates deployment, and empowers teams to do more with less, all while reinforcing the core values of openness, modularity, and collaboration.”

The EcoStruxure Automation Expert Platform is designed to function smoothly with various hardware and software platforms. The Copilot connection improves real-time data access, allowing engineers, operators, and AI systems to respond faster and more accurately, as well as coordinate better.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Ransomware’s attacks are no longer just targeting data centers and banks—they’re aiming to freeze entire supply chains. From order management to transport coordination, no system is off-limits.

In the daily course of work and associated cyberthreat awareness activities, we often picture cyberattacks targeting data centres, banks, or tech firms.

What’s often overlooked, however, is the growing vulnerability of the logistics and manufacturing ecosystem in today’s hyperconnected world. Ransomware actors are no longer focused solely on financial institutions or technology giants. Increasingly, they are attacking ERP systems, inventory management platforms, transport coordination software, and similar systems that form the backbone of an organisation’s supply chain. When targeted, cyberattacks on these services can halt operations entirely and hold them to ransom—pun intended.

From the moment raw materials are ordered to the time finished goods reach store shelves, each step relies on connected systems. This connectivity, while a key enabler, has also become a critical weakness.

The shift in attacker focus is not unexpected. Supply chains present a high-impact opportunity. When a manufacturer is unable to dispatch goods or a logistics provider loses control over routing and scheduling, the consequences are swift and expensive. Attackers understand that the urgency of such disruptions increases the likelihood of ransom payments, positioning the sector as an increasingly attractive target.

In May 2025, UK logistics firm Peter Green Chilled experienced a ransomware attack that disrupted operations and revealed weaknesses in the food supply chain. The company, which supplies Tesco, Sainsbury’s, and Aldi, had to pause order processing, placing thousands of food items at risk of spoilage and financial loss. The incident underscores a shift in cybercriminal tactics—from data theft to operational disruption. Threat actors are now focusing on time-sensitive sectors like food logistics, where even brief delays can be damaging. This attack, along with others affecting Marks & Spencer and Co-op, highlights the urgent need for stronger cybersecurity and greater supply chain resilience. Ransomware groups are no longer just targeting files—they are aiming to paralyse entire supply chains.

When it comes to securing supply chains, it’s important to recognise their complexity. They involve numerous stakeholders, including vendors, transporters, warehouses, and technology providers. All of these parties are digitally connected, but not all enforce cybersecurity standards as rigorously as the organisation itself. Attackers often exploit this disparity.

Frequently, cybercriminals don’t target the main manufacturer directly. This may be because the primary target is better protected and more difficult to breach. Instead, attackers look for quicker access by compromising smaller vendors or associates with weaker defences, using them as entry points. Many of these smaller entities rely on outdated software or systems that have gone without updates for years. These legacy systems were never built to defend against today’s sophisticated cyber threats. As a result, attackers can gain access and lock down critical systems—be it order management, warehouse control, customer databases, or all of the above.

Such incidents are no longer uncommon. They are becoming a routine challenge in manufacturing and logistics. Even short periods of downtime can result in weeks of backlog, especially in environments where schedules are tight and profit margins narrow—not to mention the reputational damage and erosion of consumer trust.

To defend effectively against supply chain attacks, begin by mapping your digital supply chain. Identify where your operations depend on third-party digital services such as fleet management, warehouse automation, or vendor coordination. Every endpoint should be seen as a possible risk vector.

Next, adopt Zero Trust principles. Practices like identity verification, least privilege access, and network segmentation must be embedded into the culture from the moment a new third-party associate is onboarded. This ensures that, even if part of the infrastructure is compromised, the damage can be contained.

Real-time monitoring and swift incident response are also critical. Delays in identifying and reacting to breaches can magnify the damage. Continuous monitoring and a clearly defined response protocol for ransomware incidents—covering prevention through to mitigation—are essential.

Equal emphasis should be placed on robust backups and continuity planning. Regularly test backups and recovery mechanisms to prevent unexpected failures. Store critical configurations in isolated environments for added protection.

Finally, focus on employee education and maintain ongoing awareness. Through refresher courses and targeted training efforts, instil a culture of cybersecurity consciousness across your workforce. Every staff member must understand their role in maintaining daily cyber hygiene. Training those directly involved in the supply chain is just as vital as addressing technical vulnerabilities.

Manufacturing and logistics organisations must treat cybersecurity as an integral part of operational safety. Just as you wouldn’t allow faulty machinery on the floor, you shouldn’t tolerate insecure digital systems in your network. This mindset must be adopted across the entire organisation and its supply chain—not confined to the IT department.

Authored by Binoy Koonammavu, Founder & CEO of ValueMentor

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Yash Dynamics Pvt Ltd, based in Dehradun, is India’s pioneering PTFE extruded tube manufacturer using advanced vertical paste extrusion technology. It delivers high-performance, ISO-compliant solutions for diverse industrial and medical applications.

Yash Dynamics Private Limited is an Indian-origin fluoropolymer processing company specializing in the manufacturing of superior quality PTFE (Polytetrafluoroethylene) tubes using advanced vertical paste extrusion technology. With a strong commitment to innovation and quality, the company is steadily establishing its presence in the Indian fluoropolymer industry, focusing specifically on PTFE extruded tubing.

Located in Dehradun, Uttarakhand, Yash Dynamics operates a dedicated manufacturing facility spanning 25,000 sq. ft., equipped with advanced vertical paste extrusion machines and a fully functional in-house quality assurance laboratory. This facility enables the company to deliver consistent, high-performance PTFE tubes tailored to the exact needs of diverse industries.

Yash Dynamics is the first in India to acquire technical knowledge for PTFE vertical paste extrusion technology from the country’s only fluoropolymer manufacturing conglomerate. This unique expertise ensures that all products comply with stringent international standards such as ISO, ASTM, and DIN. Through reverse engineering and rigorous in-house testing, the company guarantees that its tubes meet exacting quality parameters.

Mission

Yash Dynamics aims to empower its clients and partners by providing premium Make-in-India PTFE tubes delivered promptly to their doorsteps. The company is committed to building long-term relationships based on trust, integrity, and mutual respect, with collective growth and success.

Core Advantages

The PTFE tubes are manufactured using high-grade raw materials to ensure reliable performance even in extreme industrial conditions.

With state-of-the-art extrusion technology and strict quality controls, Yash Dynamics ensures smooth finishes, precise dimensions, and tight tolerances.

Company processes are aligned with ISO standards, and every team member contributes to maintaining consistent manufacturing quality.

A dedicated team of engineers and technical specialists offer valuable guidance throughout product development and manufacturing stages.

Yash Dynamics works closely with clients to deliver personalised solutions and seamless service from inquiry to final delivery.

With domestic production capabilities and streamlined logistics, the company can meet urgent project requirements efficiently.

Quality

Quality plays a central role in Yash Dynamics’ operations. Every product batch undergoes rigorous inspection and testing to ensure compliance with both domestic and international standards. The company’s in-house testing laboratory verifies technical specifications and certifies each shipment before dispatch.

Application Segments

PTFE tubes manufactured by Yash Dynamics offer excellent torque control, pushability, and lubricity. Their rigid substructure helps prevent kinking and supports high-pressure applications in minimally invasive procedures.

PTFE’s chemical inertness and durability make it an ideal substitute for glass in aggressive chemical environments, offering long-term reliability and performance.

PTFE is widely used for insulating high-voltage cables and components, ensuring safety and performance.

PTFE tubing is suitable for fluid transfer systems, fuel lines, cable insulations, and mechanical control cables due to its lowest friction properties, broad temperature range (-270°C to +260°C) and excellent mechanical strength.

In 3D printers, PTFE tubing guides filament smoothly through Bowden extruders, effectively handling high nozzle temperatures while reducing friction.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

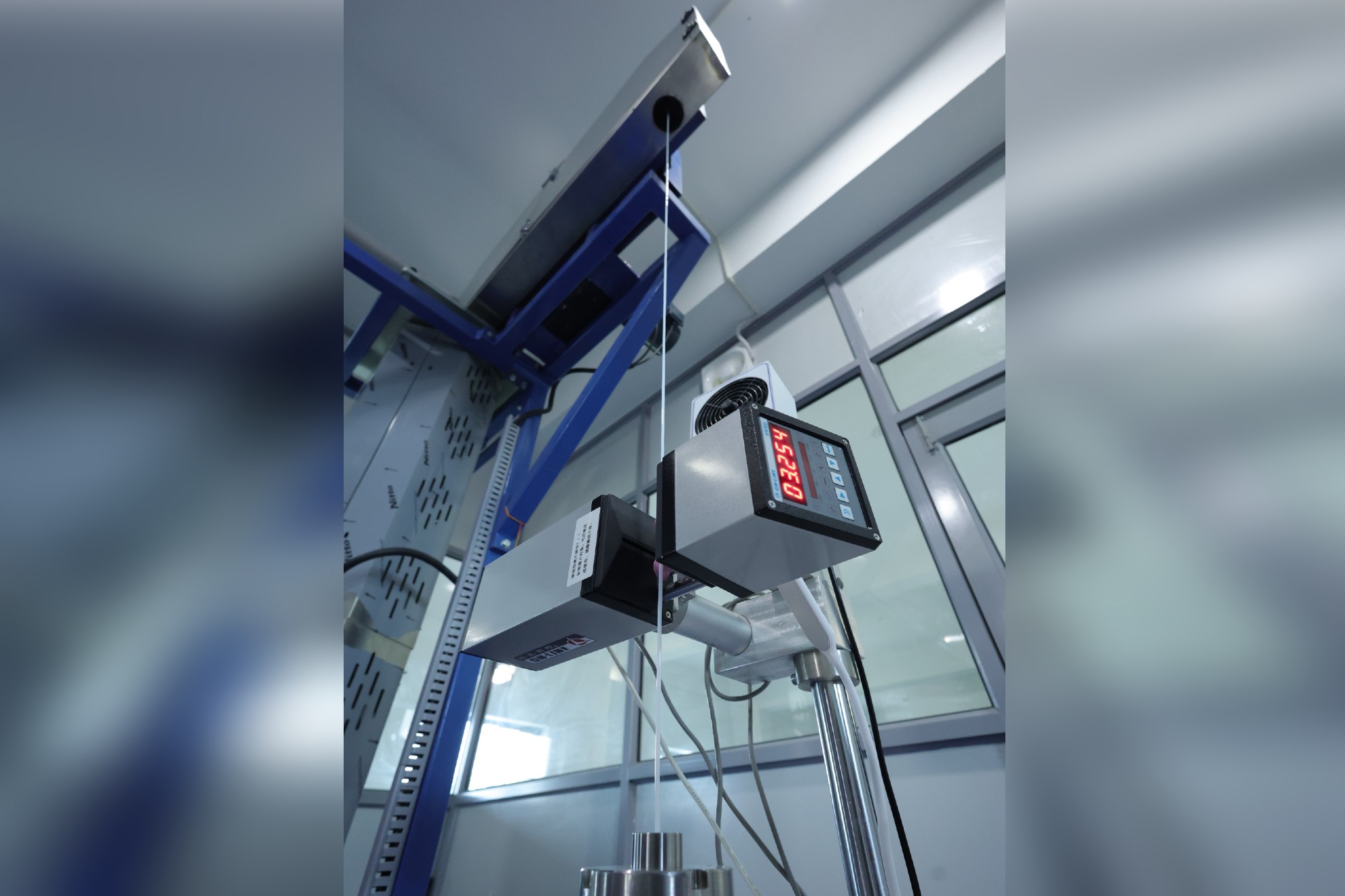

Moisture control is critical for the success of painting and coating applications in industrial settings. Desiccant dehumidification technology ensures optimal surface conditions, prevents corrosion, and enhances coating longevity, ultimately improving operational efficiency and reducing downtime across facilities.

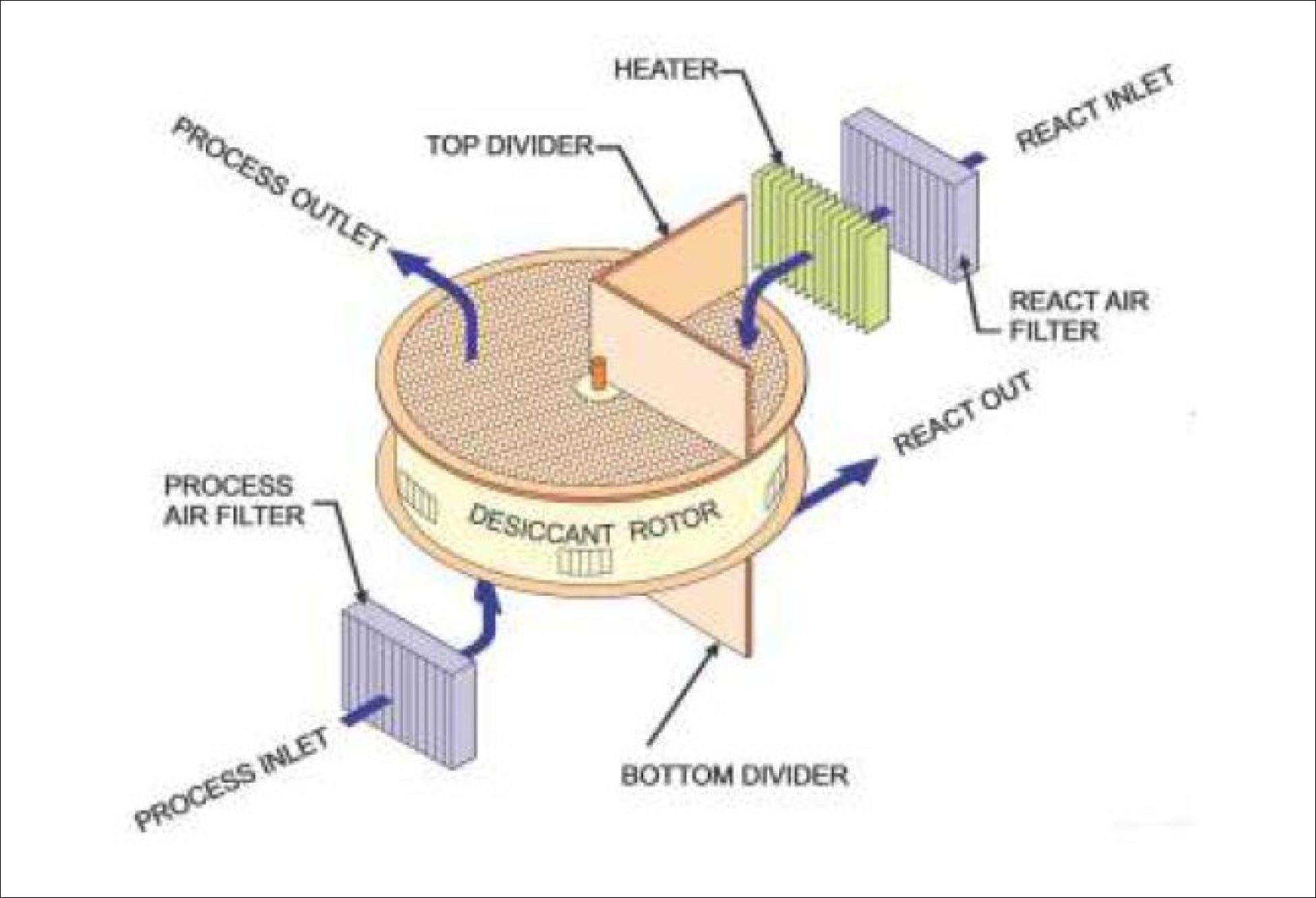

The role of a coating system is indispensable in an industrial setup, as it determines the efficacy of critical processes carried out within the facility. However, even the slightest trace of moisture in the plant can compromise operations, necessitating the deployment of desiccant dehumidifiers to create ideal environmental conditions. These systems are essential for maintaining humidity at optimal levels to ensure uninterrupted process execution.

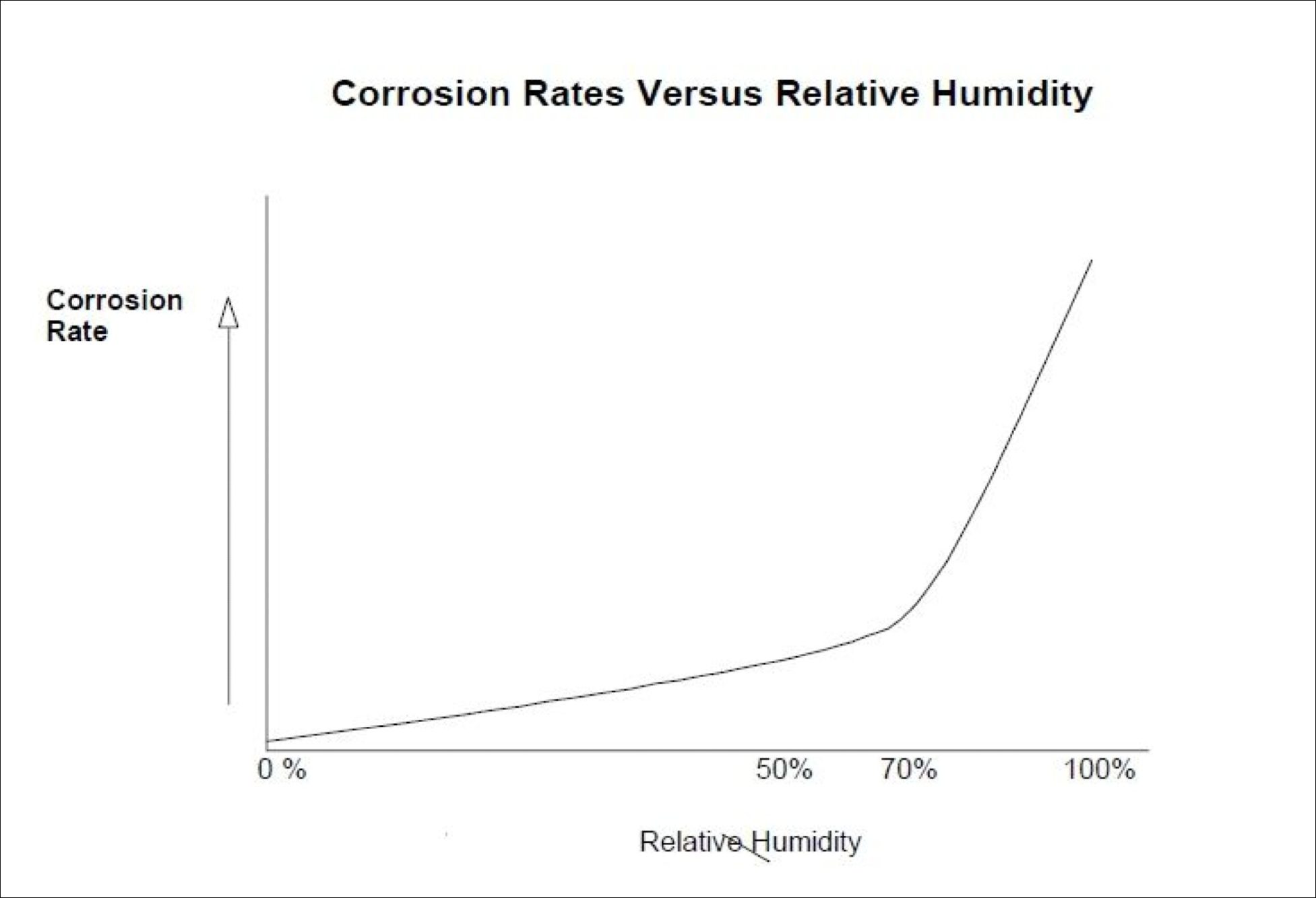

The importance of desiccant dehumidifiers becomes evident considering that humidity can deteriorate the coating system. Coating provides a protective layer to tanks, and moisture significantly reduces its lifespan. By preventing proper adhesion between the substrate and the coating, moisture leads to failures in critical operations. Therefore, efficient surface preparation is a prerequisite to ensure effective coating of cold-water ducts, cooling towers, FGD stack linings, absorbers, and rubber linings in acid tanks. Inadequate surface preparation can result in blistering, cracking, peeling, and cratering, ultimately causing premature failure of the coating system. Improper coating also affects highly sensitive and reactive chemicals stored in tanks, as it causes surface wear, leading to contamination and dilution of petrochemicals, chemical gases, and more.

Monsoon conditions and night-time temperatures worsen the problem due to the prevalence of cold weather, which increases moisture levels in the air. This leads to condensation on metal surfaces, initiating corrosion known as ‘flash rust’ or ‘rust bloom’. Given the severe impact of moisture on the efficiency and profitability of power plants, employing desiccant dehumidification technology becomes crucial to eliminate moisture from the facility. It proves effective in monitoring temperature, relative humidity (RH), and dew point, thereby ensuring comprehensive industrial coating by keeping humidity within a tightly controlled range.

Desiccant dehumidifiers are equipped with advanced technologies that support proper surface preparation for effective coating application. This helps prevent condensation and resists rust bloom during blasting and painting operations. The technology plays a key role in preventing curing failure by eliminating surface blistering. Additionally, it enables anti-corrosive painting and enhances intercoat adhesion, increasing the coating lifespan by 1.5 to 2 times and exceeding standard expectations.

These dehumidifiers maintain temperatures between 30°C and 35°C while achieving relative humidity levels below 55% inside tanks throughout blasting, painting, and coating jobs. They also maintain a constant -5°C dew point differential between air and surface temperature and a -12°C differential between the air inside the tank or silo and the external atmosphere.

Beyond controlling humidity for effective coating, dehumidifiers offer easy and cost-effective solutions. They contribute to cost savings of up to 2–4% of the total expense that would otherwise be incurred in corrosion-preventive painting. They also allow for year-round blasting, painting, and coating by maintaining ideal indoor conditions regardless of external weather. Their efficiency in regulating conditions at night further helps reduce unplanned power plant downtime caused by unfavourable weather.

Desiccant Dehumidification Operating Principle

As a result, these systems promote timely project completion and reduce overall costs by up to 35%. They enable on-time delivery and lower project expenses. Without dehumidifiers, blasting and painting would need to be performed in phases to avoid condensation between processes. This complicates the workflow, making it impractical and time-consuming, resulting in increased costs. In contrast, desiccant dehumidifiers support continuous blasting and painting in a single operation, offering an economical solution for power plants.

Their benefits also extend to preserving electromechanical equipment by ensuring its longevity and performance. Additionally, they assist in concrete drying and help maintain controlled relative humidity in control rooms, preventing equipment malfunctions and supporting optimal operations.

With these advantages, the deployment of desiccant dehumidifiers across industrial facilities is essential. By addressing moisture-related threats, they extend the life of the coating system, support the efficiency of related processes, and ultimately boost the productivity of the plant.

Authored by, Atul Bansal, Chief Operating Officer, Technical Drying Services

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Godrej Motor Solutions targets ₹1,000 crore revenue by FY28, driven by EV demand, export growth, and advanced manufacturing at the Pune facility.

Godrej Enterprises Group’s Motor Solutions business aims to generate ₹1,000 crore in FY2027-28, with exports accounting for 20% of total income. The aim for FY2025-26 is ₹750 crore, driven by demand for electric vehicles (EVs), HVAC applications, pump applications, and actuators in domestic and international markets.

R&D efforts and the use of new technology are helping the organisation improve its manufacturing skills. The company built a new assembly line for EV motor components to accommodate expansion in India and export markets like the United States and Europe. AIDA Japan is installing a high-precision lamination punching line to address the demand for ultra-thin laminations in the electric vehicle, aerospace, and automation industries.

Xercsis Marker, Executive Vice President & Head of the Motor Solutions Business at Godrej Enterprises Group, stated, “We are strengthening our manufacturing capabilities through significant R&D investments and advanced technology adoption. We continue to invest in technology and capacity to serve identified growth sectors like EV, automation, actuators, pumps, etc. while advancing innovations in motor design to reduce reliance on rare-earth materials.”

In the Indian market, Godrej Motor Solutions accounts for 60% of the hermetic motors for refrigeration and air-conditioning. The company has produced fully assembled motors for the US off-road EV market and intends to manufacture motors for a German company with compatible controller solutions.

To reduce dependency on rare-earth magnets and increase efficiency, investments have been made in motor technologies such as switched reluctance and synchronous reluctance motors.

The manufacturing facility can produce over 6 million motors per year and offers more than 300 customised SKUs. It holds IGBC Platinum and GreenCo Platinum Plus certifications, produces zero waste to landfill, is water-positive, and recycles 80% of finished goods packaging.

The institution sits on a 36-acre complex near Shindewadi, Pune. Most suppliers are located within a 100-kilometre radius.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

BEML and DRDO have signed agreements to produce support vehicles and transport systems for the Arjun Main Battle Tank.

BEML Limited, a “Schedule A” public sector firm under the Ministry of Defence, has signed three key licence agreements with the DRDO’s Vehicles Research & Development Establishment (VRDE). These agreements will allow BEML to build advanced support vehicles for the Indian Army’s Armoured Corps on a local scale, hence enhancing indigenous capabilities under the Aatmanirbhar Bharat plan.

BEML will produce three critical systems to support the Arjun Main Battle Tank (MBT) under the terms of the agreements. These include the Unit Maintenance Vehicle (UMV) for on-the-spot repairs and recovery during operations, as well as the Unit Repair Vehicle (URV) for more in-depth technical servicing in forward locations. Both vehicles are critical to providing minimal downtime and optimum operating effectiveness for armoured units.

BEML will also manufacture a heavy-duty trailer with hydraulic suspension and steerable axles, capable of transporting 70-tonne tanks and significant military equipment. This trailer is designed to handle a variety of terrains, greatly enhancing field logistics and mobility.

The licences were officially signed at VRDE’s Ahmednagar site. Dr Samir V. Kamat, Secretary of Defence R&D and Chairman of DRDO attended the ceremony, as did Sanjay Som, BEML’s Director of Mining & Construction. The collaboration emphasises BEML’s rising significance in defence production, as well as its developing partnership with DRDO to boost national security.

Commenting on the partnership, Shantanu Roy, CMD of BEML, stated, “This collaboration marks a significant step in enhancing the operational capabilities of the Indian Army through indigenous solutions, fully aligned with the government’s Aatmanirbhar Bharat vision.”

The agreements aim to boost self-reliant defence production and improve mobility support for India’s armoured forces.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.