BEML and DRDO have signed agreements to produce support vehicles and transport systems for the Arjun Main Battle Tank.

BEML Limited, a “Schedule A” public sector firm under the Ministry of Defence, has signed three key licence agreements with the DRDO’s Vehicles Research & Development Establishment (VRDE). These agreements will allow BEML to build advanced support vehicles for the Indian Army’s Armoured Corps on a local scale, hence enhancing indigenous capabilities under the Aatmanirbhar Bharat plan.

BEML will produce three critical systems to support the Arjun Main Battle Tank (MBT) under the terms of the agreements. These include the Unit Maintenance Vehicle (UMV) for on-the-spot repairs and recovery during operations, as well as the Unit Repair Vehicle (URV) for more in-depth technical servicing in forward locations. Both vehicles are critical to providing minimal downtime and optimum operating effectiveness for armoured units.

BEML will also manufacture a heavy-duty trailer with hydraulic suspension and steerable axles, capable of transporting 70-tonne tanks and significant military equipment. This trailer is designed to handle a variety of terrains, greatly enhancing field logistics and mobility.

The licences were officially signed at VRDE’s Ahmednagar site. Dr Samir V. Kamat, Secretary of Defence R&D and Chairman of DRDO attended the ceremony, as did Sanjay Som, BEML’s Director of Mining & Construction. The collaboration emphasises BEML’s rising significance in defence production, as well as its developing partnership with DRDO to boost national security.

Commenting on the partnership, Shantanu Roy, CMD of BEML, stated, “This collaboration marks a significant step in enhancing the operational capabilities of the Indian Army through indigenous solutions, fully aligned with the government’s Aatmanirbhar Bharat vision.”

The agreements aim to boost self-reliant defence production and improve mobility support for India’s armoured forces.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Tata Electronics and BEL have signed an MoU to develop indigenous semiconductor and electronics solutions for India.

Tata Electronics, a major player in India’s electronics manufacturing sector, has inked an MoU with Bharat Electronics Limited (BEL), a Navratna PSU under the Ministry of Defence. This strategic alliance intends to accelerate the development of indigenous semiconductor and electronics solutions, thereby helping the Indian government’s goal of self-reliance in sophisticated technologies.

The agreement was signed by Dr Randhir Thakur, CEO and Managing Director of Tata Electronics, and Shri Manoj Jain, Chairman and Managing Director of BEL.

Under this arrangement, the two companies will look at the potential in semiconductor fabrication (Fab), outsourced semiconductor assembly and testing (OSAT), and design services. The emphasis will be on addressing BEL’s current and future requirements in areas such as microcontrollers (MCUs), systems on chip (SoCs), monolithic microwave integrated circuits (MMICs), and processors.

Tata Electronics and BEL will also collaborate on developing optimal production solutions through information exchange, best practices, and resource sharing. This collaboration is an important step towards boosting India’s domestic electronics ecosystem and improving capabilities in defence and high-tech manufacturing.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Fronius marks 20 years of its Cold Metal Transfer (CMT) technology, a welding innovation known for low heat input, high precision, and versatile industrial use since 2005.

Fronius, a global welding technology leader, is marking the 20th anniversary of its groundbreaking Cold Metal Transfer (CMT) method. CMT, which was introduced in 2005, has redefined welding standards by providing superior control, stability, and little heat input, resulting in clean, high-quality welds with no spatter.

CMT is based on a reversing wire movement that allows for regulated droplet detachment, resulting in a steady arc with minimal heat input. The result is flawless, practically spatter-free welding with minimal deformation, even on thin sheets (0.3 mm) and temperature-sensitive materials. It also facilitates the bonding of different materials like galvanised steel and aluminium.

CMT is widely used across industries. In the automotive sector, it welds thin sheets and lightweight materials like aluminium. In aerospace, it handles high-strength, lightweight materials. The electronics industry uses it for precise brazing, and it also supports 3D printing applications.

Fronius’ WireSense system, powered by CMT, enhances robotic welding with intelligent air gap and edge detection. The welding wire acts as a sensor, optimising weld positioning in real-time, reducing material use and rework.

Fronius continues to refine CMT technology, offering specialised variants like CMT Mix, CMT Cycle Step, CMT Cladding, and CMT Braze. LaserHybrid CMT merges laser welding and CMT for high-speed, high-quality results, particularly on high-strength steel and aluminium.

CMT Additive Pro is the recent development, designed specifically for metal 3D printing, allowing for more advanced additive manufacturing capabilities. CMT is compatible with all intelligent Fronius equipment and can be simply retrofitted, ensuring future-proof welding solutions.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

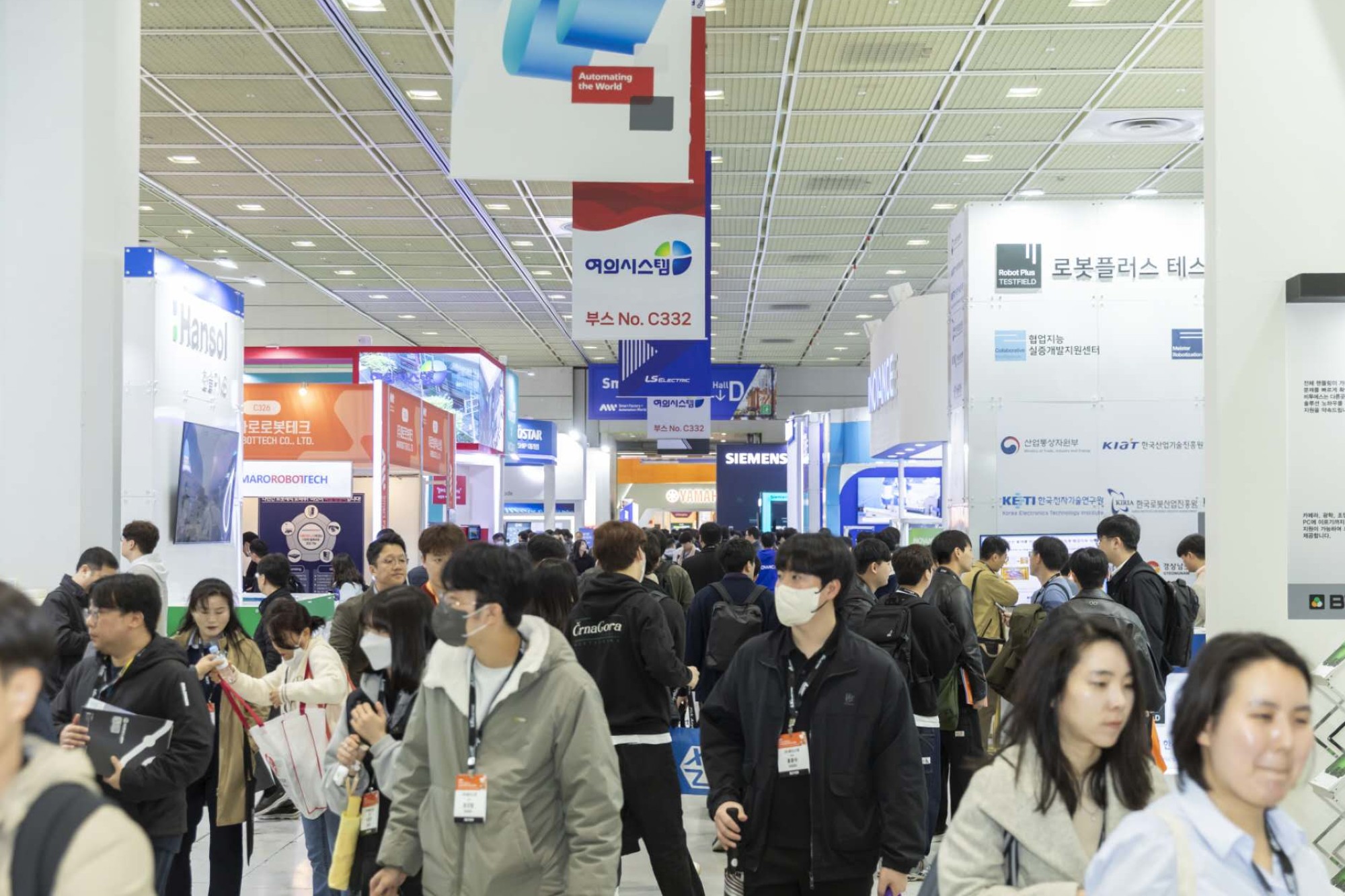

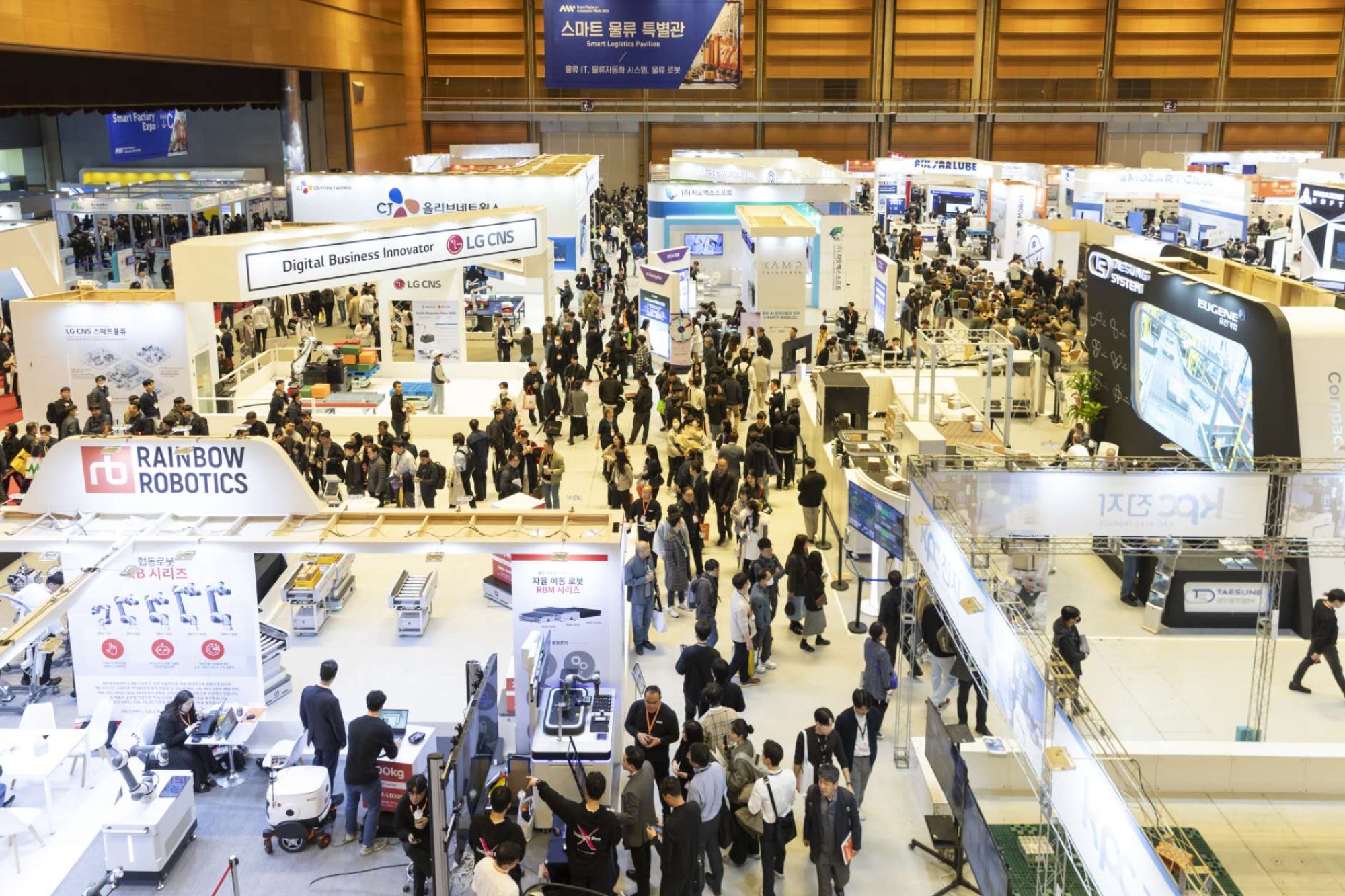

AW 2025, Asia’s largest smart factory and automation expo, took place at COEX, South Korea, spotlighting the latest in manufacturing technology and innovation.

AW 2025, Asia’s premier Smart Factory and Automation Expo, was held at the COEX site in Korea on its largest scale ever. The event, titled “Automation to Autonomy”, took place from March 12 to 14, covering all COEX exhibition halls and highlighting the newest in smart manufacturing technology.

AW 2025, Korea’s premier industrial fair, displayed cutting-edge solutions in factory automation, big data, artificial intelligence (AI), cloud computing, and industrial robotics. This year’s edition included over 400 exhibitors across 2,200 booths and attracted nearly 70,000 people from all around the world.

The show floor featured cutting-edge advancements from top worldwide automation firms such as Rockwell, Schneider Electric, and HD Hyundai Robotics. Hyundai AutoEver and Hyundai Glovis, both part of the Hyundai Motor Group, made their event debuts, showcasing smart logistics and autonomous vehicle technologies.

The expo offered enriching activities; over 150 sessions were held at more than 25 specialised manufacturing seminars, including the AI Autonomous Manufacturing Conference, the Korea-China-Vietnam Robot Convergence Technology Conference, and IIoT Innovation Day.

To enhance visitor engagement, the “AW Booth Docent Tour” offered guided walkthroughs with expert commentary, while the newly introduced “AW Open Innovation Round” fostered collaboration between dynamic startups and established investors.

Lee Dong-gi, President of COEX, commented, “AW 2025 is the definitive gathering for the global digital manufacturing community. We hope this event serves as a platform for exhibitors and buyers alike to accelerate digital transformation across the manufacturing landscape.”

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

India revises SEZ rules to boost chip and electronics manufacturing, cutting land requirements and easing norms to attract high-tech investments.

The Indian government has notified major revisions to the Special Economic Zones (SEZ) Rules, 2006, aimed at attracting high-tech investments and establishing a sustainable manufacturing base. The reforms are designed to satisfy the specific needs of semiconductor and electronics component manufacturing, which is capital-intensive, import-dependent, and characterised by protracted gestation periods.

A crucial aspect of the reform is the lowering of the minimum acre requirement for SEZs dedicated solely to semiconductor and electronics component manufacture. The criteria have been reduced from 50 hectares to 10 hectares, greatly cutting the entry hurdle for establishing such ventures. This shift is expected to accelerate the creation of innovative manufacturing facilities around the country.

The government has revised the law requiring encumbrance-free property to make SEZ construction easier. The Board of Approval can now enable land mortgaged or leased to the Central or State Governments or their authorised agencies to be utilised for SEZ purposes. This flexibility is likely to release more land parcels and speed up project approvals.

In addition to land-related reforms, the government has made targeted improvements to other essential regulations. Rule 53 has been revised to include free-of-cost goods—both received and supplied—in the computation of Net Foreign Exchange (NFE), using appropriate customs valuation methodologies. Rule 18 now allows SEZ units in the semiconductor and electronics component sectors to sell within the Domestic Tariff Area (DTA) after paying the appropriate charges. These modifications are intended to improve operational flexibility and the simplicity of doing business for high-technology enterprises.

The Department of Commerce officially announced these revisions on June 3, 2025, and they have already sparked fresh investments. The Board of Approval has cleared two significant proposals under the amended regulations.

Micron Semiconductor Technology India Pvt Ltd (MSTI) plans to establish a 37.64-hectare semiconductor SEZ in Sanand, Gujarat, with an estimated investment of ₹13,000 crore. Hubballi Durable Goods Cluster Pvt Ltd, part of the Aequs Group, would build an SEZ for electronics component manufacture in Dharwad, Karnataka, covering 11.55 hectares with a ₹100 crore investment.

These measures, taken together, represent a critical step towards India’s development of a world-class semiconductor and electronic manufacturing ecosystem. They are consistent with the government’s broader economic agenda under the “Make in India” and “Atmanirbhar Bharat” initiatives, which aim to develop indigenous capabilities, reduce import dependence, and create high-skilled jobs.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

OEMs are turning to digital platforms and region-specific strategies to achieve efficient consumption, reduce emissions, and meet global standards, driven by rising energy costs and evolving regulations. G Balaji, SVP of Energy Industries at ABB India, discusses the company’s focus on changing energy management into a strategic function that enhances efficiency and sustainability.

How is ABB helping global original equipment manufacturers (OEMs) adopt advanced energy management systems?

We focus on transforming energy management into a strategic function that enhances efficiency and sustainability. Our ABB Ability OPTIMAX solution exemplifies this by tackling the diverse energy management challenges that industrial enterprises and energy providers face in the oil and gas, chemicals and refining, water, and power sectors.

OPTIMAX® enhances energy by optimising energy usage, reducing emissions, and improving overall energy efficiency. It provides real-time visibility into consumption patterns, enabling data-driven decisions to reduce costs and carbon footprints. Furthermore, our monitoring and reporting tools ensure compliance with standards like ISO 50001, highlighting opportunities for energy efficiency improvements. By integrating solutions engineered to outperform, we help our consumers meet domestic and global energy demands efficiently.

With the push for localisation and regional manufacturing hubs, how is ABB addressing energy infrastructure disparities between developed and emerging markets?

We are implementing targeted strategies to address diverse energy infrastructure needs across regions. We do not believe in a one-size-fits-all approach. Instead, we localise production, design adaptable solutions, and empower communities to ensure developed and emerging markets advance in energy transition at their own pace.

In India, we support the natural gas expansion goals through automation, SCADA (Supervisory Control and Data Acquisition) systems, which are components of our broader automation and industrial digitalisation solutions, as well as control systems for CGD networks. We support power generation and utilities with Automatic Generation Control (AGC) solutions, which optimise generator operations to enhance the efficiency and reliability of power plants.

In Europe, we support the transition to a carbon-neutral economy by enhancing electric vehicle (EV) infrastructure and promoting the integration of renewable energy sources. This tailored approach enables us to effectively navigate regional requirements, driving sustainable energy solutions that respect the unique dynamics of each market.

How is ABB integrating digital technologies into its energy management solutions for globally distributed original equipment manufacturer (OEM) facilities?

Our energy management solutions are largely based on digitalisation. We enable OEMs to leverage energy as a strategic asset by utilising connected platforms that provide real-time insights, predictive analytics, and actionable intelligence. ABB Ability provides a simple and cost-effective solution for energy and power quality monitoring, offering remote access to plant data and asset monitoring to enhance equipment reliability and availability. This platform integrates data from sensors, controllers, and cloud analytics, delivering a unified operational view.

Additionally, predictive diagnostics enable us to anticipate failures before they occur, while remote monitoring allows centralised teams to manage multiple plants with minimal physical intervention. This is crucial for companies with global operations, where standardising energy practices across diverse facilities can lead to significant efficiency gains. Our technologies, including digital twins, AI-driven forecasting, and remote troubleshooting, enable industries to utilise energy data for enhanced efficiency and cleaner operations.

How are ABB’s energy management solutions helping OEMs reduce their energy usage while maintaining cost efficiency and compliance?

Operating efficiently and sustainably is imperative in today’s rising energy costs and stringent carbon regulations. At ABB, we engineer energy management solutions that help OEMs like yours balance operational efficiency, meet regulatory requirements, and achieve meaningful cost savings.

The ABB Ability Energy Manager digital platforms help monitor energy consumption and CO₂ footprint. This digital solution enables faster, more informed decision-making through data insights, providing OEMs with real-time visibility into energy use across their processes and equipment. This transparency enables data-driven decisions to reduce peak demand and optimise load schedules, thereby eliminating unnecessary energy waste and lowering utility bills and emissions. What sets us apart at ABB is our ability to combine deep domain expertise with global standards and local execution. We don’t just provide technology — we partner with companies as long-term energy allies, supporting their transition to a lower-carbon, more cost-efficient future. Our commitment goes beyond products; we offer strategic energy advisory that empowers OEMs to tackle current and future regulatory challenges.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Payal Industrial Park (PIP) showcased India’s chemical manufacturing strength at Chemspec Europe 2025, drawing global investor interest with its advanced Gujarat infrastructure.

Payal Industrial Park (PIP), the largest private industrial park in Gujarat’s PCPIR region, represented India at the Chemspec Europe 2025 exhibition in Koelnmesse, Germany. The event is Europe’s biggest exhibition for fine and specialty chemicals, attracting over 410 exhibitors and thousands of professionals from 24 countries.

PIP, one of the few Indian industrial parks at the event, highlighted India’s strengths as a manufacturing hub with advanced infrastructure, including plug-and-play facilities, a Central Effluent Treatment Plant (CETP), and access to Dahej Port.

Virender Kumar, Vice President of Marketing, PIP, stated “Chemspec Europe 2025 was an excellent platform to put India’s industrial infrastructure on the world map. The level of engagement and the earnestness of discussions among potential partners and investors were something we were very pleased with. The participation reiterates that India is now being considered as an emerging centre of sustainable and efficient chemical manufacturing.”

Key themes discussed during the two-day event included sustainable manufacturing, bioeconomy innovation, and digital transformation in the chemical sector. PIP’s involvement aligned with India’s economic goals of “Make in India” and “Atmanirbhar Bharat,” which aim to increase domestic output and attract foreign investment.

PIP’s participation in Chemspec Europe 2025 reaffirmed its objective of becoming a preferred destination for international industrial investments in South Asia.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Inovance, a global leader in industrial automation, reported a strong performance in 2024 with USD 5.2 billion in revenue.

Inovance, a global leader in industrial automation, has announced exceptional results for the year 2024, achieving USD 5.2 billion in global revenue, representing a 22% year-on-year growth. This milestone underscores the company’s commitment to delivering innovative, reliable automation solutions to customers worldwide.

The growth led by strong performance in general industrial automation, where Inovance’s broad portfolio of products—ranging from AC drives and servo systems to motion control and PLCs—continues to support customers in diverse manufacturing sectors with advanced automation technologies.

Inovance also made a significant investment in research & development, allocating USD 442 million, or 8.5% of total revenue, to drive continuous innovation and development of next-generation products and solutions.

Strengthening Presence in India

India continues to play a vital role in Inovance’s global expansion strategy. Inovance Technology India now employs over 200 professionals and operates through a strong network of five branch offices located in Noida, Mumbai, Ahmedabad, Hyderabad, and Surat. The company runs a dedicated service and repair centre in Surat, ensuring timely support and maintenance for customers across the region.

The company’s head office is located in Chennai, with a manufacturing facility situated at MM Nagar, Chennai, supporting local operations and further strengthening Inovance’s presence in the Indian market.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

“Building a strong environment is essential for any organisation and must include women and diverse employees. McKinsey & Company found that gender-diverse leadership teams are 21% more likely to achieve higher profitability. At the same time, the Institute for Women’s Policy Research reports that women in male-dominated industries face 35% more harassment.”

Dr Madhur Saxena, Corporate Head – Health, Safety and Sustainability at Deepak Group Co, in conversation with Dr Megha Bansal, Chief Skilling Officer WIMA & Leadership Coach, shares how Behaviour-Based Safety (BBS) initiatives are addressing the specific needs of women and diverse employees. A holistic approach that includes leadership commitment, ongoing training, and open communication is crucial.

In your experience, what are the most critical steps in building a strong safety culture in manufacturing setups, and how can organisations ensure this culture is inclusive for women and diverse employees?

Building a strong safety culture in manufacturing setups requires a multi-faceted approach. We at Deepak Group, strongly believe that each of us is a Safety Leader and is empowered to pro-actively own and drive a safety-first culture. It is this mindset and confidence of the workforce that is what makes an organisation successfully build a robust safety culture. In my experience as an expert across the industry, over the years, I would say that at the core are five critical steps that organisations should take:

1. Leadership commitment and accountability

A robust safety culture starts with leadership. In Organisations where the senior leaders demonstrate unwavering commitment to safety, both in their actions and words, safety organically becomes a part of the shop floor mindset and culture. When leadership is actively involved and holds itself accountable for safety outcomes, it sets the tone for the rest of the organisation and leads to every employee making safety a priority not only for themselves but also for the organisation.

2. Training and Re-Training

Manufacturing environments are fast paced, so training should be regularly updated to cover new technologies, processes, and risks. Our experience has shown that training programs will fail to deliver results on the shop floor if they are not aligned with the actual on-ground training needs of the fast-evolving workforce. Smart and progressive organisations regularly invest in robust training needs identification program that takes input from the shop floor, and various data points like unsafe acts, unsafe conditions, near misses, and past incidents. The impact of this consistent and rigorous focus on training has helped many companies reduce accidents by up to 60%.

3. Open Communication

“Good News is No News, No News is Bad News, and Bad News is Good News” in the world of safety improvement. If an employee is coming up to report any bad news like an unsafe act, or a safety violation then it is a good sign for the company. As this means that the organisation has been able to build a culture of safety, trust and confidence in their workforce to have open communication, be it employees, or even contractual workforce. It is imperative that people in a manufacturing ecosystem are comfortable to share and report information and incidents to bring improvement in leading & lagging indicators of safety

4. Employee Participation

The key to driving a Safety-First organisation is to have engaged and active Employee participation, with no discrimination or biases, where each one believes that they are owners of their own safety. “Safety is not something which can be added to the Job, it’s the way to do the Job”. So, we have to understand that only when the teams on-ground are involved in shaping the safety culture, they will be able to own safety outcomes, and the organisation will be able to see the safety culture implemented.

5. Reward and Progressive Disciplinary Matrix

Rewards play a crucial role in motivating employees to achieve their tasks efficiently. However, it’s important to strike a balance, as excessive rewards can undermine the safety culture. When employees become overly dependent on rewards, they may struggle to perform tasks without them. Therefore, a well-structured reward system should be complemented by a progressive disciplinary matrix to address wilful violations, ensuring a safe and productive work environment.

Safety Culture of Diversity, Equity & Inclusion

While building a strong safety culture, it is equally important to ensure that the safety culture is inclusive, particularly for women and diverse employees. While the industry has been working consistently on improving and strengthening measures for women safety, it is still a concern across India Inc. A few years back, The Institute for Women’s Policy Research found that women in male-dominated industries, such as manufacturing, are 35% more likely to experience harassment. The industry has come a long way since then with many focussed and committed measure to adopting Zero Tolerance for Harassment and Discrimination by addressing gender-specific needs, promoting diverse leadership in safety roles, and ensuring inclusive safety practices.

It is the need of the hour for Organizations to ensure that they create an environment where safety is a shared responsibility and everyone feels protected and valued. This not only improves safety outcomes but also leads to higher employee satisfaction and overall organizational success.

The aim is to make So we need to take care at both fronts.

While developing an inclusive safety culture we also discuss about “Care”. We do BBS (Behaviour Based Safety) because we care and the care no one can understand better than Women. While addressing our program we need to take care of their specific needs of women and Diverse employees at shop floor. Some time with Specific PPE’s, Specific Training and specially Zero-Tolerance Policy for Harassment and Discrimination.

Building a strong safety culture in manufacturing requires a holistic approach, where leadership commitment, ongoing training, open communication, and employee involvement are all crucial components. At the same time, it’s vital that this culture is inclusive for women and diverse employees. By addressing gender-specific needs, promoting diverse leadership in safety roles, and ensuring inclusive safety practices, organizations can create an environment where safety is a shared responsibility, and everyone feels protected and valued. This not only improves safety outcomes but also leads to higher employee satisfaction and overall organizational success.

What specific safety challenges may women face on the shop floor, and how can organisations redesign workplace safety protocols to address gender-specific concerns?

The Manufacturing sector over the last few decades has seen tremendous transformation with state-of-the-art plants, technologies and infrastructure combined with employee-centric policies and robust ecosystems to support diversity, equity and inclusion. This is also visible in the safety space, and more so with much care when it comes to women in manufacturing.

Women in manufacturing environment often face unique safety challenges, if safety protocols are not designed with gender-specific needs in mind. Addressing these challenges is crucial for creating an equitable and safe workplace for all employees.

Industry reports show that women at workplace are 2.5 times more likely to experience discomfort or safety hazards when using ill-fitting PPE. Standard PPE, such as safety gloves, helmets, eye protection, and body suits, is often designed primarily for male workers, leading to discomfort or ineffective protection for women. This can result in increased risk of injury or inefficiencies in the job.

Ergonomically designed PPE specifically for women that fits to women’s body types are now being designed and customised by companies along with proper protection and comfort to solve the problem. Similarly, safety gloves, Helmets and protective clothing with better dexterity and work boots designed for women’s foot shapes are being made to reduce discomfort and improve overall safety.

2. Shopfloor Safety for women

Women in manufacturing may sometimes experience higher rates of musculoskeletal disorders (MSDs) compared to men, often due to handling heavy materials and working in physically demanding environments. Women generally have lower muscle mass and different biomechanical needs compared to men, which can increase the risk of strain or injury from repetitive tasks or lifting.

To mitigate this, Job rotation at a frequent interval has minimized the risk of repetitive motion injuries.

3. Safe Working Environment for Women

Women in male-dominated manufacturing environments may sometime experience harassment, discrimination, or even physical threats, which can undermine their physical and psychological safety. This often discourages women from speaking up about safety concerns, potentially leading to underreporting of hazards or unsafe practices.

Every company should have a Zero-Tolerance Policy and strict enforcement, regular training on harassment prevention and Clear, accessible and confidential channels reporting mechanism to ensure a safe working environment for all women and diverse gender employees.

All employees irrespective of Race, Gender, Cast and Religion, should feel safe from any inappropriate and unwelcome behaviour.

We should Foster a safety culture where all employees’ concerns are valued, regardless of gender. Train managers and supervisors to actively listen and address safety concerns raised by women in the workplace. Regular Feedback and anonymous Surveys is the most important way to gauge employees’ concerns.

By addressing these gender-specific safety challenges, organizations can create a more inclusive and safer workplace for all employees, particularly women. Redesigning PPE, modifying work tasks, addressing harassment, and providing supportive policies for pregnant workers are key steps to ensuring safety and reducing risks. It is important to consider the diverse needs of the workforce in the development of safety protocols and workplace design to promote an environment where everyone can thrive.

How can the principles of process safety be adapted to ensure safer working environments that attract and retain more women in technical and operational roles?

A study by McKinsey & Company highlights that companies with gender-diverse leadership teams are 21% more likely to outperform on profitability.

A critical component of process safety is ensuring that workers feel secure in their environment, both physically and emotionally.

Regular training on harassment and inclusion addresses safety protocols and prevention and fosters a respectful workplace. Empower employees to report inappropriate behaviour and ensure no retribution risks.

Diversity and inclusion in safety leadership positions, especially in safety-related roles, can reinforce the importance of inclusion in safety culture. Women in leadership roles can help build trust and improve employee safety outcomes.

Mentorship and career development in process safety should focus on immediate safety measures and foster career growth and development opportunities for women in technical and operational roles.

Women, particularly those in technical and operational roles, may require more flexibility to balance work and personal life. Offering flexible work policies that support work-life balance can help attract and retain women in safety-critical roles, reducing burnout and increasing job satisfaction.

To attract women to technical roles, it is important to create an inclusive safety training environment where everyone feels supported, regardless of gender.

Ensure that safety training materials and programs are gender-neutral and represent the diverse workforce.

Representation matters in process safety roles. Organisations should actively promote female role models in safety leadership positions to attract and retain more women.

How does behaviour-based safety contribute to employee well-being and workplace trust? Are any behavioural insights specific to improving safety engagement among underrepresented groups like women?

Behaviour-based safety (BBS) is a proactive strategy that focuses on reinforcing safe behaviours in the workplace. An inclusive BBS approach is crucial for engaging underrepresented groups, particularly women, who may face unique challenges on the shop floor.

BBS encourages employees to take ownership of their safety and that of their colleagues, fostering a greater sense of control and responsibility. Continuous feedback on safety practices fosters trust and ensures that concerns are addressed.

Positive reinforcement: BBS fosters a supportive environment that values employees, thereby boosting morale and job satisfaction. This is particularly important for women in male-dominated industries, who may hesitate to report safety concerns. Tailored strategies, like regular check-ins and anonymous reporting, can help ensure their voices are heard.

Focusing on “CARE”: BBS programs should include women in leadership roles and involve them in developing safety initiatives. Creating a peer network can also support and empower women, promoting collective responsibility for safety. Addressing unique concerns, such as ergonomics and the use of appropriate personal protective equipment (PPE), and soliciting feedback from women will enhance the effectiveness of safety programs.

How do you view the link between safety, sustainability, and social inclusion in the context of responsible manufacturing? Can safety culture contribute to broader ESG goals?

The link between safety, sustainability, and social inclusion is integral to responsible manufacturing, where companies strive to have a positive impact on the environment, society, and the economy. These three pillars—safety, sustainability, and social inclusion—are deeply interconnected, and the safety culture can advance an organisation’s broader Environmental, Social, and Governance (ESG) goals.

Safety is the cornerstone of any responsible manufacturing operation. Without a strong safety culture, preventable accidents, injuries, and inefficiencies may undermine efforts toward sustainability and social inclusion. A well-established safety culture directly impacts worker well-being, operational efficiency, and the company’s reputation. Effective safety practices often overlap with environmental considerations. For example, safe handling of hazardous materials, preventing spills or accidents and ensuring proper waste management practices are essential to avoid environmental contamination. A strong safety culture helps mitigate risks that could impact the environment, contributing to more sustainable operational practices.

Sustainability in manufacturing means reducing environmental impact while fostering an operational culture that benefits employees, communities, and the planet.

Safety is essential for achieving sustainability goals. By incorporating environmental safety protocols into operations, manufacturing companies can reduce their ecological footprint and enhance sustainability. Well-maintained machinery and well-trained workers lead to less waste, lower energy consumption, and greater resource efficiency.

A safety-focused workplace improves employee health, productivity, and satisfaction and contributes to social well-being, particularly for marginalised groups. Creating safe environments demonstrates social responsibility.

A strong safety culture promotes social inclusion by fostering trust among diverse employees and ensuring everyone feels valued. It also supports Environmental, Social, and Governance (ESG) goals, which are increasingly important to stakeholders. Safety minimizes environmental risks and ensures sustainable practices are executed safely while addressing issues like workplace harassment and discrimination.

Moreover, safety culture reflects a company’s commitment to transparency and ethical practices, leading to better governance and trust with stakeholders, including regulators and investors.

What role does leadership play in embedding a safety-first mindset while promoting diversity, equity, and inclusion (DEI) in manufacturing organisations?

Leadership in manufacturing organisations must prioritise a safety-first mindset while promoting Diversity, Equity, and Inclusion (DEI). Effective leaders set the tone for cultural change, ensuring that safety and DEI are integral to the organisation. They must cultivate a safety-first approach, personally committing to safety protocols and clearly communicating expectations to the entire workforce.

Leaders should advocate for Diversity, Equity, and Inclusion (DEI) by establishing a clear vision and promoting diversity in leadership and decision-making processes.

Leaders can create a cohesive culture where safety and DEI coexist by emphasising safety and inclusive behaviours, such as encouraging diverse contributions to safety discussions. Comprehensive safety policies should address physical, mental, and emotional well-being, ensuring inclusivity for all employees.

Leaders should foster open communication by holding regular listening sessions, empowering employees to discuss safety and diversity, equity, and inclusion (DEI) concerns. Tracking safety performance and setting measurable goals for improvement are essential, as is holding the organisation accountable for its DEI objectives.

Safety and DEI must be addressed holistically; physical safety also includes emotional and social well-being, particularly for women and minorities. Leaders can integrate sustainability principles into their safety and diversity, equity, and inclusion (DEI) efforts, aiming for long-term improvements in workplace conditions and representation.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Continental is investing ₹100 crore to expand PLT tire production in India, focusing on SUV and UV segments to meet growing local demand.

Continental, a leading global premium tire manufacturer, has announced a strategic investment to strengthen its presence in India’s Passenger Car and Light Truck (PLT) tire segment. The company plans to invest approximately INR 100 crore (EUR 10.5 million) to enhance its manufacturing capabilities and expand its PLT tire product range in the country.

This investment reflects Continental’s commitment to developing tires specifically tailored for Indian driving conditions, with a strong focus on performance and premium quality. It also reinforces the company’s dedication to shaping the future of mobility in India through innovation, local manufacturing, and customer-centric solutions aimed at driving sustainable growth.

Samir Gupta, Managing Director of Continental Tires India stated, “With our ‘in the market, for the market’ approach, we’re aligning our portfolio to reflect the evolving lifestyle needs of Indian drivers—from daily commutes and long-distance travel to changing expectations around comfort, safety, and convenience.”

As India undergoes rapid infrastructure development and consumer preferences shift—particularly with the surge in demand for utility vehicles (UVs)—Continental sees significant growth opportunities in larger-inch and Ultra Ultra High Performance (UUHP) tires. These are designed for SUVs, 4x4s, and sporty vehicles, aligning well with current market trends.

Continental also plans to expand its all-terrain offerings with the launch of the CrossContact AT2 later this year.

Committed to long-term growth in the region, Continental aims to further solidify its position as a trusted premium tire brand in India. The company manages sales and distribution from its headquarters in Faridabad, manufactures PLT tires in Modipuram, Meerut (Uttar Pradesh), operates over 200 brand stores across the country, and has recently opened an IT hub in Bengaluru.

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.