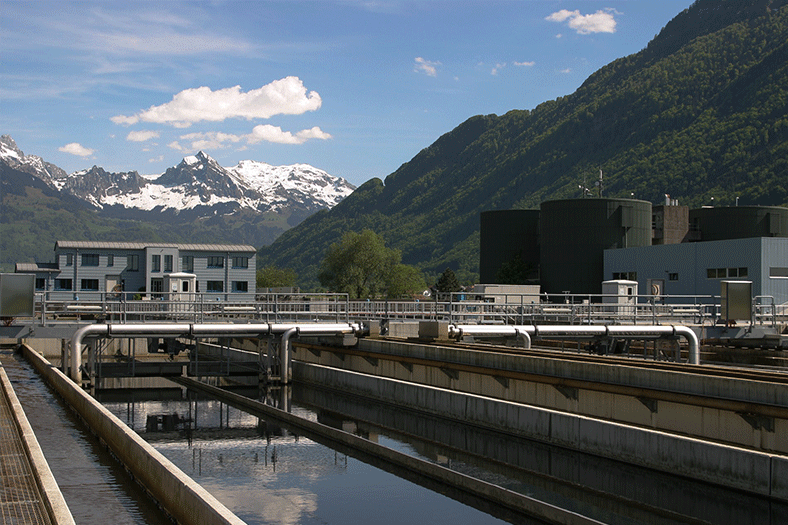

Deploying technology for increased access to recycled wastewater

By OEM Update Editorial May 7, 2020 4:43 pm IST

Industry leaders explore ideas to recycle and reuse the wastewater generated at manufacturing facilities and the plant level by using revolutionary technologies and processes.

Wastewater management is an important practice for a country like India that has a vast population and limited access to fresh water sources. Effective wastewater management can serve as a tool to cut down the water stress within a community and safeguard vital resources from pollution and environmental contamination. With World Water Day having been celebrated on 22nd March 2020, the conversation about water conservation as well as environmental impact, natural resources and climate change intensifies, and companies in various industries are in the frontline of finding “out-of-the-box” solutions to treat their wastewater and industrial discharge.

Managing wastewater at facility

Wastewater treatment is the process of removing contaminants from water discharged from domestic, industrial or commercial premises as well as surface run-off. Wastewater treatment typically utilises mechanical, biological, and chemical processes to remove these contaminants.

Grundfos supplies a whole range of components for a complete mechanical, biological, and chemical wastewater treatment plant. Sanjeev Sirsi, Associate Vice President – Water Utility, Grundfos Pumps India Pvt. Ltd., says “With sustainability as a core element of our ethos, our facilities are designed to minimise their impact on the environment. Grundfos India’s Chennai production unit is a zero liquid discharge plant with in-house sewage treatment and effluent treatment plants. The domestic wastewater generated in the facility is treated at our sewage treatment plant and the treated water is used for gardening and landscaping activities. The industrial wastewater is treated at our effluent treatment unit and is reused for processes at the plant.”

He adds, “Our Chennai facility is the country’s first LEED-certified commercial gold-rated green building certified by US – Green Building Council (USGBC) in 2005. This is an energy-efficient building, with rainwater harvesting and solar collectors that generate about 208 MWh from our rooftop solar panels that are used in our plant contributing to a green cause. Subsequently in February 2020, the factory upgraded its certification from USGBC, making the entire Grundfos Chennai site as LEED Platinum.”

Whereas, Adani Dahanu Thermal Power Plant’s spokesperson says, “Our 500 MW Adani Dahanu Thermal Power Station at Dahanu aims at zero discharge by optimising water consumption and recycle/reuse. “We have taken this initiative right at the conceptual stage. As condenser cooling consumes the maximum sweet water, ADTPS substituted sweet water by seawater in the design itself and reduced the sweet water requirement by 90 percent. All of the industrial and domestic wastewater generated is recycled after treatments like clariflocuulation, neutralisation, and aeration and is used for plantation, equipment cooling, and ash disposal.”

The diminishing water reserves and cumulative water costs have stimulated the reuse of wastewater, including those generated at the industries. This has further compelled the industries to re-evaluate their wastewater management techniques. A decentralised wastewater treatment involves a variety of approaches for collection, treatment, and reuse of the wastewater generated. Elaborating on this, Meenu Singhal, Vice President – Industry Business, Schneider Electric India, says, “As part of permanent infrastructure, the decentralised system provides a range of treatment options from simple to complex approaches. Sustainable and cost-effective, a decentralised wastewater treatment system is apt for India as it works well in rural, suburban and urban settings. This also offers a long-term solution for water management if properly planned, operated, and maintained.”

Recycling and filtering wastewater generated at the plant level

Industrial wastewater generates water with large environmental impacts if they are not correctly treated. To limit these impacts, there is strict legislation that penalises illegal dumping of poorly treated effluents. Industrial wastewater has a higher risk factor than urban wastewater; it is due to the chemical products used in the industrial manufacturing processes and the diversity of its compositions.

The concept of industrial wastewater treatment has been changing. Nowadays it is intended to go further, maximising the efficiency of the process through the recycling and reuse of treated water, generation of energy in the purification process, recovery of nutrients like nitrogen or phosphorus, use of sewage sludge as compost and/or even manufacture of bioplastics.

On this note, Sirsi feels, “Reusing treated water is the best way to boost the efficiency of purification process, preserve the environment, and bet on a circular economy. It is vital since water is a limited resource that must be preserved. Advanced treatments allow to reuse and recycle the treated water and qualify it for its following use.” Some examples of advanced treatments for reuse water would be the disinfection of pathogens (e.g.: UV), advanced filtration (through filtering media such as activated carbon and/or anthracite, among others), advanced oxidation (e.g.: ozone) and sieving, among others.

Following the discussion, Singhal adds that the fourth industrial revolution has ushered in the era of smart factories through the digitisation of processes and systems, including wastewater treatment systems. “There is a need for predictive analysis and decision support systems in order to operate and maintain the water and wastewater management infrastructure in smart factories.”Areas for optimum utilisation of recycled wastewater

Reclaimed or recycled water can be used for a lot of non-potable purposes in municipal, commercial buildings, and industries. A lot of it goes toward watering golf courses and landscaping alongside public roads, etc. “Some industries such as power generation plants can use reclaimed wastewater. A lot of water is needed to cool power generation equipment, concrete mixing, artificial lakes, etc., and using wastewater for this purpose means that the facility won’t have to use higher quality of water that is best used somewhere else,” says Sirsi.

However, most of the water is utilised in buildings for washing cars, flushing toilets, maintaining landscapes and wherever applicable. Systems run a dual piping system to keep the recycled water separate from the potable water. Deploying the right solution/technology can ensure that wastewater can be recycled and used for drinking purposes as well. This would be particularly beneficial in water-scarce areas to improve accessibility.

It is estimated that the world population is going to double in the next 35 years. As per a World Bank report, India is among the world’s most water-stressed countries. “With further increase in population, we will witness rise in water consumption levels, water scarcity, and the need for sustainable infrastructure. Since a large portion of water runs back into the ecosystem as wastewater, it can pose great environmental and health hazards if not treated. Among the multiple means for addressing water problems, one top-of-the-line option is the IoT-enabled EcoStruxure for Water and Wastewater from Schneider Electric. Based on an open, interoperable platform, it offers enhanced value revolving around safety, efficiency, reliability, connectivity, and sustainability,” says Singhal.

Manufacturing plants today are taking several measures to remove impurities and recycle wastewater that is generated during manufacturing processes such as dissolved air flotation, biological treatment using natural bacteria to break down carbon-based impurities, filtration through filters, carbon filters and micro filters, softening, disinfection, and deionisation.

The industrial sector in India consumes 6 percent of the country’s freshwater and is the second highest water consumer after agriculture. Considering that the country is facing an unprecedented water crisis, it is important that we work together to use and reuse water in our facilities wisely while also reducing our overall dependency on fresh water. It is also essential that we move closer to effective water and wastewater management by streamlining our processes and adopting innovative practices of water reuse to ensure a “water-secure tomorrow”.

Sanjeev Sirsi, Associate Vice President – Water Utility, Grundfos Pumps India Pvt. Ltd.

Reusing treated water is the best way to boost the efficiency of purification process, preserve the environment, and bet on a circular economy.

Meenu Singhal, Vice President – Industry Business, Schneider Electric India

Sustainable and cost-effective, a decentralised wastewater treatment system is apt for India as it works well in rural, suburban and urban settings.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.