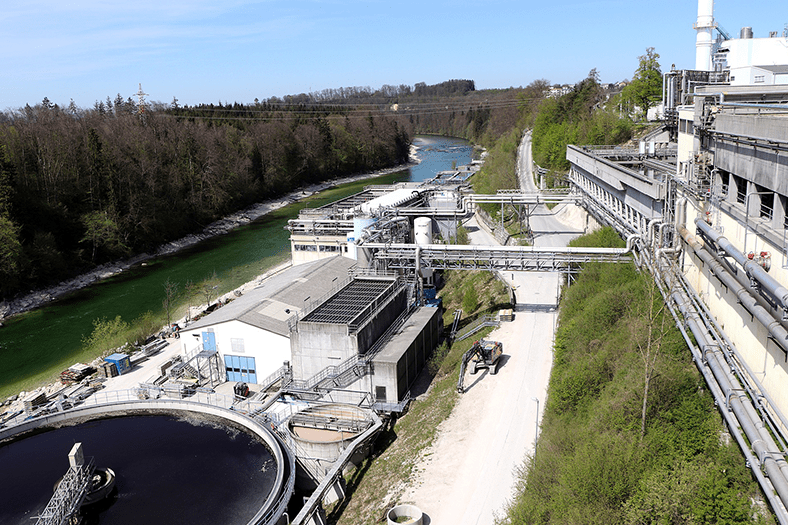

Enhancing wastewater treatment process for a foreseeable future

By OEM Update Editorial June 22, 2021 9:39 pm IST

Though the dangers of waste products, such as disease, only became evident over time, ancient societies long tried to manage the problem.

For example, the Ancient Greeks built covered sewage systems, some of which still operate today, 4,000 years later. Romans, the Indus Valley people, and China’s Northern Song Dynasty all made breakthroughs in the ancient waste management world. But it was only around the rise of industrialisation, such as London’s Bazalgette sewer system from the mid-1800s, that modern wastewater management became a concept. We have learned a lot since then, explains Chetan Mistry, Strategy and Marketing Manager for Africa, “There’s no doubt that modern sanitation practices have created a better world. There is less disease, cities are no longer dangerously septic, and clean water is something available to most people on the planet. But there are still many improvements that we can make. For example, the idea of pollution dilution is completely outdated.”

Not everything disappears in dilution

Pollution dilution was, at face value, a sound idea for its time. It holds that waste such as affluent will become harmless once introduced into much larger bodies of water. But it’s insufficient, bad for the environment, and potentially very harmful to humans.

“We’ve become much more aware of what is in waste. As detection methods improved, the world learned that waste contains previously undetected things such as medicinal waste, microplastics, endocrine plastics, and hormone disruptors. These types of waste are not diluting in the ecosystem, nor do they need large quantities to be a risk factor for humans.” There is growing acknowledgement that it’s not wise to pump waste, treated or otherwise, into our water systems – especially when you look at how much more urbanised and densely populated our cities are becoming.

These newly discovered types of waste need tertiary steps to remove, often mandated by national and international laws governing the quality of water. Underpinning those efforts, and driving more efficiencies for water treatment, are monitoring, measurement and tracking technologies.

Improvement Wastewater Treatment

The standard wastewater cycle, in broad strokes, requires the removal of grit, sand, organics, large objects, and creatures such as bacteria. New types of waste add to those processes. This is an opportunity to systematically improve all of the treatment cycle, through the following elements:

- Better tracking and measurement – It is much more feasible and cost-effective to introduce sensors into a treatment facility, monitoring factors such as affluent flow and maintenance requirements. The cost of sensor systems is so low that the payback of such investments can be as little as 2 to 3 years. Operators and managers have access to dashboards and alerts to look at every aspect from one view.

- More visibility and control – Dashboards combined with sensors create increased visibility of a facility. Current modernisation takes it a step further. You could typically expect to get facility information at the facility. But what about remotely on your phone, including the ability to change schedules or start/stop pumps even if you’re not onsite? These capabilities sit at the heart of modern facility management technologies.

- Optimisation through analytics and data – The better collection of data, combined with greater visibility and control, come together to offer a new level of facility optimisation. By leveraging artificial intelligence, data and analytics, it’s possible to have a single control, always visible, and continually learning system to run a facility. At Xylem, this confluence of technologies and management practices is called BLU-X: a holistic approach to wastewater management to avoid practices such as bypassing by predicting upstream events through past and current data.

- Improved maintenance – One of the most frequent problems at wastewater facilities are the breakdowns or clogging up pumps and pipes. Several strategies address these issues, including the tracking and monitoring features mentioned above. Modern pumps, such as the Flygt range of ‘grinder’ or ‘chopper’ pumps, help prevent clogs and also reduce maintenance of the equipment. These modern pumps provide sensor data for maintenance and control. They also make the enforcement of maintenance contracts simpler and more effective.

- New sanitation technologies – In terms of sanitation chemicals, chlorine is still the most popular due to its low cost and ease of use. Yet, there are drawbacks of a chlorine-heavy treatment cycle, including the risk of carcinogens and environmentally damaging contamination in the water supply. Systems using ozone and UV sanitation have matured considerably, offering complimentary enhancements to traditional sanitisation processes. These can fit into major treatment facilities, and are also immensely useful for smaller facilities, site cleaning and ad-hoc applications.

- Raising $1 billion in a green bond offering – the first of its kind for a US industrial company;

- Reducing company water use intensity by 30 percent over the last six years – nearly 10 percent versus 2019, alone;

- Reducing company net greenhouse gas emissions intensity by over 7 percent versus 2019;

- Committing to a sustainable fleet strategy to transition the global vehicle fleet to electric and hybrid;

- Launching a U.S. supplier diversity program;

- Increasing transparency in its supply chain by engaging suppliers to report into EcoVadis and CDP and take the WASH pledge;

- Further aligning business and sustainability performance by tying five key 2025 sustainability goals to long-term incentives for an expanded group of executives.

The above enhancements don’t need to replace current facilities. But there is room for improvement, and the combination of digital technologies and modern best practices open a world of choice for current and future wastewater treatment facilities. These can be introduced at various levels, says Mistry.

“The best place to start is creating visibility. Put in a few sensors and start collecting the data, then put it through analytics and dashboards to help your decision making. You can focus on a specific part of the facility, using successes there to motivate for other improvements. Ultimately, you’ll realise efficiencies and operational improvements that didn’t even exist not that long ago. This is probably the most exciting time for a treatment facility, because the possibilities are enormous and very flexible, including modular and single-tank processes.”

In 2020, Xylem made significant progress toward its sector leading 2025 signature sustainability goals, despite the additional challenges of COVID-19. Through its advanced products and technologies, the company helped customers reduce their carbon footprint by 0.7 million metric tons of CO2, equivalent to keeping 150,000 passenger cars off the road for a year. Xylem is now running almost half its major facilities on 100 percent renewable electricity, and has committed to transition its global vehicle fleet to electric and hybrid, targeting an initial 45 percent reduction in fleet CO2 emissions by 2023.

In addition to advancing its existing sustainability goals in 2020, Xylem made new commitments to address the pandemic’s impact, around the world. The Company doubled philanthropic investments and extended new support to employees, business partners and the communities they serve. It also expanded relationships with its global NGO partners, like Americares and UNICEF, supporting 4.1 million people in underserved communities to get access to water and sanitation and providing 3.6 million people with water education to raise awareness and improve their quality of life.

“As a company, we recognise the opportunity we have to lead, given the breadth of our technologies and our global reach,” said Claudia Toussaint, Xylem’s Chief Sustainability Officer. “We navigate difficult times in ways that make us stronger and more resilient — and support our customers and communities to do the same. With that mindset, we pulled together across our organisation, and with our partners around the globe, to help mitigate the impacts of COVID-19 while continuing to deliver on our sustainability commitments.”

Among the actions and achievements from 2020 detailed in the GRI-compliant report, additional highlights include:

To learn more about Xylem’s sustainability progress, download Solving Water for a Resilient World., by visiting www.xylem.com.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.