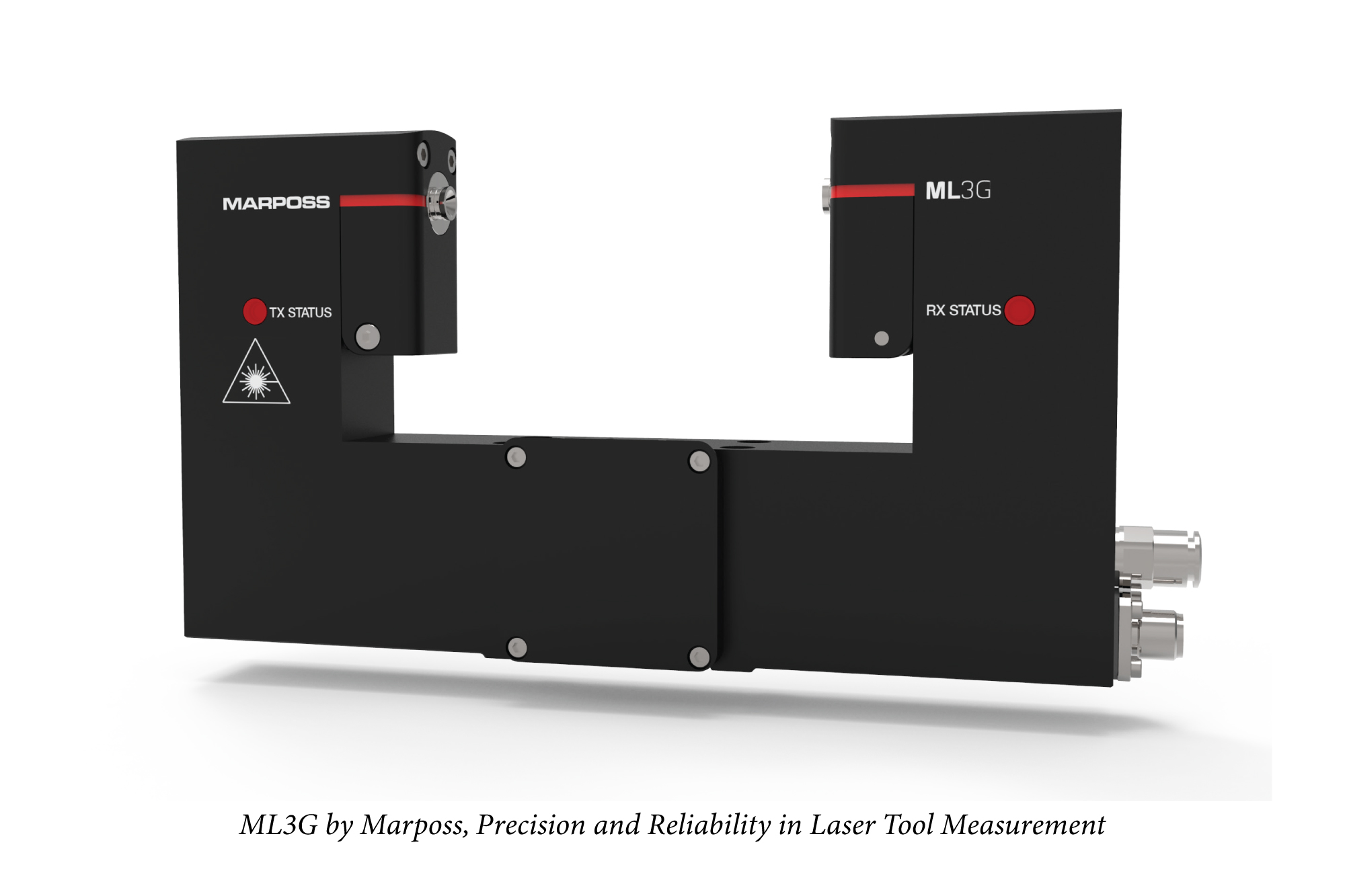

Marposs presents ML3G: A new standard of reliability and performance in tool setting

By Staff Report September 10, 2025 6:08 pm IST

MARPOSS, a measurement, inspection and testing solution provider for the production environment, introduces ML3G, a next-generation non-contact laser tool measurement system offering precision, speed, and reliability. It comes with advanced features for dynamic inspections, tool integrity, and enhanced productivity in demanding machining environments.

ML3G is a non-contact tool measurement system designed to control any tool type directly on the machine. The main feature of a “non-contact” tool setter is that the measurement is performed by interrupting a laser beam instead of mechanical contact with a stylus. This offers several advantages:

• Measurement of small and fragile as well as coated tools without risk of damage.

• Measurement at the real cutting speeds, even thousands of RPM, eliminating errors caused by run-out or length variations possible under dynamic conditions.

• High flexibility, allowing measurement of a wide range of tools and, at the same time, the possibility to perform many types of inspections.

ML3G is mainly used to make precise tool pre-setting (measurement of tool diameter and length), with automatic writing of values into the machine variables, with a consequent reduction of the risk of manual errors.

Additionally, the system is also usable for tool breakage detection, integrity verification, and cutting-edge profiles scanning. All this translates into reduced scrap and increased production.

Innovations Introduced by ML3G

The new ML3G introduces a series of innovations that enhance its performance compared to previous models. The upgrade features a more powerful processor for faster measurement speeds and advanced controls, including a monitoring tool that measures vibration amplitude and frequency. This is particularly valuable in Ultrasonic Machining applications. The system also features newly designed shutters that provide perfect sealing and a new fixing system that simplifies maintenance. An integrated air blower ensures efficient tool cleaning, while the reinforced mechanical structure guarantees stable alignment between emitter and receiver, even in the most demanding operating conditions.

Why Choose ML3G

ML3G is designed to meet the most stringent requirements in tool setting. It delivers fast and accurate measurements that help maximise productivity, even during dynamic inspections with the tool rotating at real cutting speeds. Built to withstand harsh environments, the system ensures maximum protection against coolant and chips. Its versatility is another strong point, with multiple configurations available: four lengths and three mounting options to suit a wide range of machine setups.

Further details are available at EMO 2025 (Hall 5, Stand D13) and on the Marposs website: https://www.marposs.com.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.