Dürr introduces space-saving oven technology for Byton

By OEM Update Editorial October 9, 2018 5:21 pm IST

Dürr, an automobile paint specialist, has developed a new concept in vehicle drying with EcoInCurefor Byton FMC to construct a new paint shop in Nanjing, China. The primary features of the paint shop will be the reduction in carbon footprint by 20 per cent and the use of pioneering technologies.

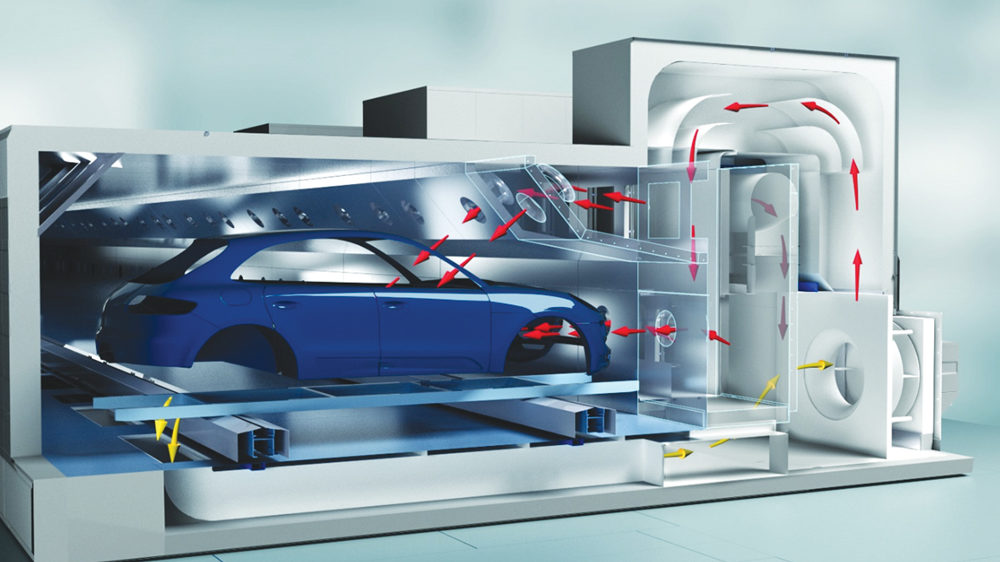

In the new concept, automotive bodies are heated from inside out with the help of jet nozzles, enabling uniformity of heating. This process improves topcoat quality and process performance.

Dürr’s scope of delivery for the new paint shop includes the RoDip (rotational dip) process for pretreatment and electrocoating, and all the robotic and application technology for the sealing and painting processes.

The electrocoating stage uses EcoDC MACS — an energy-saving and fail-safe system. This technology uses modular anode control to create a voltage profile in the tank that moves with the body. The robots in the spray booths are equipped with the EcoBell 3 atomiser generation. The semi-automatic EcoDryX dry separation system, which separates the overspray in the paint booths for primer and topcoat, requires no water or chemicals. In addition, Dürr has been designing a downstream exhaust air purification system made up of Ecopure KPR VOC adsorptive concentration system with combined thermal exhaust air purification using the Ecopure RTO.The scope of delivery includes material feeding for PVC and paint, shop ventilation, fire protection for the process systems, and a reverse-osmosis plant. The exhaust air from the ovens is purified via the Ecopure TAR recuperative thermal process, which also provides all the heat for heating the oven in an energy-efficient way.

Despite the extensive equipment, the design of the plant would be very compact, thanks to EcoInCure. This is because the oven transports bodies transversely, halving its length compared to conventional systems. All in all, this Eco+Layout from Dürr reduces the paint shop’s footprint by 20 per cent.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.