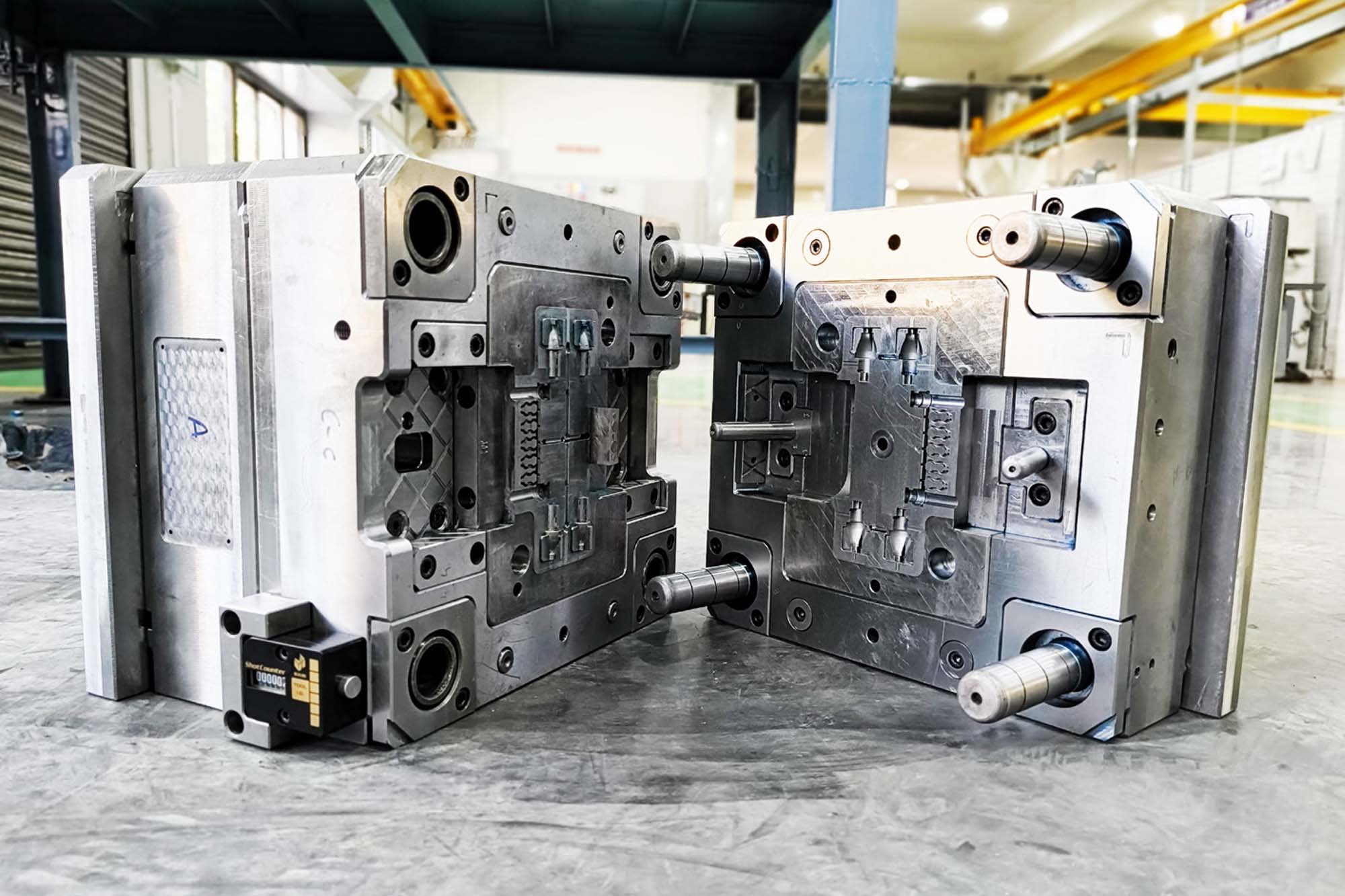

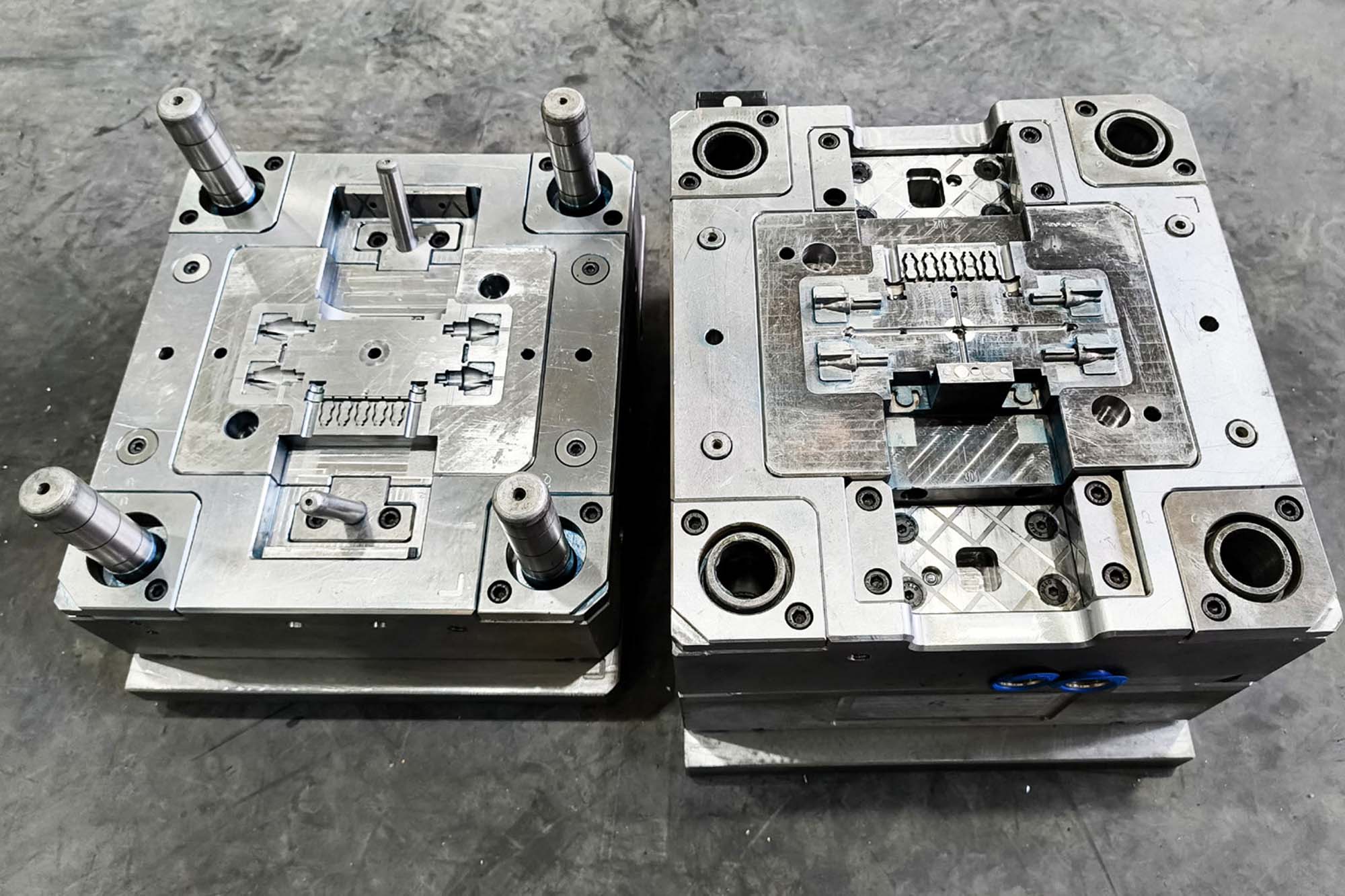

Thriam Toolroom achieves T0 in 26 days for injection mold manufacturing

By Staff Report May 9, 2025 5:22 pm IST

The company completed a complex family mold project with tight tolerances and advanced design requirements, showcasing its commitment to speed and precision.

Thriam Toolroom, a rising force in the mold manufacturing sector, completed a complex family injection mold project in 26 days. This feat, achieved amidst the intricate demands of tight tolerances and a sophisticated design, marks a significant milestone for the company and sets a new benchmark for the industry. The project, characterised by its intricate design and stringent specifications, presented a formidable challenge. The company’s advanced manufacturing capabilities, powered by a robust machine line-up featuring Haas, Fanuc, and Mitutoyo technologies, were pivotal in achieving this remarkable turnaround time.

Minu Madhukumar, CEO of Thriam Toolroom, expressed immense pride in the team’s accomplishment, stating, “We are now at our highest conviction towards achieving plastic mold manufacturing in 21 days after this achievement, because what seemed impossible to everyone now looks clearer to us.

This achievement highlights Thriam Toolroom’s technical capabilities and reinforces its strategic vision to position itself as a leader in timelineoriented mold manufacturing. The company’s focus on speed and efficiency is driven by a deep understanding of the critical importance of time-to-market for its clients. Thriam Toolroom empowers its customers to reduce their product development cycles and gain a significant competitive advantage by accelerating the mold manufacturing process.

Thriam Toolroom’s commitment to delivering exceptional results is rooted in its state-ofthe-art facilities and a team of highly skilled professionals. The company’s investment in technology and its dedication to continuous improvement enable it to handle even the most complex projects with unparalleled efficiency and precision.

The company’s ability to achieve such rapid turnaround times is a testament to its streamlined processes and optimized workflows. By leveraging advanced CAD/CAM software, employing lean manufacturing principles, and maintaining rigorous quality control measures, Thriam Toolroom ensures that every stage of the manufacturing process is executed with utmost precision and efficiency.

Thriam Toolroom emphasises collaboration and communication to ensure that its clients are kept informed throughout the process. This transparent and customer-centric approach fosters strong relationships and builds trust, reinforcing the company’s reputation as a reliable and dependable partner.

In a market where time is of the essence, Thriam Toolroom’s ability to deliver molds in record time provides its clients with a significant competitive edge. By reducing time-to-market, the company enables its customers to launch new products faster, capitalize on market opportunities, and drive growth.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.