Atos ensures hydraulic safety in compliance with the Machinery Directive 2006/42/EC

By Staff Report August 21, 2025 6:34 pm IST

Atos places safety at its core, which is evident in its strict compliance with the Machinery Directive 2006/42/EC while manufacturing valves. This sets a new benchmark in hydraulic protection through innovation and accident prevention.

The Machinery Directive 2006/42/EC is a crucial piece of legislation that outlines the safety requirements for machinery and equipment in the European Union. The directive sets out specific safety measures and guidelines that manufacturers must follow when designing, manufacturing, and commissioning hydraulic equipment. These measures include the use of safety valves to promote a safer working environment and maintain the operational efficiency of machinery.

Understanding Machinery Directive 2006/42/EC

The Machinery Directive 2006/42/EC, with relevant harmonised standards IEC 61508 Safety Integrity Level (SIL) and ISO 13849 Performance Level (PL), contains the general principles concerning machine safety, which manufacturers have to consider to reduce the risk related to machine operation.

Established by the European Union, the Machinery Directive 2006/42/EC is important for equipment safety within its member states. This directive sets up essential rules for operators’ health and the safety requirements for machinery throughout its entire lifecycle, from initial installation and ongoing maintenance to eventual disposal. Addressing a wide range of safety aspects allows the directive to ensure that machinery is designed and manufactured with the utmost priority on the well-being of operators.

Two crucial harmonised standards ensure the safety of hydraulic systems: ISO 13849 and IEC 62061. These standards provide a framework for manufacturers to assess and mitigate risks by considering the reliability of components, the architecture of the control system, and the severity of potential hazards.

Performance Level (PL) and Safety Integrity Level (SIL) are two important concepts when evaluating the effectiveness of safety measures in hydraulic systems. These levels measure the ability of safety functions to perform their intended task under specific conditions. By assessing these factors, manufacturers can determine the appropriate PL/SIL required for their hydraulic system and see if the implemented safety measures are adequate for the intended application.

By understanding the Machinery Directive 2006/42/EC, industrial engineers will have the knowledge and insights needed to revolutionise the functional safety of hydraulic systems. This results in increased reliability, improved performance and ultimately creates a safer industrial environment for operators.

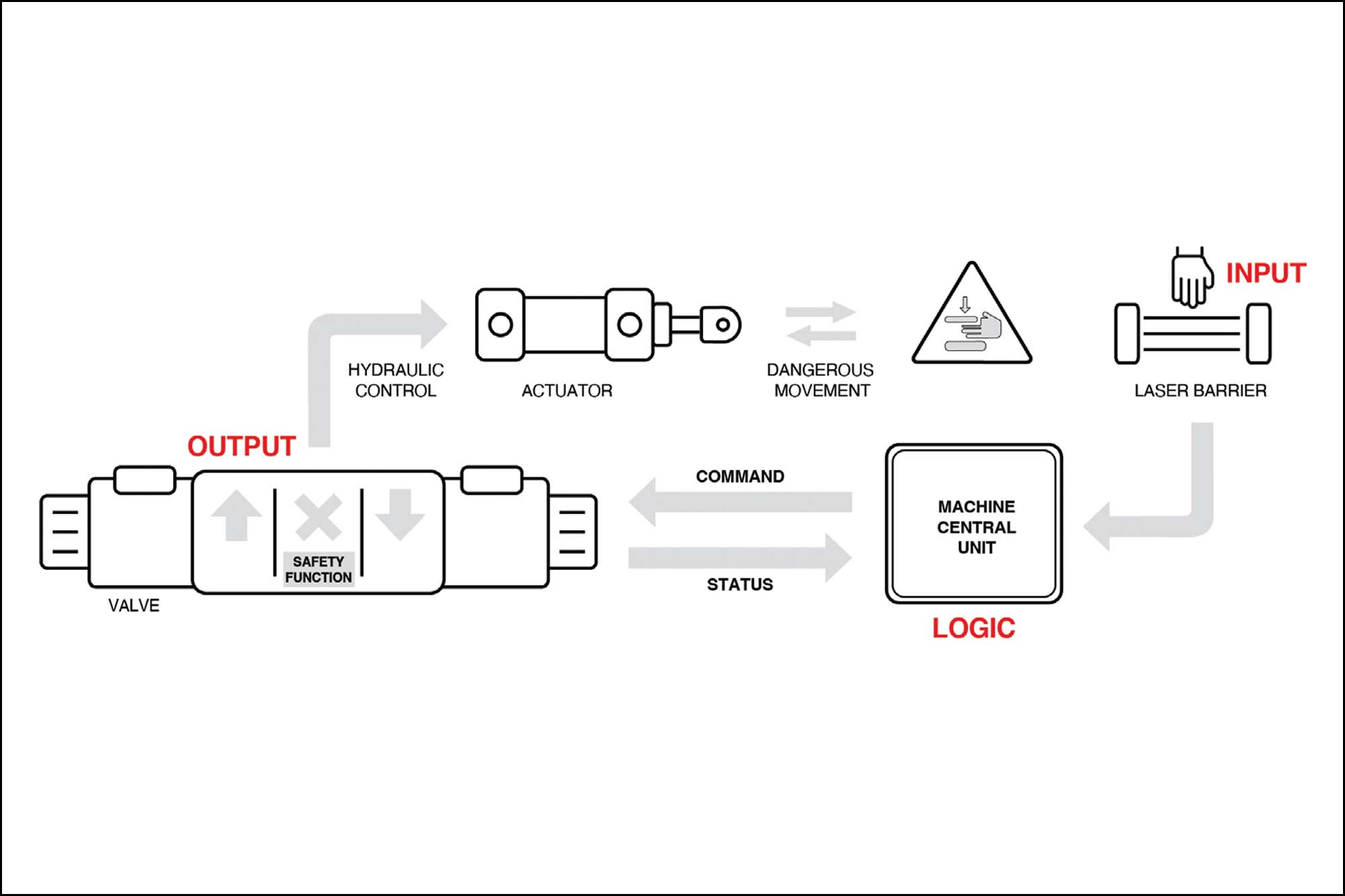

The role of safety valves in hydraulic systems

As functional safety becomes increasingly important across industry sectors, understanding the role of safety valves and their contribution to achieving compliance with ISO 13849 and IEC 62061 standards assumes ever-greater importance.

Safety valves are designed and tested to meet stringent safety standards and regulations. They exist to ensure the overall safety and reliability of hydraulic systems. They are engineered with advanced features like monitoring systems and fail-safe mechanisms, meeting the highest safety level. In practice, safety valves help in limiting potential risks to equipment or operators, preventing dangerous movements of electrohydraulic axes during production cycles or emergency conditions.

However, it must be taken into consideration that the overall SIL and PL assessment does not depend solely on the characteristics of a single component. SIL and PL assessments consider the entire chain of safety-related components working together to perform the safety function.

Hydraulic system architecture plays a fundamental role.

Safety valves can be integrated into redundant double-channel systems to achieve higher safety levels and enhance system complexity.

Numbers and types of faults detected can be improved by introducing safety mechanisms into the system architecture to increase the overall diagnostic coverage.

Atos safety valves

Atos has developed a range of safety valves specifically designed for functional safety. They undergo rigorous testing processes for their quality, reliability, and compliance with industrial safety standards. Atos safety valves are supplied with certification approved by a notified body, facilitating the machine design phase and the system certification process.

Atos offers a complete range of on-off valves and cartridges with inductive safety sensors to monitor the spool or poppet position, used by the machine central unit to confirm the safe status of the valve.

When it comes to proportional controls, Atos has developed a range of digital proportional valves with onboard electronics designed and certified for functional safety.

Atos proportional safety valves meet safety standards by inhibiting the regulation of the proportional valve via on-off enable signals. The valve confirms when the safe spool position has been reached by sending on-off digital signals to the machine’s central unit.

Atos follows the Machinery Directive 2006/42/EC to ensure its safety valves meet strict safety standards. These standards help prevent accidents and protect both machinery and people. Atos is committed to improving and innovating its products, providing the best protection for hydraulic systems.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.