Pilz powering hydrogen without hazards

By Staff Report June 19, 2025 6:37 pm IST

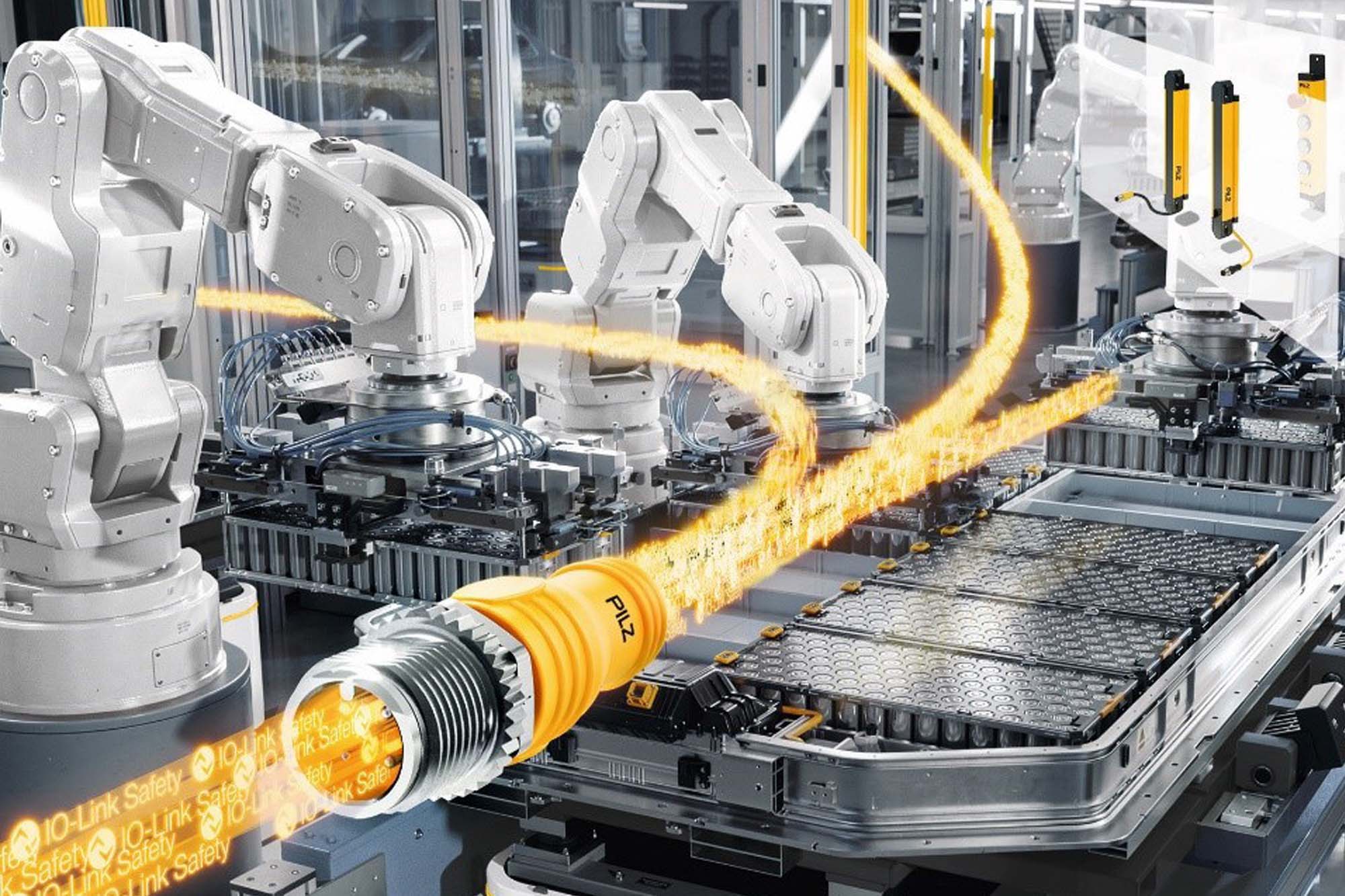

Pilz believes that an early, holistic approach to safety and security in the hydrogen industry guarantees protection. With automation solutions, hydrogen can be utilised safely and economically throughout the value chain, from its production in electrolysers to storage, transport, and use in fuel cells or industrial burners.

Hydrogen: Safe energy carrier or explosive challenge?

Hydrogen is considered the energy carrier of the future. Its potential uses are diverse and continue to grow. In industries, hydrogen plays a crucial role in processes such as steelmaking, as well as in the chemical and glass sectors. It is also gaining momentum in mobility as a clean fuel for fuel cell vehicles and can be used to generate electricity through fuel cells. The downside of the energy carrier is that it is a colourless and odourless gas that is also flammable. Appropriate safety measures and safe monitoring systems are required during production and handling.

Appropriate safety measures and reliable monitoring systems are therefore essential during the production and handling of hydrogen. What is becoming increasingly clear is that public acceptance of new technologies is closely tied to how well-associated risks are managed, and potential errors are addressed. Even in these emerging application areas, it is extremely valuable to use the experience gained from over 40 years of functional safety in the industry. With its automation solutions, Pilz ensures that hydrogen can be used safely and efficiently across the entire value chain of this energy carrier: from H₂ production in electrolysers to storage and transport, all the way to its use in fuel cells or industrial burners.

Safe, efficient storage and transportation

For transportation, hydrogen is highly compressed and carried in special high-pressure tanks by rail, water, or road. However, rapid pressure changes, such as those that occur during the filling or emptying of hydrogen or even due to temperature fluctuations, can place repeated stress on the composite transport containers. This can lead to delamination (where the material’s layers separate), reduced service life of the pressure vessel, leakages, and, in the worst case, explosions.

To protect both the hydrogen tanks and people near transfer points, special safety precautions are essential during the filling and emptying processes. Pilz’s proven, safe controllers reliably monitor these transfer operations using failsafe analogue value processing and can automatically halt the process if an error occurs.

In Bremerhaven, Germany, energy company GP JOULE relies on Pilz’s safety solutions. GP JOULE converts surplus wind energy into CO₂-neutral hydrogen, stores it in tanks mounted on specialised truck trailers, and delivers the highly flammable gas to hydrogen refuelling stations in the city. Among others, buses operated by Bremerhaven Bus are refuelled with this green energy. Thanks to Pilz, the loading and unloading of these pressure vessels is not only simple and quick—but most importantly, safe—at all transfer points.

Safety-related accuracy: measured values accurate to within 1 %

The process values that are critical for hydrogen (H₂) refuelling or storage are recorded using safe analogue sensors and read by a safety controller. When monitoring pressure levels between 0 and 1,000 bar, it’s essential to maintain safety accuracy throughout the entire monitoring system. Risk assessments for tube trailer refuelling have shown that even a 1% accuracy (which equals 10 bars in this case) can meet safety standards.

In practice, the specification of the analogue signal is often considered sufficient. This may seem acceptable based on the datasheet, but it doesn’t automatically make it suitable for use in safety-related designs. It’s important to take a closer look.

After the process values are captured, it is essential to ensure that the absolute (static) limit values are not exceeded and to detect any dynamic changes as needed. This calls for more advanced monitoring functions, such as safe gradient monitoring. The “Safe Ramp Monitoring” software block checks whether pressure and temperature changes are happening within the safe rise and fall limits, as well as the speed at which hydrogen is being filled or emptied. If these values exceed the safe range, the safety controller responds – for example, by slowing down a regulator or compressor or by completely closing a valve.

A holistic approach to safety and security

Automation solutions can support the traditional mechanical safety features of components used in the hydrogen industry. This is important because functional safety always looks at how safely a process responds throughout its entire lifecycle.

Operational Technology (OT) security helps protect the availability of plants and machines from tampering and misuse. The main focus is on safeguarding plant data and knowing who has access to the process. These functions are especially important for critical infrastructure facilities.

Pilz strongly believes that taking an early and holistic approach to both safety and security in the hydrogen industry ensures complete protection. The growing hydrogen sector can benefit from many years of experience in this area.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.