WEFIRE is revolutionising safety solutions for precision manufacturing

By OEM Update Editorial April 1, 2024 3:08 pm IST

In any manufacturing unit, safeguarding machines is paramount, as they are the spark that ignites the entire operation. Rohit Warrier, Founder & CEO of WEFIRE, discusses how precision solutions redefine industry safety standards, preventing machine downtime and costly damages.

How does WEFIRE address the challenges faced by manufacturing companies with its safety solutions?

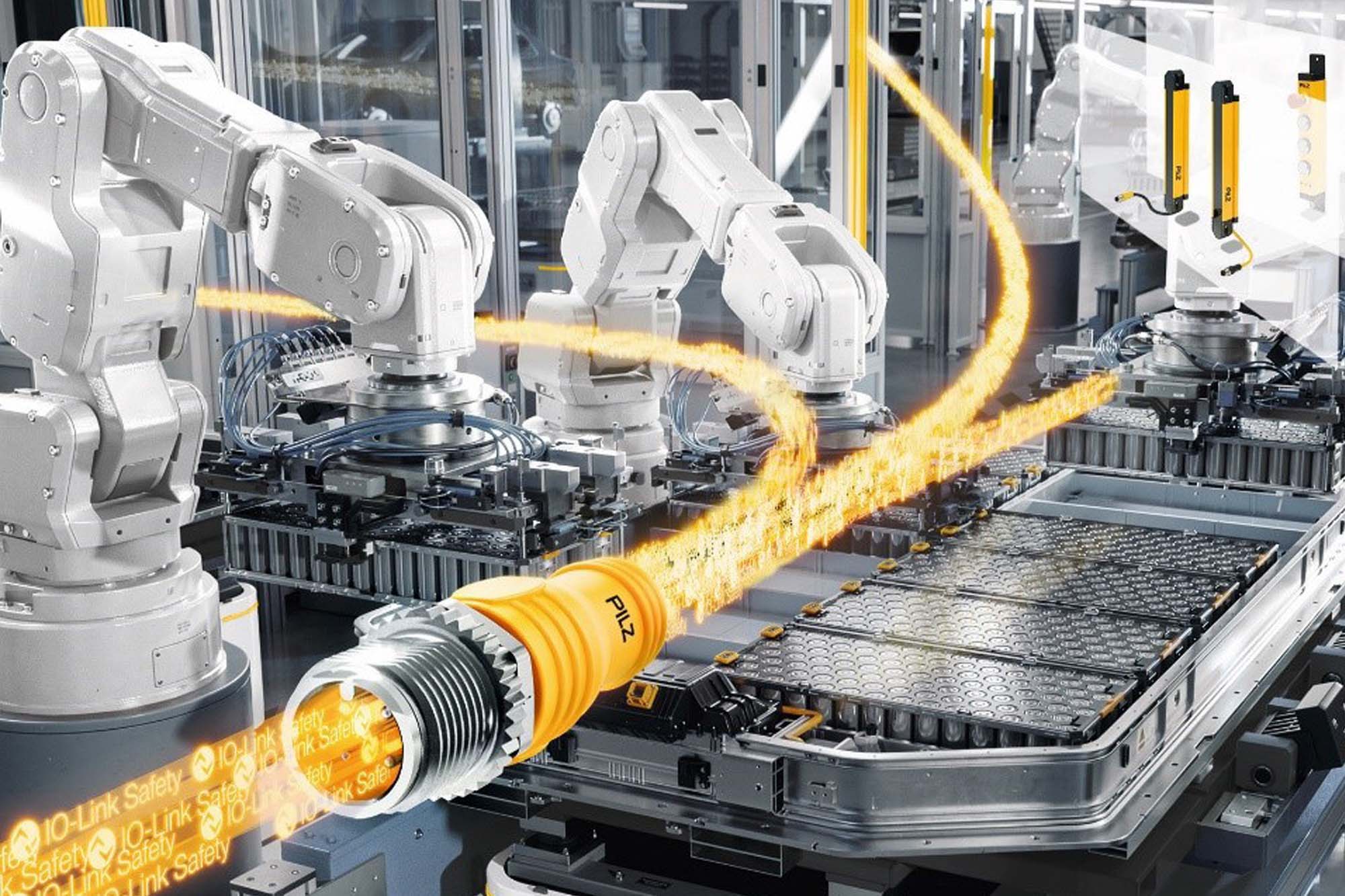

Safety is a vast subject, encompassing personnel and machine safety, particularly in manufacturing. In any business, two primary assets are people and machines. In this context, WEFIRE plays a crucial role in ensuring machine safety. In a manufacturing unit, machine downtime can bring operations to a halt. WEFIRE helps reduce, and in some instances, avoid, such precious machine downtime due to fire incidents.

Can you elaborate on how your safety products meet manufacturing units’ specific needs and requirements?

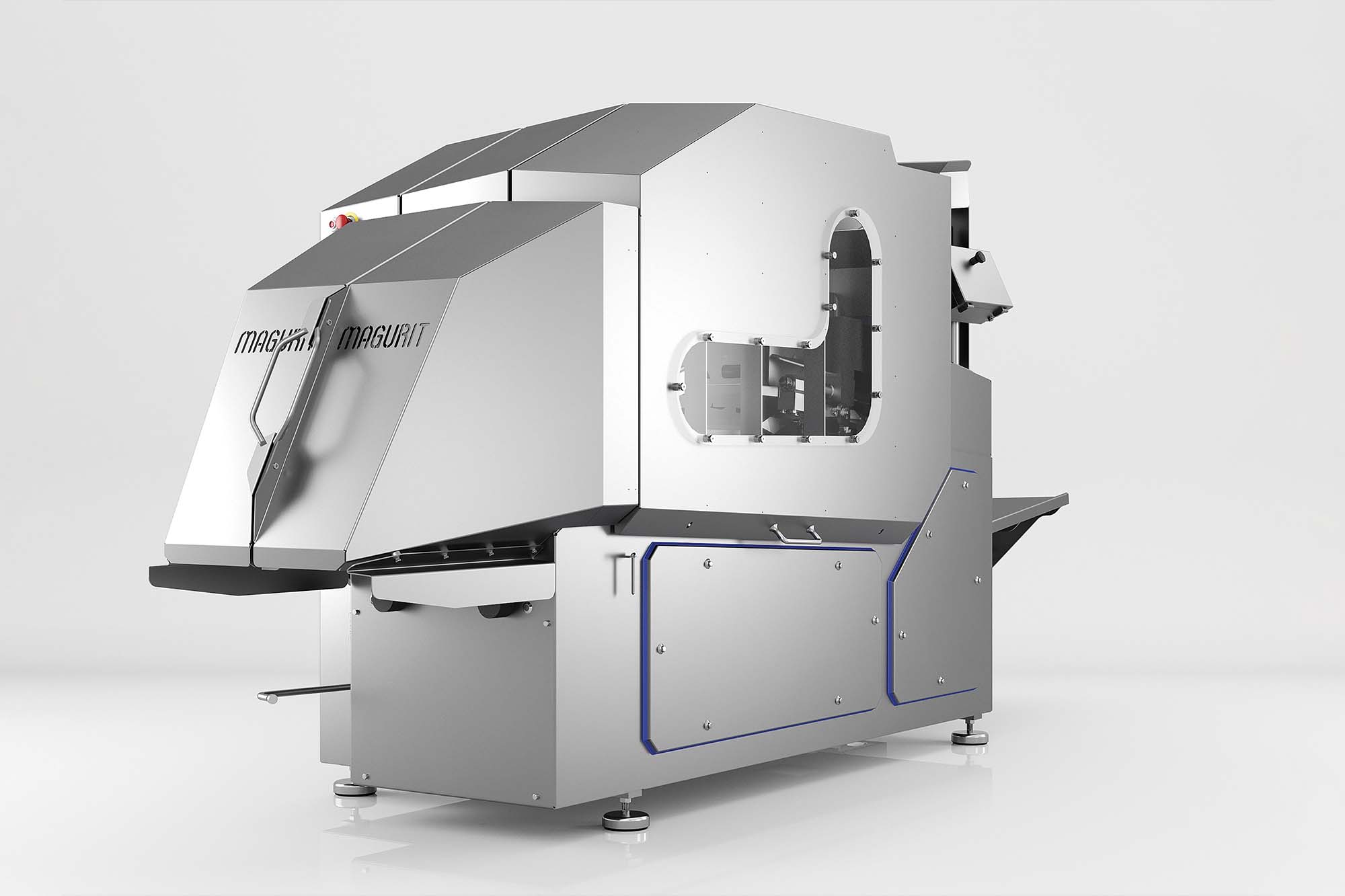

We compete with international manufacturers of fire safety products. Our core competence lies in understanding the intricacies of EDM, CNC, or honing machines and designing solutions according to specific requirements. Our deep understanding of how machines operate enables us to prevent oil leaks that could pose additional safety hazards in the plant.

What are some common misconceptions or overlooked aspects regarding safety and security in manufacturing?

The most common myth is, “There has never been a fire on my CNC in the past.” We stress the subject of CNC fires because of the higher level of threat involved in machining operations. Metal-to-metal friction generates heat, compounded by neat cutting oils (coolant) with flash points ranging from 100 degrees Celsius onwards. This is typical in machine operations and also presents a looming fire threat. We never want to fall ill, but insurance takes care of the bills if we do. Automatic fire suppression systems such as WEFIRE are akin to medical insurance.

What is the key advantage of the fire suppression system offered by WEFIRE compared to others in the market?

Our biggest advantage is the gas we use to suppress fires, 3M’s Novec 1230 or FK 5112. These gases require much less volume to suppress a fire than CO2. They also do not contaminate coolant or damage electronics inside the machinery. There is ZERO collateral damage due to the gas. Our core competence lies in understanding machine operations, allowing us to comprehend the associated costs and design solutions to lower collateral damage.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.