Intricacies of Sand Blasting vs. Shot Blasting vs. Shot Peening

By Staff Report December 7, 2024 7:04 pm IST

Users frequently confuse the surface treatment techniques of shot blasting, peening, and sandblasting. August AEETHER, International Sales Manager of AEETHER CO., LIMITED, discusses the differences between these three common surface treatment processes.

Sandblasting, shot blasting, and shot peening are common surface treatment processes. These processes treat very similar surfaces, which users often misunderstand due to their similarity and sometimes interchangeability, making it difficult to distinguish between them.

Sand Blasting

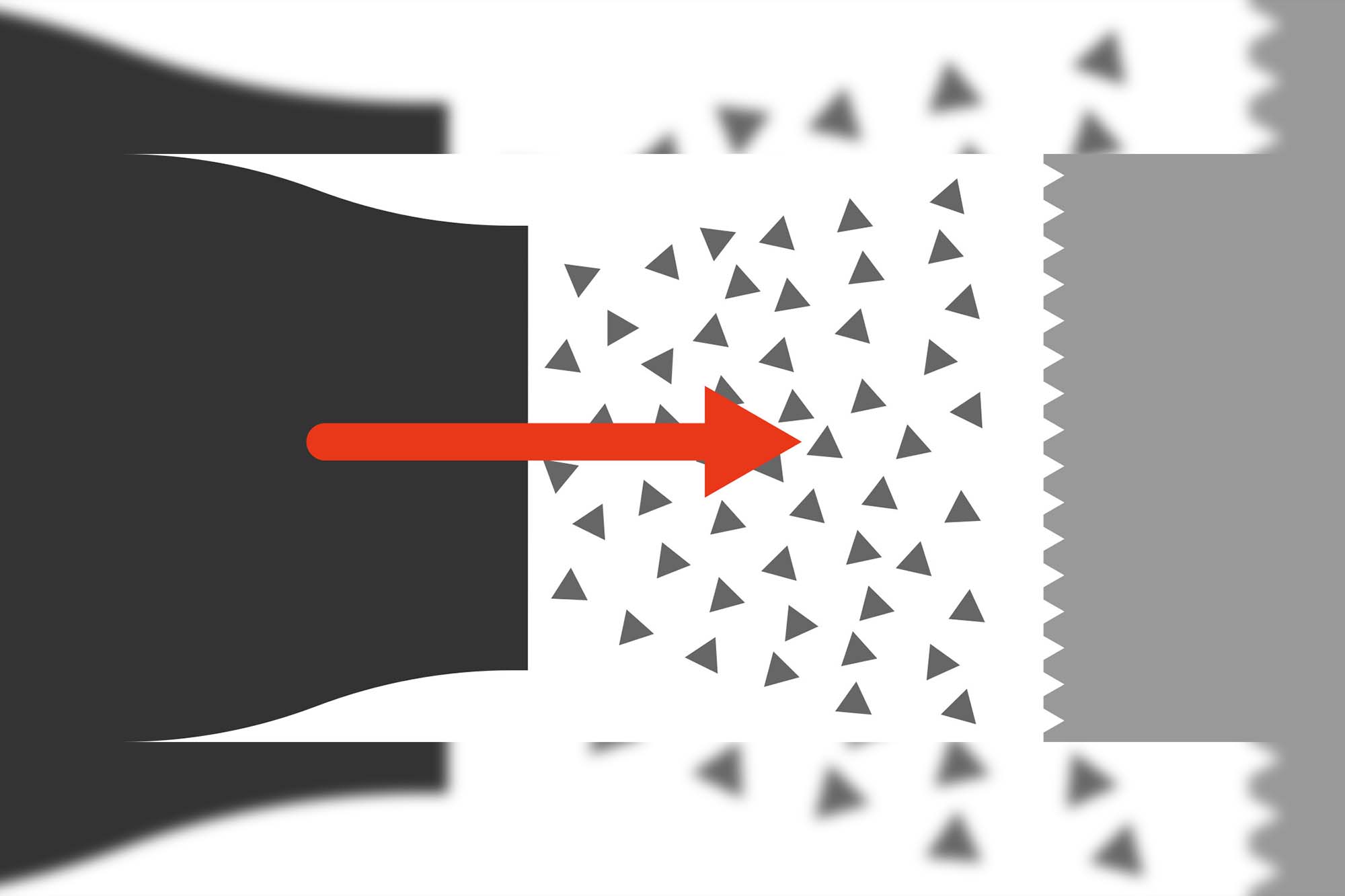

Sandblasting is spraying high-speed sand particles onto metal surfaces using compressed air to generate kinetic energy and eject particles through a nozzle. The figure is the schematic diagram of sandblasting:

The high-speed sand particles first impact the rust and foreign matter on the metal surface. Secondly, the sand particles slightly grind and cut the metal surface, thereby improving the metal surface roughness. Therefore, the metal surface will have a white frosted effect after sandblasting, as seen in the example picture.

Sandblasting is divided into manual and automatic sandblasting. Manual sandblasting requires sandblasting surfaces by hand and is suitable for more complex products, such as various pipe fittings . Automatic sandblasting is suitable for long-shaped, easy-to-rotate products like seamless pipes.

Sandblasting involves selecting various abrasives, which correspond to varying roughness. Commonly used abrasives include stainless steel, ceramic sand, and emery sand.

Shot Peening

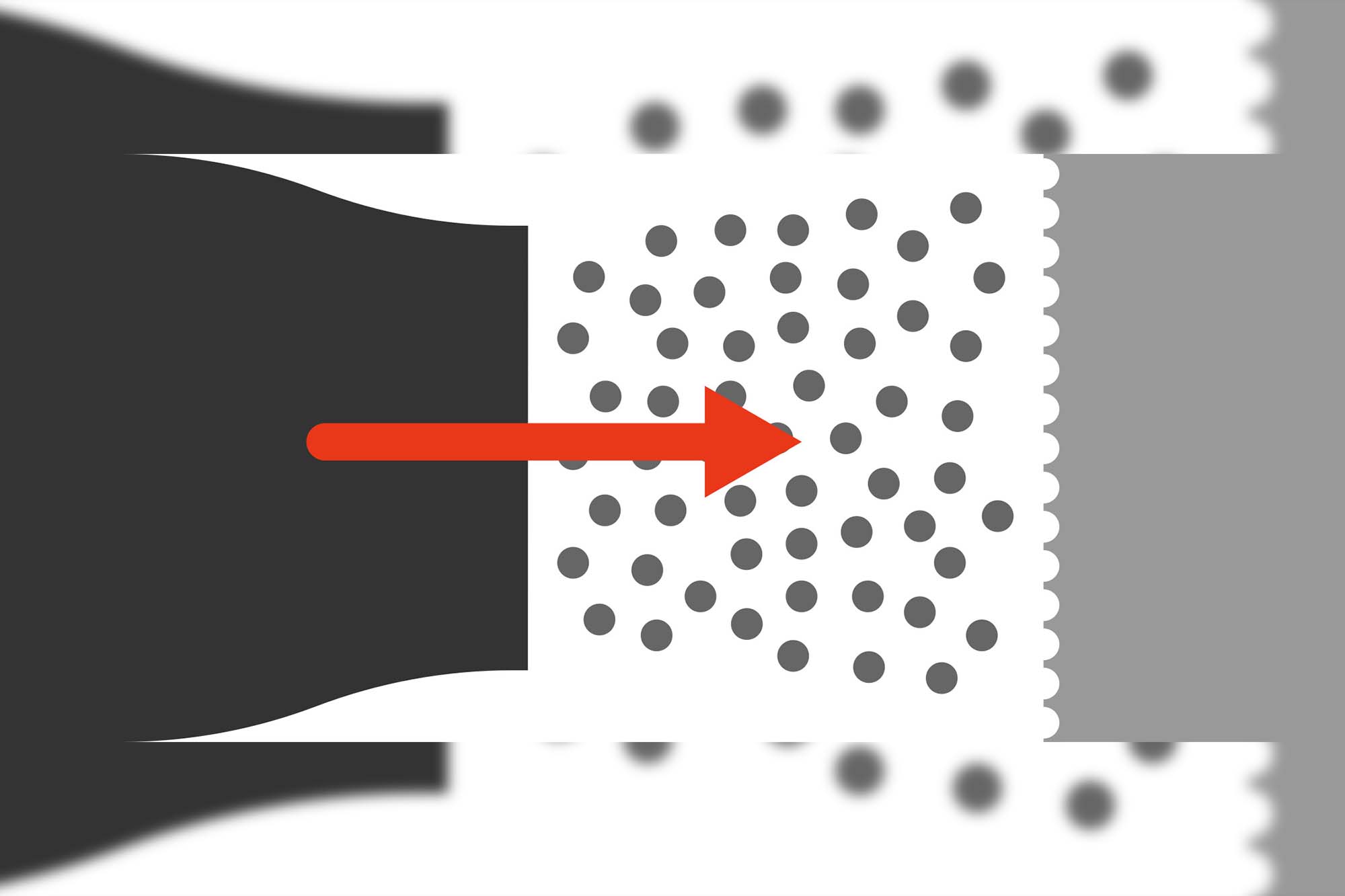

Shot peening is similar to sandblasting but shot peening sprays high-speed spherical particles. Shot peening removes defects from metal surfaces by forming small, round depressions caused by spherical particles impacting the surface. They give the metal surface a rough silver sheen and improve the cutting performance of the metal surface. The picture below shows a typical shot peened surface:

Different types of abrasives used for peening, including steel, glass, and ceramic pills, with varying hardness, should be chosen based on the specific metal materials.

Similarities and differences between shot peening and sandblastingSandblasting and shot blasting are methods to improve metal surfaces by spraying abrasive materials. Sandblasting uses angular sand particles for cutting and grinding, while shot peening uses spherical particles for impact. Sand particles are crucial for both processes.

Shot peening has higher surface roughness and visible pits compared to sandblasting. In addition, it is often manual and has a greater impact on surface mechanical properties than sandblasting, which can use more methods. These differences make shot peening a more suitable method for surface finishing.

Shot Blasting

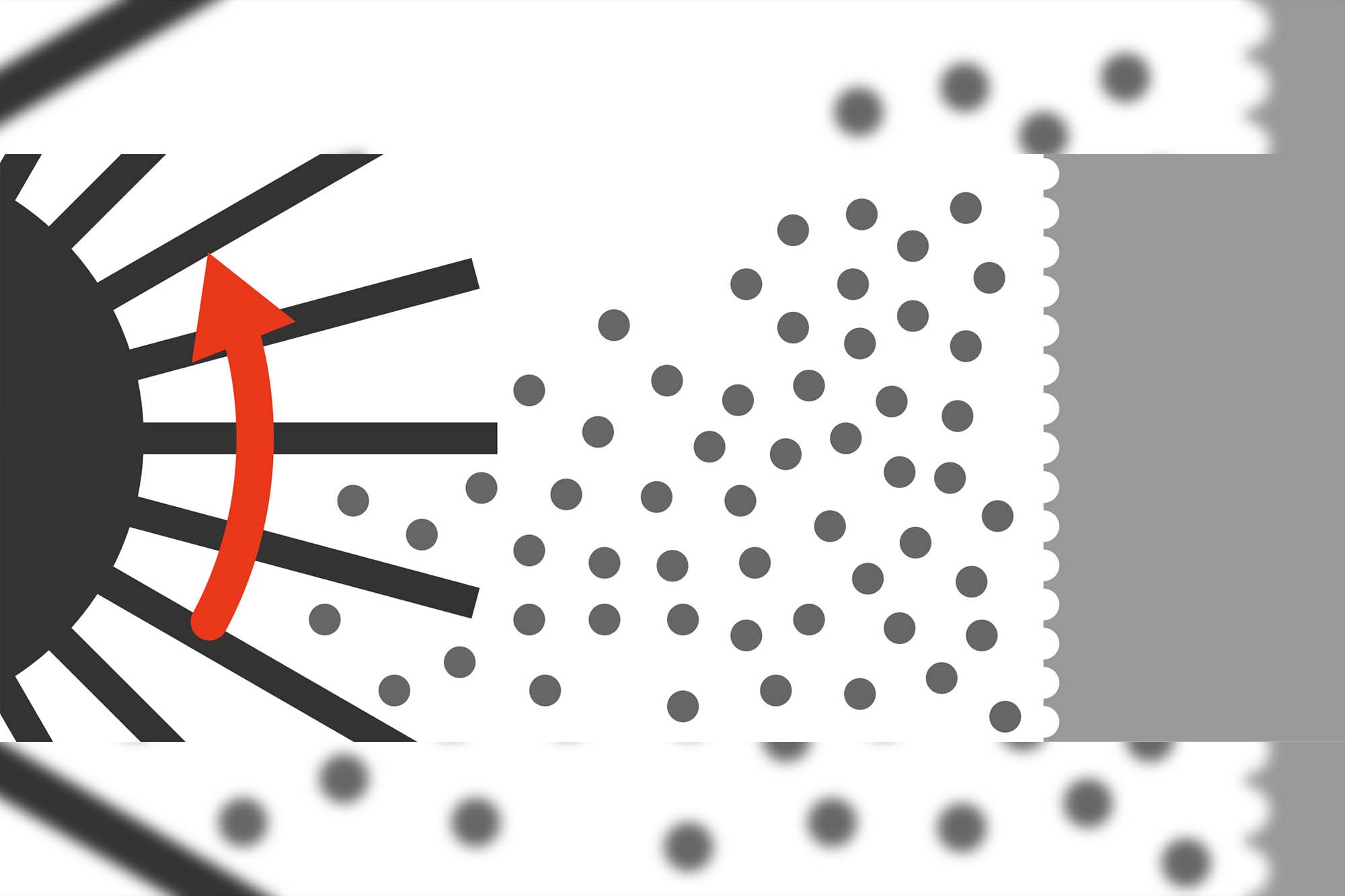

The principle of shot blasting and shot peening is the same, to make high-speed spherical particles impact the metal surface. However, shot blasting uses a rotating impeller to throw spherical particles onto the metal surface. The picture below shows the principle of shot blasting:

Shot-blasted surfaces and shot-peened surfaces are almost the same. However, shot blasting impacts the metal surface faster, so it has a greater impact on the performance of the metal surface. The picture below shows the shot blasting surface:

In terms of processing methods, the shot blasting process is completed automatically through machinery. Therefore, shot blasting is more efficient but may not always be sufficient for complex workpieces. In contrast, since shot peening is manual, it can handle every surface of complex workpieces.

The abrasives used in shot peening and shot blasting differ minimally. The main difference is the acceleration of the abrasive, similar to the relationship between manual and automatic sandblasting.

Pickled surface

Sandblasting, shot peening, and shot blasting surfaces are similar but distinct from pickling surfaces. Pickling is a chemical method to corrode the oxide scale on metal surfaces. Sandblasting, shot peening, and shot blasting are all physical methods used to treat metal surfaces. Pickling is an intermediate process in metal processing and requires metal pickling before sandblasting, shot peening, or shot blasting.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.