Why Digital Twin and Smart Manufacturing are now business imperatives

By Staff Report September 12, 2025 6:35 pm IST

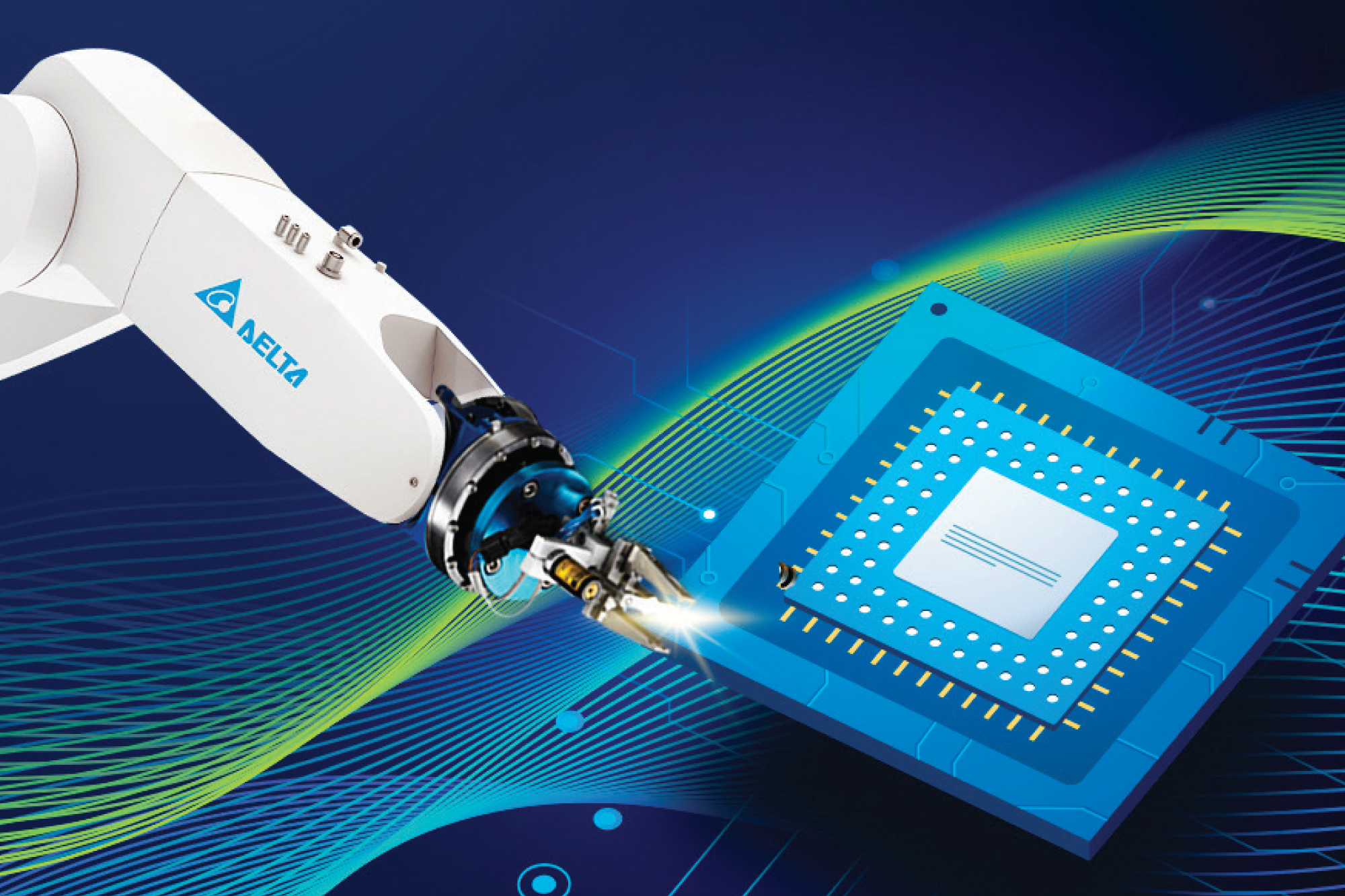

By leveraging a cohesive architecture—like Delta’s suite of solutions, including DIATWIN, DIASECS, DIAEAP+ and DIASPC—companies can unify fragmented systems into a single, intelligent ecosystem.

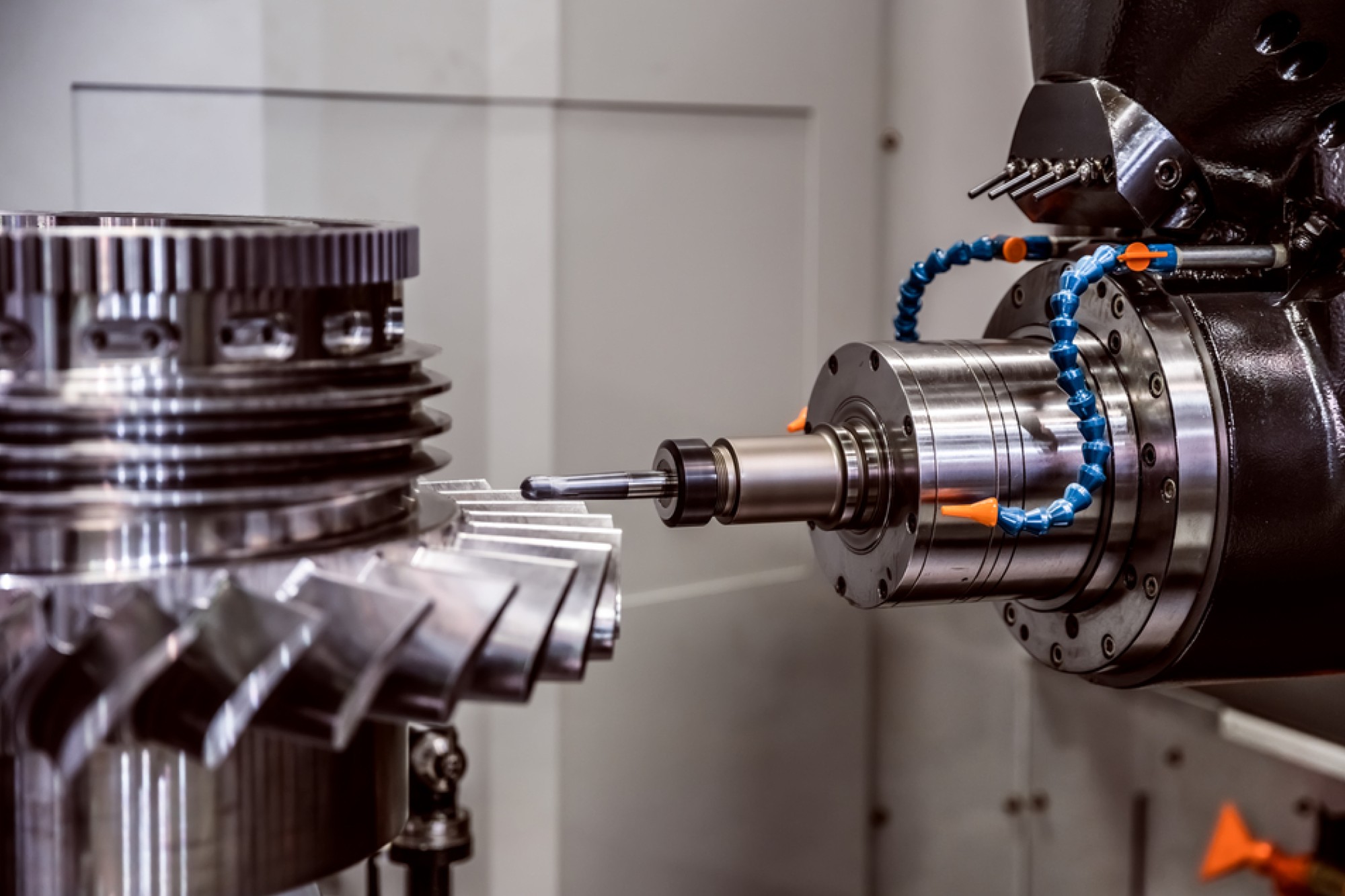

In an era defined by rapid technological change and market volatility, manufacturers face constant pressure to optimise production, reduce costs and maintain a competitive edge. The promise of Industry 4.0 is no longer a future concept—it is a present-day reality, and at its core lies the powerful combination of Digital Twin technology and Smart Manufacturing. For business leaders, these are not just technical upgrades; they are strategic imperatives for building a resilient, efficient and profitable future.

At its simplest, a Digital Twin is a living, breathing virtual replica of a physical asset, process or even an entire factory. It is a digital mirror that continuously receives real-time data from sensors and systems on the factory floor. This two-way communication creates a powerful feedback loop, allowing us to move

from reactive to proactive operations. It provides an unprecedented level of visibility, enabling us to simulate complex “what-if” scenarios, identify potential bottlenecks before they happen and make data-driven decisions at lightning speed.

For the business head, this means a significant reduction in risk and a clear path to continuous improvement.

This is the engine of Smart Manufacturing. By leveraging a cohesive architecture—like Delta’s suite of solutions, including DIATWIN, DIASECS, DIAEAP+ and DIASPC— companies can unify fragmented systems into a single, intelligent ecosystem. This integration breaks down traditional data silos between IT and OT, creating a seamless flow of information from the shop floor to the top floor. The result is a factory that is not just automated, but truly intelligent—one that can predict maintenance needs, optimise energy consumption and adapt dynamically to changes in demand. This operational agility is the key to maintaining profitability and supply chain resilience in an unpredictable global landscape.

Investing in these technologies is not about a massive, overnight overhaul. It is about taking a phased, strategic approach to digitalisation, unlocking value at each step of the journey . The initial returns are clear: enhanced quality control, improved operational efficiency and a significant reduction in unplanned downtime. Ultimately, the true value of Digital Twin and Smart Manufacturing lies in their ability

to drive sustainable growth and position a company as a leader in a dynamic, technology-driven market.

For any business head looking to not just survive but thrive, embracing this transformation is the only way forward.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.