Nord set up a global network of production facilities for all drive components

By OEM Update Editorial October 31, 2022 5:13 pm IST

In addition to standard drives, NORD supplies application specific concepts and solutions that fulfil special requirements such as energy-saving drives and explosion-proof systems.

Nord Drivesystems’s business activities

With approximately 5000 employees worldwide, NORD develops & produces a market-driven technology and is one of the industry’s leading international suppliers of all in one solutions. In addition to standard drives, NORD supplies application-specific concepts and solutions, including concepts and solutions that fulfil special requirements such as energy saving drives and explosion proof systems. Founded in 1965, NORD presently has 38 subsidiaries worldwide.

In India, incorporated in 2005, NORD Drivesystems Pvt. Ltd. is a 100 percent subsidiary of Getriebebau NORD in Germany. We have a full-fledged assembly unit in Hinjewadi, Pune, with a production capacity of 42000 units per year. We cater to the Pan India & SAARC country market.

Innovative and safe practices for the automated manufacturing of gears and motors

Our production facilities are located in Germany, Italy, Poland, the USA and China. The facilities have implemented the latest technologies for producing gear units, motors and drive electronics. The norms of highest quality standards at all facilities are followed with flexibility and dependability, considering customer benefits. The environmentally friendly production saves resources and is of vital concern to the management. Energy-saving leads to the high efficiency of products which are produced in environmentally and climate friendly plants.

Evolving trends for gears, motors and transmission segments

Post covid, the situation has changed, and the industry is moving towards more automation & efficiency improvement. In each sector, customers are looking for complete solutions. Here NORD plays a vital role with its Industry 4.0-ready products. Concepts like predictive maintenance are coming up in many industries, and NORD believes in offering these solutions with improved system efficiency.

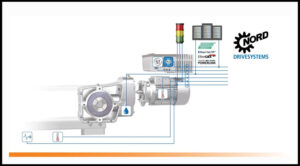

Decentralised frequency inverters

Our Decentralised drive is a unique product with a combination of gearbox, motor & inverters. The NORDAC FLEX, the all-rounder among decentralised frequency inverters, has established itself in almost all areas of engineering and industry. This is due to the wide range of available powers (up to 22 kW – which by no means is something that can be taken for granted in decentralised drive technology). The establishment in varied areas is also due to the wide selection of functions and the flexibility offered by its comprehensive range of accessories.

The series has been structured with various function levels to consider efficiency and customers’ application-specific requirements. In addition, we have arranged the series into two equipment groups which optimally cater for typical customer applications for conveyors, pumps and fans.Even, or mainly for applications in which a frequency inverter is not strictly necessary from a technical point of view (the constant speed with 50 Hz), the NORDAC FLEX beats every unregulated drive unit with its enormous energy-saving characteristics, particularly in partial load operation.

We are considered to be a technological leader in the development and production of motors, gear units and drive electronics, and we work to the highest quality standards. To comply with these standards, we have set up a global network of production facilities for all drive components. Our headquarters, with its technology and logistics centre and offices, is located in Bargteheide near Hamburg.

In addition, we have seven production facilities in Germany, Italy, Poland, the USA and China. Whether it is gear wheels, shafts, housings, motors or drive electronics – all components are produced in our production facilities with excellent dependability and flexibility. We, therefore, offer our customers the best possible quality, regardless of the location and circumstances throughout the world.

India, as a country producing machines, also has its consumption pattern. This stands to provide immense opportunities in the market. Presently, with automation and new markets opening up, we have a positive outlook on the growth of the drive systems market in the Indian market.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.