Sustainability setting new benchmarks in manufacturing

By Staff Report August 1, 2024 12:10 pm IST

Sanjay J Patel, Managing Director, states that Tembo Global is expanding its manufacturing and R&D facility in Vasai. The company aims to increase production capacity, drive innovation, and optimise operational efficiency to meet rising market demands, maintain a competitive edge in the industry, and set new benchmarks in manufacturing.

Could you discuss the rationale behind your shift into the EPC contract business and its impact on manufacturing?

Tembo Global’s strategic shift into the Engineering, Procurement, and Construction (EPC) contract business reflects a calculated move to diversify revenue streams beyond traditional manufacturing. Tembo Global can tap into lucrative opportunities from large-scale infrastructure projects by engaging in EPC contracts. These ventures typically offer higher profit margins and longer-term revenue stability.

Previously, Tembo products were utilised in projects, but now, by leveraging their established manufacturing expertise, Tembo Global can offer comprehensive, integrated solutions to clients. It enhances competitive advantage and attracts a broader customer base. This strategy will impact the manufacturing sector positively by encouraging innovation, fostering synergies between design and production, and driving technological advancements through cross-sector collaborations. Ultimately, Tembo Global’s EPC expansion positions them strategically for sustained growth and market leadership in manufacturing and infrastructure development. Tembo is collaborating with large corporates on various projects with L&T, Tata Projects, and Kalpataru.

How will the newly established manufacturing and R&D facility in Vasai enhance Tembo Global’s production capabilities?

Establishing new manufacturing and R&D facilities in Vasai allows Tembo Global to achieve its objectives. First, it aims to expand production capacity, ensuring the ability to effectively meet escalating market demands. Second, the facilities will serve as hubs for advancing research and development efforts, driving innovation in product design and technology.

By choosing Vasai, Tembo Global gains access to a skilled workforce and benefits from logistical and infrastructural support in the region. These initiatives enhance Tembo Global’s competitive position by optimising manufacturing efficiencies. They also help in product innovation and superior quality standards across their offerings. Tembo is exploring structural and mechanical fabrication for plants in the Oil and gas, Petrochemicals, Infrastructure, and Civil industries.

How will the Vasai manufacturing facility influence Tembo Global’s capacity and operational efficiency?

Expanding the Vasai manufacturing facility will enhance Tembo Global’s capacity and operational efficiency in several ways. It will allow for greater production output, enabling the company to meet the rising demands of its customers. This growth can lead to economies of scale, reduce per-unit production costs and improve profitability. The larger facility can integrate advanced manufacturing technologies and processes, increasing efficiency and minimising production downtime. With centralised operations in Vasai, supply chain logistics will be streamlined, reducing lead times and enhancing overall operational agility. The expansion of the Vasai facility positions Tembo Global to scale operations, maintain competitive pricing, and deliver products to market faster, thereby strengthening its market position and profitability.What milestones have been achieved by Tembo Global in the manufacturing domain over the past year?

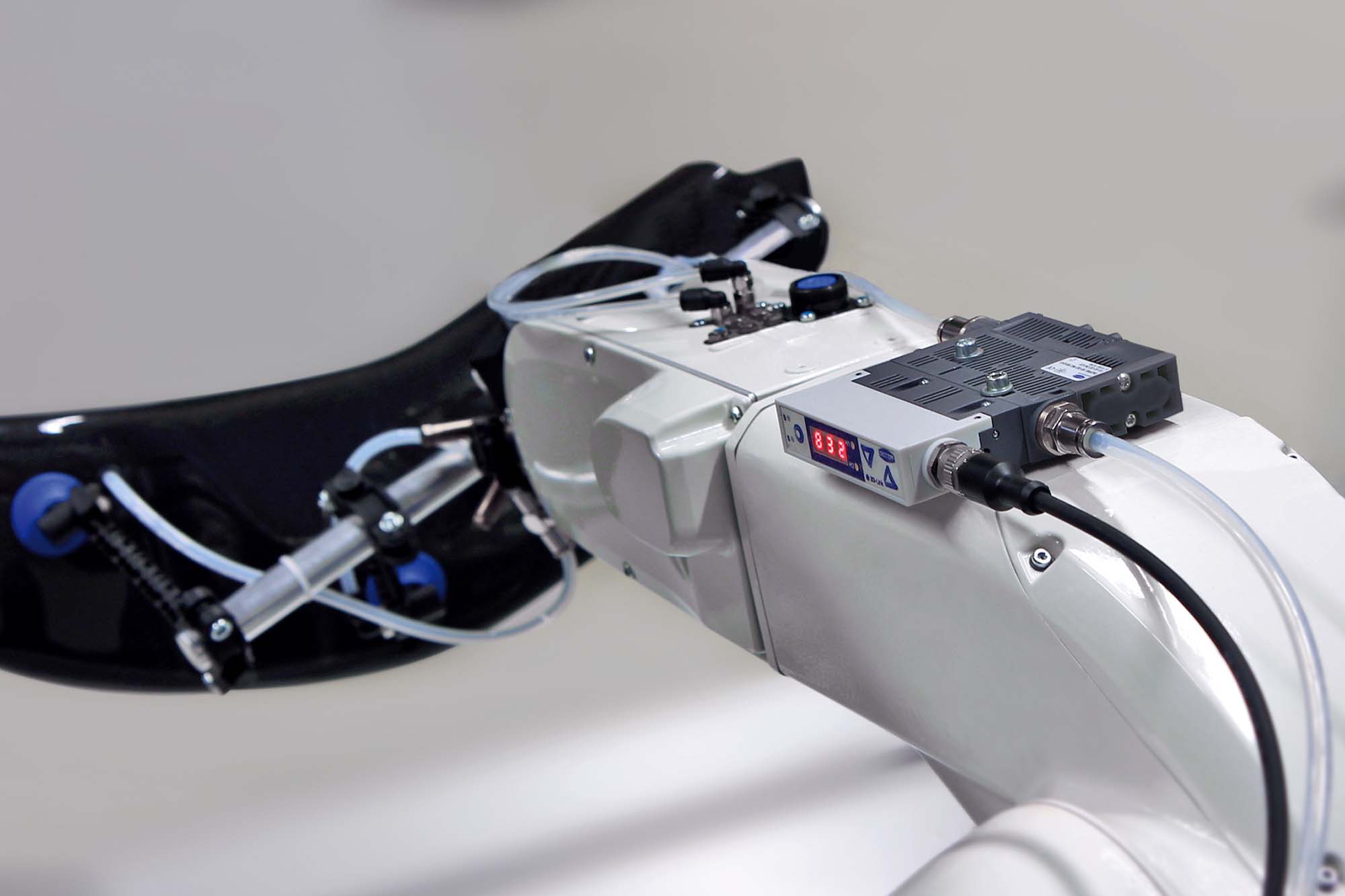

Over the past year, Tembo Global achieved significant milestones in its manufacturing operations. It launched a new line of modular support designed to fabricate manufacturing assembly and advanced products featuring cutting-edge materials and technologies to enhance performance. The opening of a modern facility in Vasai marked a strategic expansion, boosting production capabilities and operational efficiencies to meet rising market demands effectively.

Tembo Global’s adoption of lean manufacturing principles has driven improvements across all facilities, reducing waste and optimising resource utilisation. The commitment to sustainability is recognised with certifications for environmental management and ethical manufacturing practices, further solidifying their industry leadership.

What is your vision for the future of Tembo Global in terms of driving innovation and promoting sustainability?

The vision for Tembo Global in the manufacturing industry is to emerge as the foremost industrial powerhouse, producing metal products essential for Pipe Support Systems, HVAC, Anti-Vibration Systems, and Industrial, Commercial, Utility, and OEM installations worldwide. We aim to achieve this by leading through innovation and sustainability, pioneering advanced manufacturing techniques and materials that set new benchmarks in product performance and reliability.

Tembo is now venturing into the automobile, aerospace, and defence industries, aiming to set up advanced machinery for this sector. It explores options for joint ventures, technology transfer, and collaboration with European or American companies under the Make in India scheme. Tembo will integrate eco-friendly practices into operations, minimising environmental impact while maximising operational efficiency. By consistently delivering superior quality and innovative solutions, Tembo Global strives to establish a global standard in ethical manufacturing practices and sustainability, ensuring leadership in the industry.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.