Automated Test

By admin August 27, 2015 2:36 pm IST

Using NI software to develop automatic test equipment for helicopter gear boxes

Helicopter gear boxes must undergo extensive testing before use. To evaluate functional aspects of a helicopter’s main gear box (MGB), Hindustan Aeronautics Ltd. (HAL) team developed a special test facility where a gear box rotate from zero to full speed, then verify the functionality of pumps, bearings, the oil circulation system and freewheel actuation, and the de-actuation system.

The challengeDeveloping an accurate, reliable automated test system to evaluate the functionality of gear boxes with minimum setup time.

The solutionUsing NI LabVIEW software to create a reliable automated test system for airborne gear boxes using programmable signal conditioners and controllers.

Test requirements and setup Each gear box must be checked for lubrication oil distribution, leakages, and sump oil and bearing temperature stabilisation. It is also must to verify the actuation and de-actuation mechanism of the freewheel attached to the gear boxes. All of these tests are performed at the rated speed of the gear box.

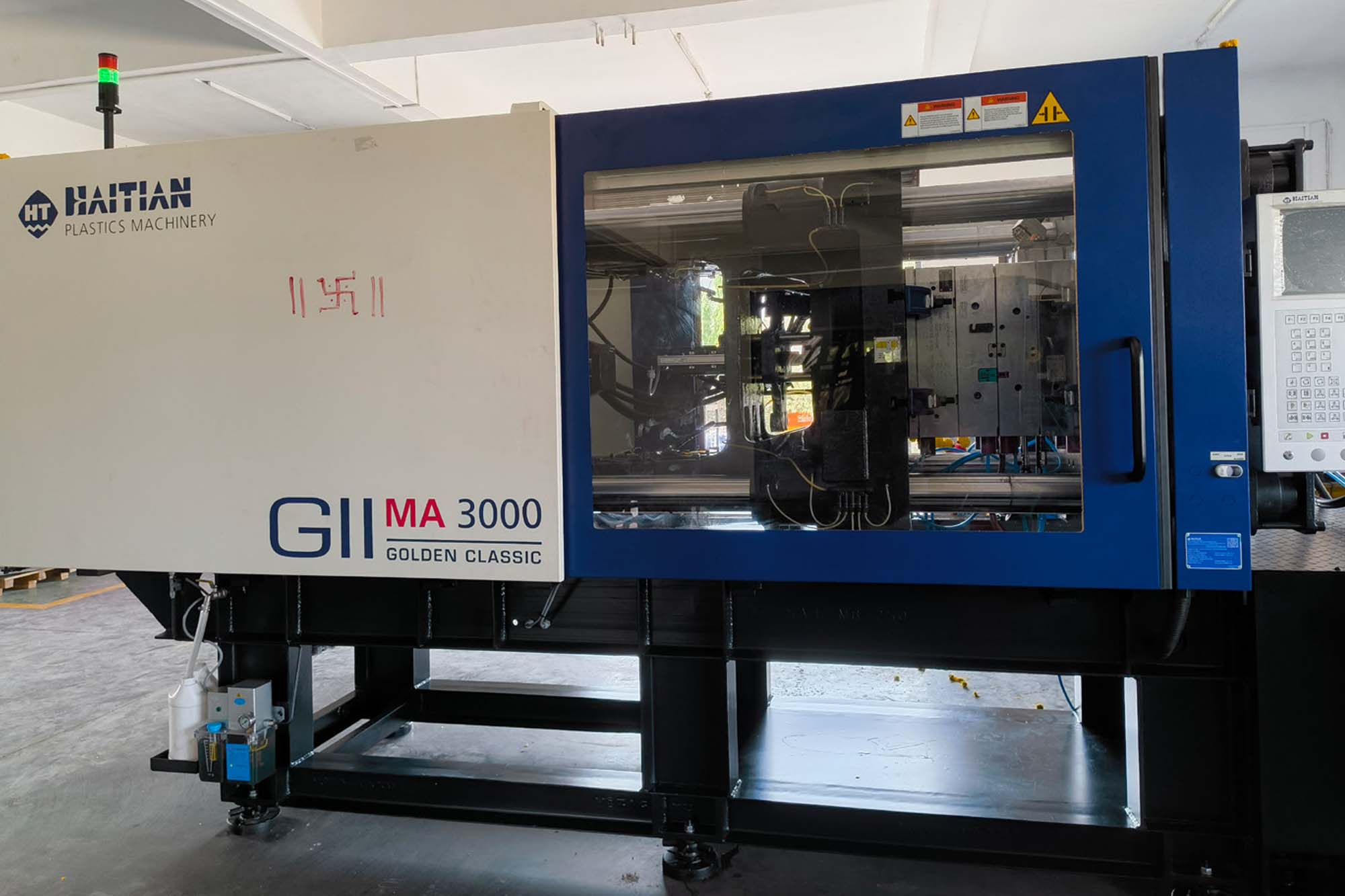

The test system consists of a DC motor, a drive system, a speed-increasing gear box, and a lubrication system (Figure 1).

Software requirements To successfully test the MGB, a system was needed to be developed to switch the lubrication system on for the speed-increasing gear box, check for pressure, check the health of the drive system and motor, and verify all sensors. If all subsystems are functional, the automation system starts the test in a particular sequence. Initially, the MGB rotates at a low speed. At this point, the system checks for leaks and verifies all MGB parameters.

After confirming the parameters of the MGB and test rigs are satisfactory, the automation system increases the speed to 100 per cent in 20 per cent increments. In each step, the system compares the parameters of the MGB with standard values. If values are not within the acceptable range, the system stops the test. Otherwise, speed increases to 100 per cent.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.