Digitisation opens ways to transform manufacturing

By OEM Update Editorial June 29, 2017 5:38 pm IST

Robotics and automation are no longer a good to have, but a ‘must-have’ in Indian manufacturing.

Higher OEE with digitisation

Industrial revolutions have been inevitable, right from the steam engines in the first, to line manufacturing in the second and robots in the third revolution. Today, manufacturing units needs to adopt digitisation for enhanced productivity and throughput. Manufacturing units have long wanted to achieve higher overall equipment efficiency (OEE) and with digitisation, the plant and factory operators are not only able to monitor but also improve on their OEE. The impact of intelligent automation is plenty. PV Sivaram, Managing Director, B&R Industrial Automation, said, “Reduced inventory, improved OEE, increased personnel flexibility reducing manufacturing costs, automated transport, reduced overhead for variants, production flexibility, real-time quality control cycles, optimised replacement part inventory, condition based maintenance and energy optimisations are a few to highlight.”

Digitisation awareness on the rise

B&R has always offered to Indian customers the latest offerings, because the company considers Indian machine builders to be every bit as innovative and open to new technology as elsewhere in the world. B&R provides complete solutions for machines, robotics and factories for achieving a successful IIoT and Industry 4.0 implementation for greenfield as well as brownfield. Also recognising that a product with high features is not sufficient, B&R focuses on having professional manpower who have mastery over the products, to help its customers to select and implement the new product and all features.

According to Sivaram, the market for automation in India is growing at least at double the rate of the world market. The awareness of smart factory, Industry 4.0 and the Industrial IoT is on the rise among the Indian manufacturers and OEMs too. Commenting on the preparedness of Indian manufacturing sector on digitisation, he says, “Today, we are seeing an increased rise in the awareness and requirement of technology by the Indian industry. They are eyeing for best-in-class performance at optimum costs.”

Sivaram further opines that today manufacturing not only looks at productivity in terms of quantity and quality but also in terms of OEE, energy monitoring, condition monitoring and machine and plant availability. He said, “Technology transition times from the developed economies have shortened. India no longer wishes to project itself as a low cost hub (China-model), rather wants to be best-of-class and preferred choice.”

In the context of the new industrial revolution, machine and factory builders are turning towards open source architectures and moving away from proprietary solutions to handle the rapid and asynchronous new developments in fields like processors, connectivity, mechatronics, Artificial Intelligence and enhanced reality. Openness also forms the core of Industry 4.0, smart factories and machines. “Robotics and automation are no longer a good to have, but a ‘must-have’ in Indian manufacturing,” claims Sivaram.

Geared up for smart factoryApart from products, it is the software playing an essential role in digitisation and is driving business value in this fourth industrial revolution. Hardware and software systems from B&R provide a platform for machine and plant builders to provide smart machines and factories. B&R with its hardware and software solution is an ideal partner for a successful Industry 4.0 implementation. Automation Studio, which is a single tool for all B&R systems, equips the users with the power of programming in all IEC 61131 languages and ANSI C and C++.

Machine and plant builders demand machine and process virtualisation in automation software at all levels of electronics. Automation Studio provides a simulation environment enabling the users to simulate the electronics without actual hardware. This reduces the time-to-market drastically. Automation Studio is capable of simulating B&R systems from HMI, controller, motion, IOs right down to motors. Its seamless connectivity with software’s such as Matlab and MapleSim has enabled machine builders to go one step further enabling them to simulate even machine mechanics coupled with B&R electronics. B&R thus, truly is an enabler for Digital Twin, providing machine virtualisation from process level to machines to mechanics, said Sivaram.

The future of automation lies in software. Recognising this, B&R has launched an absolute modern concept to develop machine software. mapp technology is one such innovation in recent times, which enhances software functionality and reduces the development effort by 67 per cent, claims Sivaram. “Thus, we believe that programming is the thing of the past and we look at configuration as the new way of application development. mapp technology integrates web with automation offering its customers a web based HMI and diagnostics right down to variable level.”

openROBOTICS has opened up new dimensions of robotics integration for machinery and production lines. With uniform programming for every component in the line – including robotics – B&R customers around the world gain full benefit of holistic approaches to operation, diagnostics and maintenance. B&R has already a successful implementation for a human robot collaboration application where the robot is not bounded by cage and works together with humans satisfying entire safety requirement.

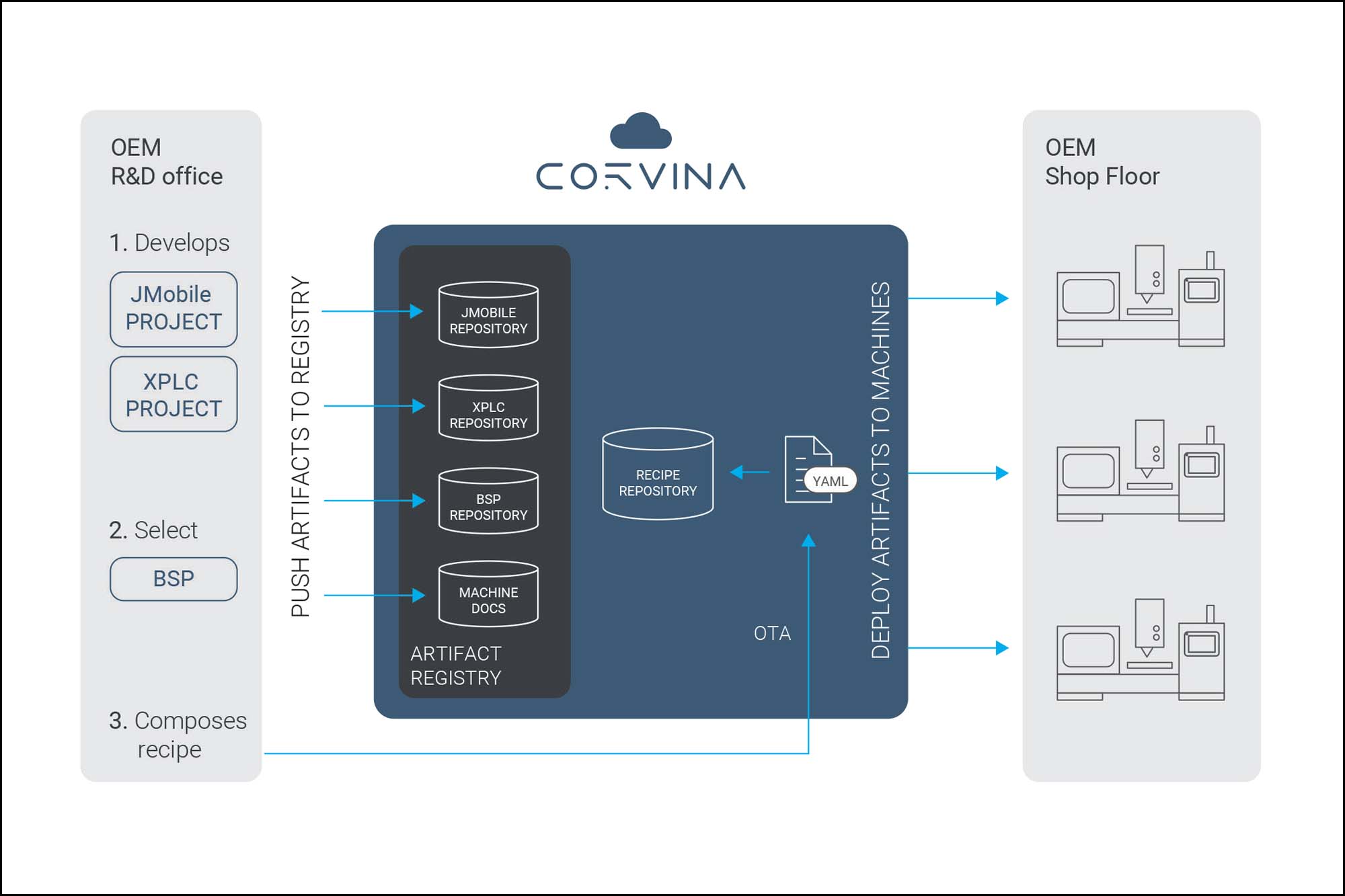

Smart machine and factories need to deliver Batch size-1 production systems and be able to offer mass customisation to its customers. B&R in its own production systems offers its users possibility to customise its high performance power panels and automation PCs right down to batch size-1, resulting in over 2 billion configurations to choose from. These machines are seamlessly connected to the ERP and MES systems. Thus, using B&R systems, machine builders are able to achieve batch size-1, mass customisation and connectivity from shopfloor to MES / ERP / cloud. Data from the shopfloor is available in abundance, but this data has to be converted to information and this needs a middleware. APROL, an open DCS platform from B&R acts as a distributed and independent middleware integrating applications from shopfloor with IT. With out-of-the-box, solutions such as energy monitoring, condition monitoring and advanced process control it provide a single system for all user needs, thus reducing costs.

Open architectures are very important aspects in smart machine and factories. B&R systems utilises open connectivity standards from sensors to the cloud – OPC UA for machine-to-machine and process to MES/ERP/Cloud connectivity, Ethernet POWERLINK for real time communications and openSAFETY for fieldbus independent, SIL3 certified communication. Smart machines and factories needs a 24×7 operation and needs high availability. B&R provides full transparency and connectivity at all levels. Plant and factory operators benefit from redundant – operator stations, OPC servers, runtime servers and runtime stations, process bus, gateway servers, controller and power supply.

Embracing digitisation

B&R has a state-of-the-art production of electronic modules which includes automated laser marking for serial number and certifications, automated 100 per cent functional testing tailored to each model, type and revision, assessment of OEE, preventive maintenance with automatically generated maintenance plans, informed Sivaram. He adds, “Assembly of system configurations include – individualised customer orders sent directly from ERP to production, workers guided by pick-to-light and pull-to-light systems, automated plausibility and configuration verification with more than 2,500 tests, condition testing with visual inspection and direct feedback to ERP and automated firmware installation.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.