Efficiency won’t come cheap

By OEM Update Editorial March 7, 2019 5:28 pm IST

Philippe Selot, Manager -Marketing Communication, United Grinding in an interaction with Athira of OEM Update gives an insight on how important it is for the Indian entrepreneurs to adopt technologies so as to sustain the future of their industries.

What products did you launchat the IMTEX 2019 exhibition?

We didn’t launch any new products at IMTEX. However, there is one machine from Walter Maschinenbau GmbH, which we showcased to the Indian market for the first time. It’s not a new product, as we have launched it in Europe already quite a while ago. But for the Indian market it is a new machine. We do have new products in our brand portfolio, but they were not exhibited at the IMTEX 2019.

What are these new products?

Fritz Studer AG, for instance, has a new range of products called “favorit” — it’s a universal cylindrical grinding machine rather in the entry level segment available in different sizes from 400mm to 1.6 meters, and it’s certainly one of the hot items at the studio for the moment. It has been launched in Europe. It will be launched in China in two months. In India, we will not have a launch event as such, but it will be available in the Indian market as soon as there are enquiries.

Why no launch?

The Indian market, although being an important market, is not that big that it would justify a launch of a new product in India. For us, the Chinese market is, with all due respect, far bigger than the Indian market.

One main concern is that the Indian MSMEs are not so welcoming in adopting technologies. What message would you like to give the Indian industries so as to let them know that technology is what will take them forward?

To start with let me compare the development of China and the development of India. China, as you know, started years ago to overload the world market with cheap products. They were not only cheap in terms of price, but they were also cheap in terms of quality and performance. Meanwhile, China has discovered or realised that they want to be a worldwide player.

On the long term, quality is an issue. We can exactly do the same parallel comparison with Japan. I remember in my very young age; a Japanese car was really nothing that exciting. Nowadays, Japan is one of the top manufacturers of automotive car, incredibly reliable, top quality.That’s exactly the point;if you want to be among the big players today,you need to satisfy the customer’s requirements with quality products.

How do you gauge India as a price sensitive market?

If you look at our market here in India, Indian customers are very eager for new technology, for high performance products. But then, when we talk about price, they opt for the cheaper one. What we need to understand is that high technology or high efficiency machines are not the cheapest.

I’m clearly saying that we don’t need only engineers, we need also good skilled operators, which are not at an engineer level; an engineer will not necessarily run or operate a machine. But to operate a machine you need manpower who knows what they are doing, how to operate, how to make the product that they are manufacturing as efficient as possible. This is also something where India should consider that beside the high-end education doesn’t forget the training about a big mass of people.

Is there any initiative that United Grinding is taking up to spread awareness or coaching people to be more receptive towards adopting technologies?

This is very internal and European point. In Europe, we have so-called apprentices. They do four-year training, half the time in a company and half the time in a school. There is an organisation called World Skill or the Apprentice Olympics, and there you have young people.I think that underlines that we are really focusing very strongly on education of our young generation. This is crucial for the fundamentality of the future. If you build a house on a sandy ground it would not last. But if you build it on a solid ground it will last.

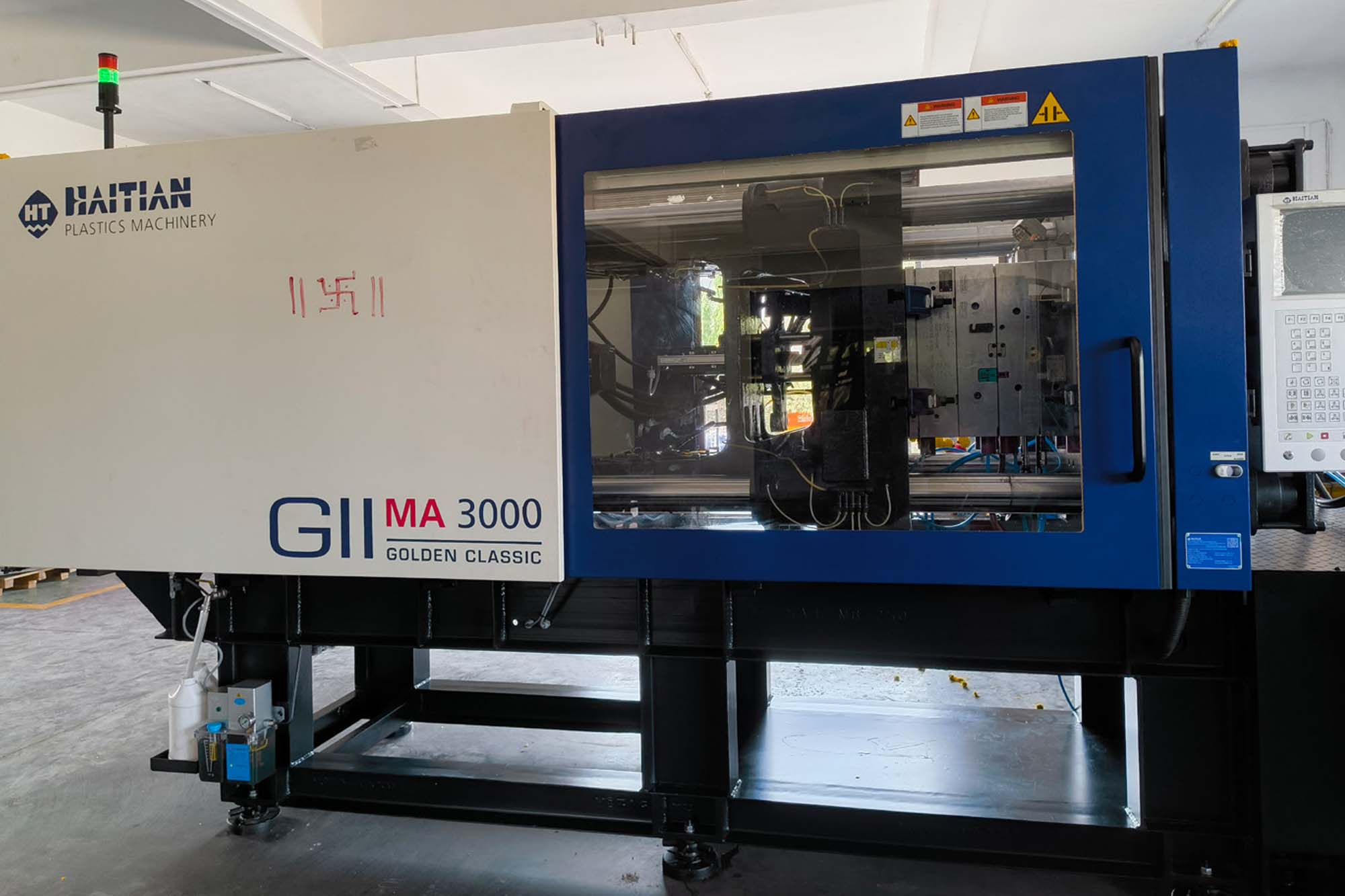

Digital transformation’s societal impact on industry

United Grinding, being based in Europe, has a very strong partnership with German machine tool association and there we’re a leading member of the fine and new interface for Industry 4.0. That underlines our strength in new technology and development of new things. Industry 4.0 is of course the fourth revolution in the industry. But, it will certainly not be quickly implemented as it was with Industry 1.0 or Industry 2.0, it will last a little longer. However, there’s no doubt that it will happen. If you just think about 10 years ago, nobody had a mobile phone. And when the first mobile phone came out, you could barely dial a friend. Nowadays, with a mobile phone you do banking, book your holidays, take pictures, use social networks, you can do any and every kind of things. The exact same thing will happen in the machine tool as well. Although not quickly as in the sector of mobile phones, but it will happen. This technology is of course not free of charge and then comes the question “when will the market be ready to do the investment”, the basic investment to make themselves more efficient”. For example, consider a machine with a loading system. Now in India, I’m always told that we don’t need loading system because there is a lot of labour, which is very cheap; therefore not willing to invest in an expensive loading system. I fully understand that statement. But when that labour has to go for lunch or goes home in the evening, the machine is idle. And the machine is a very heavy investment. You cannot, in today’s economical environment, have such a high value investment to be idle. This is not efficient. So to overcome that, a loader could eventually be an alternative. But the loader is not a solution that will run 24 hours a day.

So, when the machine runs, and you sit at home and watch cricket match, the mobile phone can eventually inform you “Listen! Now the loader is empty. Somebody should go to the factory to reload the magazine to carry on working” so that your machine will have a short idle time as possible. This is one of the forms of Industry 4.0. There is an interaction between the machine and the operator at any time. It’s a philosophical approach.

If you look at our market here in India, Indian customers are very eager for new technology, for high performance products

Philippe Selot, Manager- Marketing Communication, United Grinding

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.