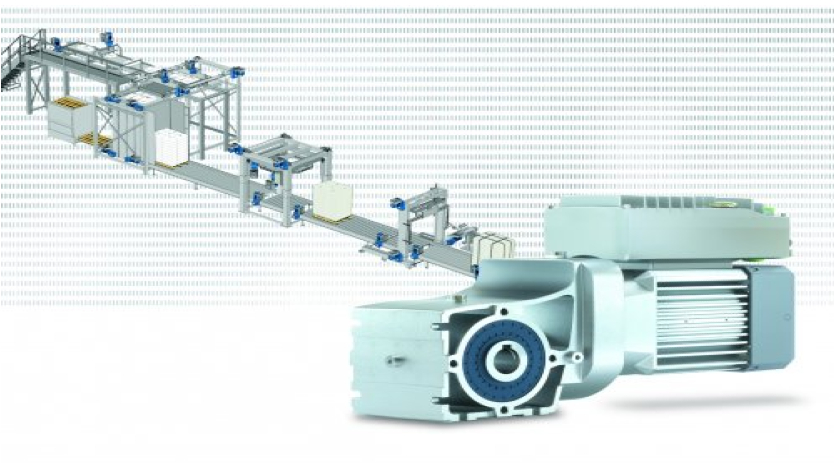

End-of-line packaging: Decentralised drive technology with controlled frequency

By OEM Update Editorial May 4, 2023 5:00 pm IST

Heavy loads, high forces, long travel distances and lower requirements for precision and dynamics are characteristic for end-of-line packaging. The use of decentralised drive solutions with controlled frequency inverters can achieve cost benefits of up to 50 % depending on the type of system and application.

Drives with centrally controlled servo motors are commonly used in end-of-line packaging. However, in applications with large inertia or long movement distances – for example palletising, stabilising or handling – they are usually not mandatory. Decentralised drive solutions, for example with controlled asynchronous motors, are an efficient and economical alternative in this context. NORD DRIVESYSTEMS is highly familiar with the industry’s requirements and implements modular drive concepts that are precisely tailored to the specific application and customer requirements.

Asynchronous motors with decentrally controlled frequency inverters.

Due to their high inertia, NORD asynchronous motors offer decisive advantages for end-of-line packaging. When moving heavy loads, it ensures better (movement) control than conventional servo solutions that must be adjusted to the respective application via large gear ratios. Furthermore, they enable highest process stability, reduce vibrations and the risk of damaging the load or packaging machine. A further advantage: asynchronous motors are available everywhere in a wide range, are easy to maintain and can be combined with different types of gear units and frequency inverters.

With a modular concept, the drive also remains maximally flexible, as changes to the system architecture can be made at any time without large structural modifications, and additional drives can be easily added later without changes to the control cabinet.

Cost benefits of up to 50 %

Low procurement costs, constructive freedom in machine design, faster commissioning, simplified maintenance and repair processes: asynchronous motors with decentrally controlled frequency inverters and encoder feedback via absolute or incremental encoders enable highly economic and precise positioning applications and dynamic movement of large and heavy packaging units. This makes this technology a real alternative for application fields such as end-of-line packaging, where heavy loads and high forces are the norm. Depending on the system type and application, the savings can amount to up to 50 %.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.