Let the ‘good times roll’ with Renishaw’s 5-axis CMM inspection

By admin July 16, 2015 12:47 pm IST

At the Maryville plant of Kawasaki, 5-axis scanning probes speed form-data collection and feedback to machining cells, reduce CMM fixturing and cut probe calibration time from hours to minutes, while ultimately eliminate inspection systems for gears and cam lift.

Kawasaki encourages motorcycle enthusiasts to “let the good times roll,” but good times of another sort are rolling at the company’s Maryville small engine plant, where two 5-axis scanning probe systems are slashing CMM inspection and probe calibration times, and speeding up QC feedback for machining of small engine components.

The 5-axis Renishaw REVO systems, installed on Mitutoyo Crysta-Apex 121210 CMMs, replaced two PH10 articulating heads using SP25 scanning probes on traditional 3-axis CMMs. The REVO-equipped CMMs have cut inspection times by half or more on scanning intensive applications, eliminated the need for custom probe configurations, cut probe calibration times from six to seven hours to about 45 minutes, and added new capability to collect large amounts of form measurement data, improving part quality. Of primary importance, the REVO systems have greatly increased inspection throughput, data quality and flexibility of the QC department, enhancing its value as a strategic support asset to both manufacturing and R&D.

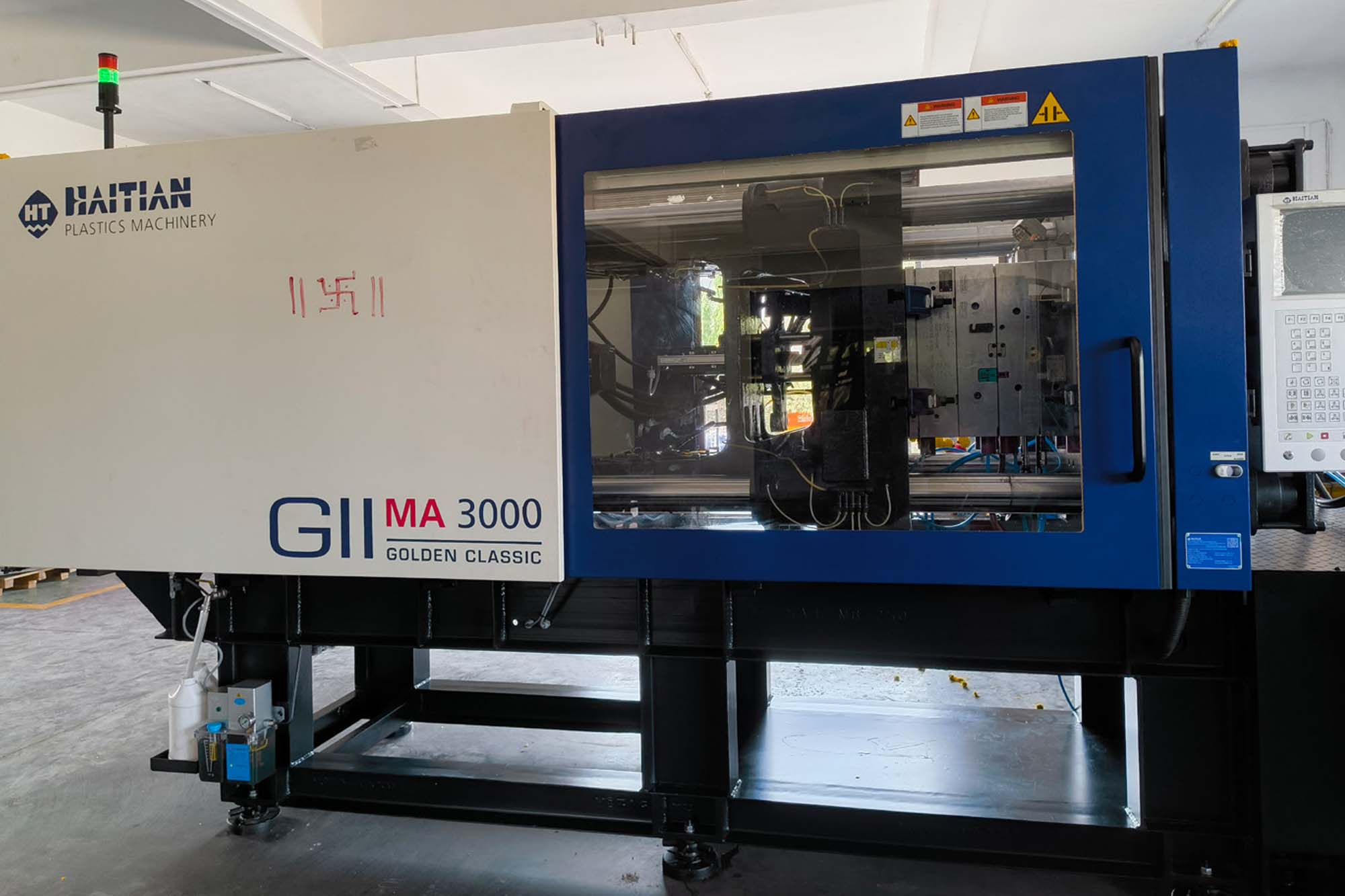

The Kawasaki Production SystemKawasaki’s 800,000 square-foot Maryville plant, opened in 1989, produces single and twin-cylinder air-cooled or water-cooled engines, 1000 cc or smaller, for commercial and consumer lawnmower OEMs, as well as for a sister plant that manufactures ATVs and Mule utility vehicles. Operations at Maryville include aluminium die-casting, plastic injection moulding, and extensive amounts of machining, painting and assembly. All engines – approximately 500,000 per year – are run-off before shipping as well.“We use the Kawasaki Production System (KPS),” said JC Watts, Quality Control Technical Group Supervisor at the Maryville plant. “Our quality and engineering requirements are comparable to the best in the automotive industry, though our manufacturing is focused on lower volumes of many different kinds of products.” The plant has 50 machining lines, typically arranged in a U-cell pattern with start and end machines across from each other. “Primarily, it’s one-piece production with machining lines running a part through multiple processes at a high rate,” Watts explained. Kawasaki utilises automation in many die cast and some machining operations, accomplished through the integration of Kawasaki robots. On one of the crankcase lines, robots load raw materials and unload finished parts that are placed into inventory for assembly to draw upon. Machined parts include aluminium, cast iron and steel.

“We’re running similar tolerances that automotive powertrain uses for high-end products, and there are probably four or five critical processes for our aluminium parts and 15 for the steel parts,” Watts added. It is not uncommon to find tolerances “in single digits in microns” for form, and 0.05 mm true position.

The QC lab is responsible for inspecting 125 different mass-produced parts, as well as vendor parts and those produced for engineering development. The environmentally controlled lab is located adjacent to the machining lines, and parts intended for routine inspection are delivered on carts or via train (an electric vehicle towing several trolley carts). Critical components may be hand delivered for priority inspection during a line changeover or if an operator suspects a problem.

5-axis scanning advantage“When I started here, we had a couple of 3-axis CMMs with PH10 articulating heads and SP25 probes, and another CMM with a fixed probe head,” Watts explained. “We were frustrated with having to make probe configurations and being limited to what we could do even with the articulated heads. We had so many different probe configurations that calibration times of six to seven hours took a bite out of our inspection throughput, too. We wanted to do better than what the industry considered the norm, so we looked at several options and the 5-axis REVO system appeared to be the fastest and most flexible available. It was the best fit for our requirements.” Kawasaki bought a new Mitutoyo Crysta-Apex 121210 in 2009 with the REVO system installed from the factory, and retrofitted an identical machine in 2010, after the first machine was up and running with all the part programs.

The REVO 5-axis scanning probe head can collect up to 6,000 data points/sec. It is engineered for high-speed precision measurement of contoured surfaces and complex geometries requiring high-volume data collection to validate fit and form with high accuracy. It uses two rotary axes, one in the vertical plane and one in the horizontal, for infinite rotation and positioning. Five-axis software drives the measuring head and synchronises its motion with the linear axes of the CMM. Look-ahead algorithms drive the probe path and CMM in coordinated continuous motion. The head adapts position while measuring on the move, maintaining stylus tip contact with changing contours at scanning speeds of up to 500 mm/sec.

“Though our SP25s were scanning probes, we were doing 95 per cent touch probing because scanning was too slow with a 3-axis CMM,” Watts explained. “Our cylinder and crank bores are probably the best examples of where we believed touch probing was inadequate. To accurately collect enough data points to measure the geometry of a bore 80 to 100 mm in diameter and 150 mm in length, the SP25 probe took so long we limited those inspections to machine set up or special requests from our design department. Now on every crank case we measure, the REVO does a spiral scan of bores and the system outputs the values to software. We also send a graph of the data points to our network that can be used by anyone in QC, engineering or production, and it really helps troubleshoot problems. You can VISUALISE the problem. What would take 3-4 minutes with an SP25, we’re measuring in 10 seconds with the REVO.” The REVO scanning heads have all but eliminated the need for touch probing. Now 95 per cent of inspections utilise scanning, with no “time penalty” as before, allowing Kawasaki to collect so much data that it challenges the speed of computers doing the analysis. The REVO probe can also do “head touch” probing or be used for traditional machine-touch probing when the situation calls for touches.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.