Remote firmware updates for industrial iot edge

By Staff Report June 19, 2025 6:33 pm IST

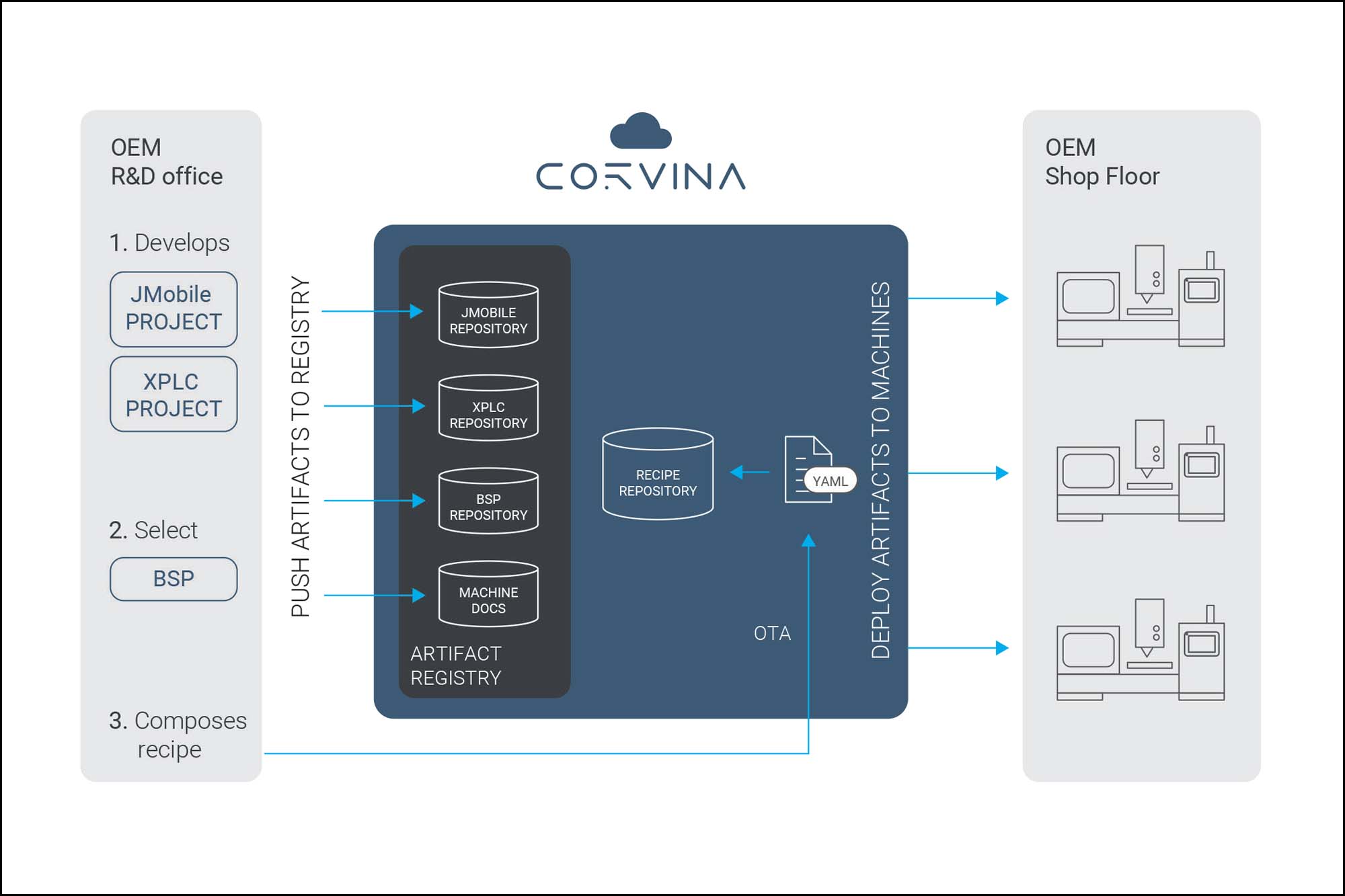

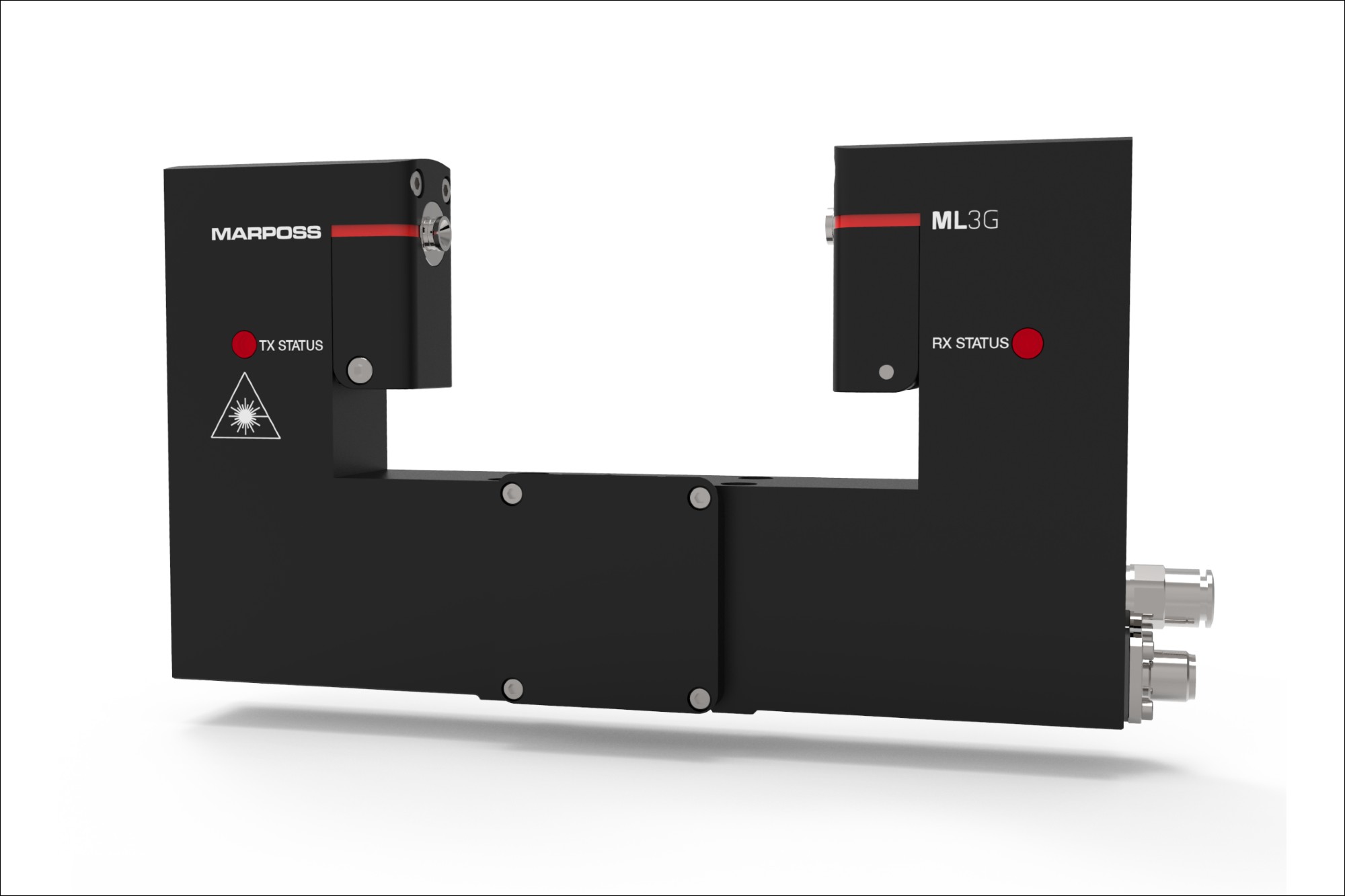

A user operates a network of IoT-enabled machines across factory floors to monitor and control production lines. As these devices are distributed across various locations, manual updates and maintenance become time-consuming and costly. Regular deployment of BSP (firmware) updates and software patches is crucial for addressing security vulnerabilities, enhancing functionality, and improving machine performance—ensuring optimal efficiency and reliability.

Solutions with Corvina Edge Manager

Leveraging the Over-the-Air (OTA) capabilities of Corvina Edge Manager, users can efficiently oversee and update all its IoT Edge devices from a single, centralised platform. The procedure includes the following step.

Remote device monitoring & diagnostics: The company can track the version of each software and firmware installed on Edge in real-time through Corvina’s Edge Manager dashboard, which provides easy identification of devices that need updates or maintenance.

Over-the-Air updates: Instead of sending technicians to update each device physically, the Corvina CEM OTA system enables users to securely deploy firmware and software updates to all devices across the factory floor with just a single mouse click. Updates can be run immediately or scheduled during off-peak hours to minimise disruptions to production.

Corvina Edge Management streamlines the update process, ensuring devices across the factory stay current, secure, and efficient without disrupting production.

Automatic and secure deployments: Corvina ensures the OTA updates are encrypted and authenticated, maintaining the integrity of the updates. Additionally, rollback features enable the company to revert to previous versions in the event of any issues.

Scalability: With thousands of IoT Edge devices in use, the OTA system supports bulk updates, ensuring all devices, regardless of location, stay up-to-date with the latest firmware and software without requiring manual intervention.

The following procedure reduces operational downtime due to faster and more efficient updates. It minimises the need for on-site maintenance, saves costs on travel and labour, enhances security with the latest patches deployed automatically, and increases the device’s longevity and performance through regular updates.

The X Platform world

The X Platform exists to bridge the gap between the aspirations of machine builders and the realworld needs of factory owners in the industrial automation sector. The platform serves as a comprehensive toolbox, helping users address current challenges while preparing for future ones.

The X Platform is a partnership, not merely a partnership. It empowers users to tailor solutions to the specific challenge at hand, ensuring they remain at the forefront of industrial innovation. The goal is to give machine builders the freedom to focus on what they do best: creating outstanding machines that meet the needs of factory owners.

Need of the hour-

Edge Security – Helps protect your data and business.

Remote access & VPN – Simplifying system integration, providing users with the ability to monitor and adjust processes anywhere.

Edge management – Making updates remotely, thus saving time and resources.

Tomorrow’s Want-

Remote and condition monitoring – Giving users the tools for proactive diagnostics.

OEE & Energy Efficiency – Monitoring and managing resources for sustainable growth.

Performance consultancy – Offering insights into optimising machinery’s potential.

Future Vision-

Marketplace integration – Creating potential channels for resource and information exchange.

Virtual Logic Control – Preparing for the Possibilities of AI-Driven Process Enhancements.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.