Smart edge for industrial cloud systems

By Staff Report September 12, 2025 6:21 pm IST

Cloud systems are evolving with intelligent edge devices for faster processing, improved security, and agility in industrial environments. Exor delves into the cloud system and how it can give a smart edge in industrial settings.

Cloud systems are now being built to work with smart devices at the edge of the network. These devices need to process a huge amount of data instantly, which is bringing back a distributed computing approach. This article talks about the cloud system assisting in learning, and the last point of long-term data storage, with most of the processing needs being handled at the edge. This trend is so dominant that it will also occur in the industrial world with more intelligent edge devices.

Some experts in the industrial sector believe that, regardless of IoT trends, physical devices will need more processing power.

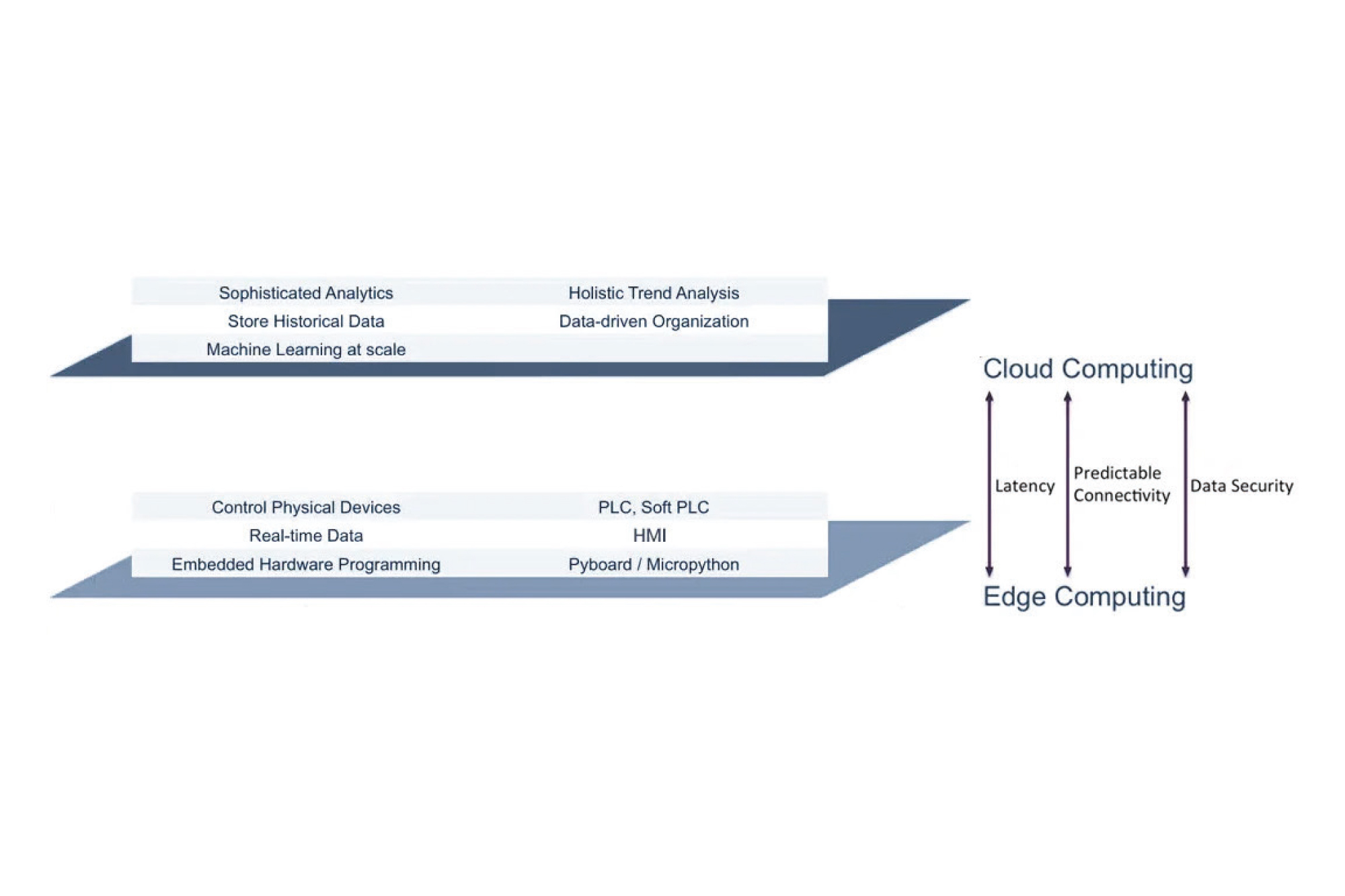

Using the table above, industrial advocates of the intelligent edge state that latency, predictable connectivity, and data security are among the key reasons. Let us look at each of these reasons:

Latency has been a tremendous issue for the industrial world, but it can change going forward as and when Time-Sensitive Networks become commonplace. However, there are no agreed-upon standards, and even when they are established, this will only affect greenfield sites. Brownfield sites will remain in this sector for many years to come.

Predictable connectivity is also breaking down as an obstacle, as the standard of communication, OPC UA, is becoming popular in machines. The old, closed proprietary protocols that the larger companies have attempted to maintain are giving way to more open systems of communication. However, this refers more to greenfield sites than brownfield sites, and the adoption cycle will last a few more years yet.

With data security, it is simply true that when data processing takes place closer to the edge source, and all other factors remain the same, the chance of data security breaches is lower.

Although the main reasons for a smarter and more intelligent edge offered by some industrial elements are being replaced with new technology, it is nonetheless correct to say that these new communication and standard protocols are yet to be fully delivered to the market.

What exactly does smarter or more intelligent mean? To answer this, we will refer to the work of Peter Levine, the renowned IoT investor.

Inside the Edge

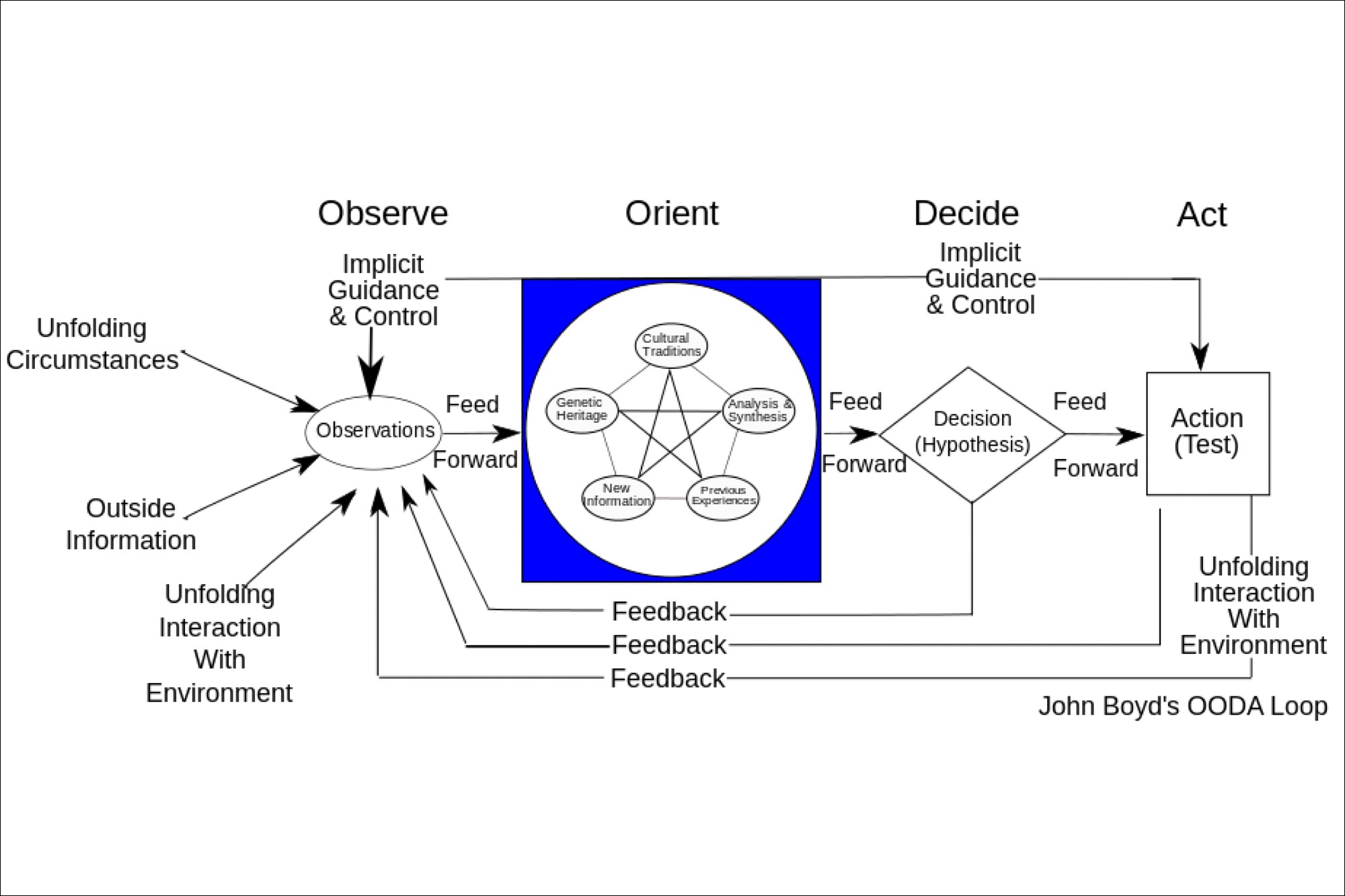

To explain the workings of future edge devices, Peter speaks of a system of training for US fighter pilots called OODA. The OODA loop is the decision cycle of observe, orient, decide, and act, developed by military strategist and United States Air Force Colonel John Boyd. Boyd applied the concept to the combat operations process, often at the operational level during military campaigns. It is now also often applied to understand commercial operations and learning processes. The diagram of this system shows parallels to the information systems required at the edge in industrial environments.

He believed that if this system could be taught to fighter pilots as a loop and then practised to reduce the loop time, then they would win every dogfight. The most important point about the system was that it prioritised agility over power, which is the same in the new paradigm to which we are moving in the IoT world. The endpoint device is nowhere near as powerful as the cloud, yet it is far more agile, and it can operate very quickly because the edge device processes only the information it needs.

The sense, infer and act loop at the edge is identical to the observe, orient + decide, act loop.

The edge, the intelligent edge, is all about agility – taking in the real-time data and processing what it needs. Real-time data brings the need for universal connectivity via the vast number of Industrial protocols that currently exist, while going far beyond the current situation. There will be an increasing requirement for the ability to sense the environment in which the edge device finds itself. This capability starts with sensors for:

- Temperature

- Pressure

- Humidity

- Voltage

- Gyroscope

- Altimeter

As well as:

- Camera for facial recognition,

- Wifi and Bluetooth for flexibility in connecting to networks and other mobile devices.

In a future where sensors will be everywhere, from autonomous cars to common factory floor equipment, there will be a need for a focal point to collect this sensor data, check parameters, and take possible action before sending only surplus data to the cloud for long-term storage (Sense–Infer–Act). It is easy to see that the edge device, once known as a Human Machine Interface, will need to become truly interactive: The Intelligent Edge.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.