Testing of water parameters at textile plant

By admin July 16, 2015 11:35 am IST

Technology has enabled efficient treatment of effluent waste for the textile industry in India, to prevent local water bodies from getting polluted

The textile industry in India has had a steady growth rate since the economic liberalisation in the 90’s. It is the second largest exporters of textile in the world and is expected to become the largest exporter of textile material to the world. The Indian textile industry which is mainly concentrated in Tirupur in Tamil Nadu, Surat in Gujarat and Ludhiana in Punjab and other parts of India has been exporting clothing material and readymade garments to several countries across the world. India has its place in the world when it comes to quality clothing being exported to foreign countries and being branded and sold there. However, a few years ago the government had laid several rules and regulations on the textile industry in India. Since 2008, several amendments and changes in laws and the turbulent global market forced several textile factories in India to shut down. An important thing to look at was that the effluent treatment in the textile factories was not done properly leading to pollution of local water bodies beyond the given limits. For several years, the local textile industries in India have continued to give quality and cost effective clothing material to India and the world. However, as a result of ecological factors around the world, a new government regulation made it mandatory for textile companies to make sure that they treat their effluents before letting them off into local water bodies. In this article, Kondiba Metkari, Business Manager, Hanna Equipments India shares his views on the treatment of effluent wastes in the textile industry giving us insight on the various technologies that Hanna Equipments India has to offer.

Textile industry – significant contributor to the exchequer Since the economical liberation in 1991, India has been constantly developing its industrial sector. Textile industry plays a major role in Indian economic. India earns 27 per cent of its total foreign exchange through textile exports. The Indian textile industry is presently estimated to be at around $ 108 billion and is expected to reach $ 141 billion by 2021. After the agriculture sector, Indian textile industry is the second largest employer that has generated huge employment for both skilled and unskilled labour alike. Textile companies are mainly located in Tirupur and Karur in Tamil Nadu, Surat in Gujarat, some part of Punjab, and Maharashtra region.

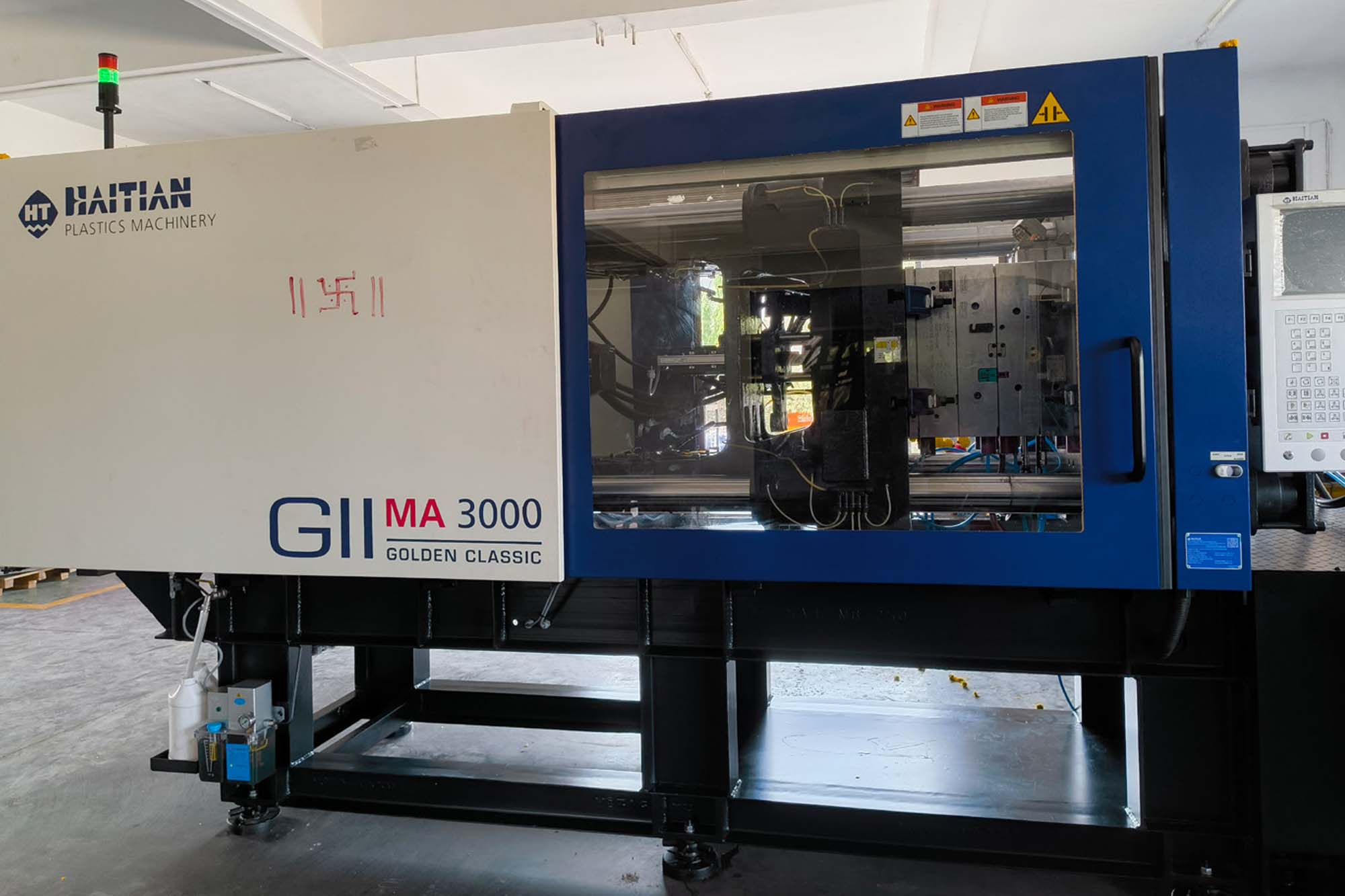

Textile industry is water intensive The textile industry is very water intensive and thus it produces huge volume of waste water. Textile manufacturing process includes sizing, desizing, scouring, bleaching, mercerising, dyeing, and finishing. The main release of pollution during manufacturing occurs during the dyeing and finishing processes. Dyeing and finishing processes account for 90 per cent of the total textile wastewater. Dyeing and finishing requires wide range of chemicals and dyestuff, chemicals such as acetic acid, sulphuric acid, sodium hydroxide, hydrogen peroxide, sodium hydrosulphite, phenyl phenols etc and others. These chemicals are dangerous and can have a high environmental impact if not treated effectively before discharge.

Government regulations on industrial effluents have become strictIndian government has made strict rule for releasing waste water in environment and these rules are mandatory for all manufacturing industry. As per government act for environmental protection of 1986, waste water should be treated before it is released back to the environment. For manufacturing and processing unit there are certain restrictions on the disposal of effluents in land, marine and in irrigation land. Textile industries have to pay attention to control the following critical parameter before discharging. A combination of technology helps to measure and test the waterThese parameters can be tested in laboratory, on field or directly during the inline process. Most textile manufacturing units rely on all three options. Customer now wants an instrument that not only measures all the parameters, but also records and saves data for analysis and audit purposes. Different testing methods and technology are now available, namely photometric method, chromatography, titration method, Ion selective electrodes and inline testing. Hanna Instrument helps textile manufacturers to find out the contents in the water. Hanna offers instruments for lab analysis, field analysis and inline testing. Hanna offers more than 3,000 products to industries across verticals. The R&D teams at Hanna continuously strive to develop new techniques that simplify the testing procedures. Hanna has products for testing major parameters of water. This includes parameters like pH, conductivity, and turbidity, TDS, ammonia, COD/BOD, dissolved oxygen, chloride, ammonia, various ions and many more.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.