Thriam Toolroom provides all solutions under one roof

By Staff Report June 19, 2025 6:16 pm IST

Thriam Toolroom combines all plastic product manufacturing expertise under one roof, offering a synergistic model that streamlines the entire product realisation process. Toolroom’s state-of-the-art facility ensures that production can commence without unnecessary pauses.

In-house moulding in plastic component manufacturing

When you are dealing with product development, every single day saved can give you a competitive edge. For businesses in the world of plastic components, the journey from an initial concept to a finished, the marketable product often involves two distinctly linked stages: the creation of a precision mould and the subsequent moulding of parts. Traditionally, these tasks are handled by separate entities – a dedicated toolroom and an independent moulding facility. While this fragmented approach may seem like a standard, it often introduces hidden delays, communication breakdowns, and logistical nightmares that can severely impact project timelines.

Forward-thinking companies recognise the profound time-saving benefits of partnering with an integrated toolroom that also boasts in-house moulding capabilities. This synergistic model streamlines the entire product realisation process, offering an unparalleled path from design to mass production. Thriam Toolroom is a prime example of how combining all plastic product manufacturing expertise under one roof delivers undeniable advantages.

One of the most immediate and impactful time-savers is streamlined communication and unparalleled collaboration. When mould designers, toolmakers, and moulding engineers operate within the same facility, traditional communication barriers vanish. The structure of Thriam Toolroom ensures that all stakeholders are on the same floor. This proximity facilitates real-time discussions, instantaneous feedback loops, and rapid problem-solving. Misinterpretations that could cost days or even weeks in a fragmented system are swiftly addressed, ensuring that the mould design is perfectly aligned with manufacturing requirements from the outset.

This integration accelerates the prototyping and iterative development process. Once a mould is crafted by the toolroom, it doesn’t need to be packaged, shipped, and scheduled for trials at a separate facility. Instead, it can be moved directly to an adjacent moulding machine for immediate testing. This capability is where they shine. Their comprehensive 15-step mould manufacturing process, coupled with immediate access to their moulding capabilities, allows for swift first-shot evaluation. If there are any design flaws, moulding problems, filling issues, or cooling inefficiencies, the mould can be quickly sent back to the toolroom for fixes. This rapid iteration cycle compresses development timelines, preventing the costly and time-consuming back-and-forth typical of outsourced scenarios.

Furthermore, an integrated facility provides superior quality control and reduced risk. The toolroom can immediately assess the performance of newly built moulds by producing actual parts. This enables real-time validation of part quality, dimensional accuracy, and overall moulding process integrity. Since Thriam Toolroom is equipped with advanced CMM (Coordinate Measuring Machine) capabilities and rigorous quality checks at every step, it can make precise adjustments to the mould on the spot, guaranteeing that it consistently produces high-quality parts right from the first production run.

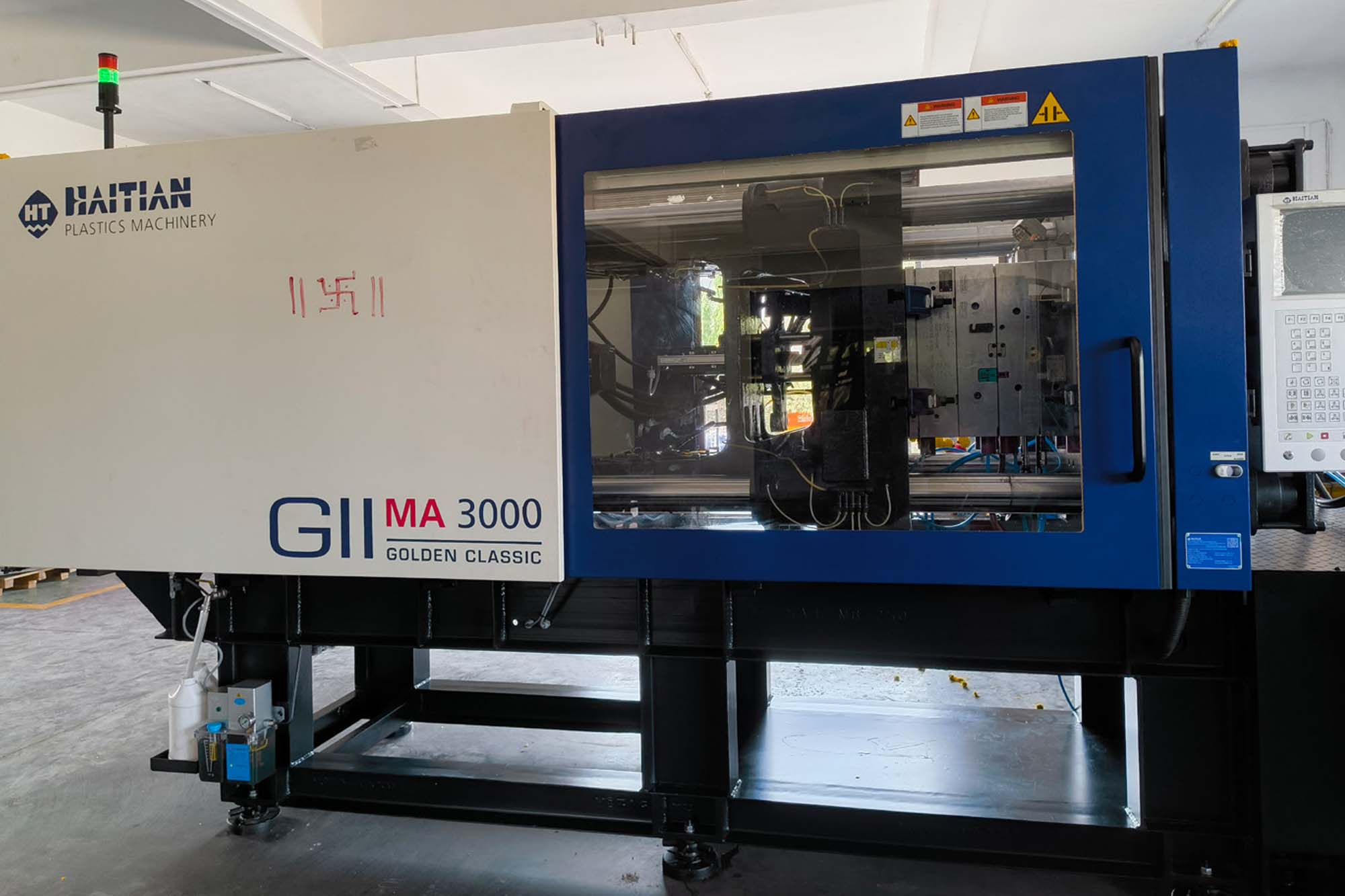

The elimination of logistical complexities and associated downtime is a significant time-saver. By having capabilities in-house, businesses bypass all transportation time, costs, and the inherent risks of damage during transit. The seamless transition from mould completion to initial moulding trials means less idle time for the project. Their state-of-the-art facility is designed for this operational efficiency, ensuring that once the tool is perfected, production can commence without unnecessary pauses.

Opting for a toolroom with an integrated moulding facility is a strategic decision that directly translates into substantial time savings throughout the product development lifecycle. Toolroom exemplifies this advantage, offering mould manufacturing, compression moulding, injection moulding and 3D printing under one roof.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.