SDTRONICS is adopting automation as per the needs of the hour

By Staff Report August 1, 2025 7:41 pm IST

Manufacturing operations change in response to increasing demands and evolving needs. Manojit Brahme from SDTRONICS shares that their production line has semi-automated and fully automated processes, depending on the complexity and volume of the product. What has automation done for them? Enhanced throughput, reduced rejection rates and more.

How has the demand for wires and cables evolved in recent years, and how has SDTRONICS adapted its manufacturing capabilities to meet these demands?

The wire and cable industry has witnessed a remarkable surge in demand due to rapid electrification, the accelerating shift towards electric vehicles (EVs), and large-scale infrastructure development across the country. To address this, we have expanded our product range and enhanced our technical capabilities to produce high-performance, application-specific cables that meet the requirements of various applications.

Our offerings have evolved from standard industrial cables to highly specialised harnesses and customised cable solutions for sectors like EV, renewable energy, factory automation, and smart infrastructure. We’ve also invested in modernising our production setup and adopting lean practices for flexibility and scalability.

Can you walk us through your production line? Also, what level of automation have you implemented, and how does it impact quality and output?

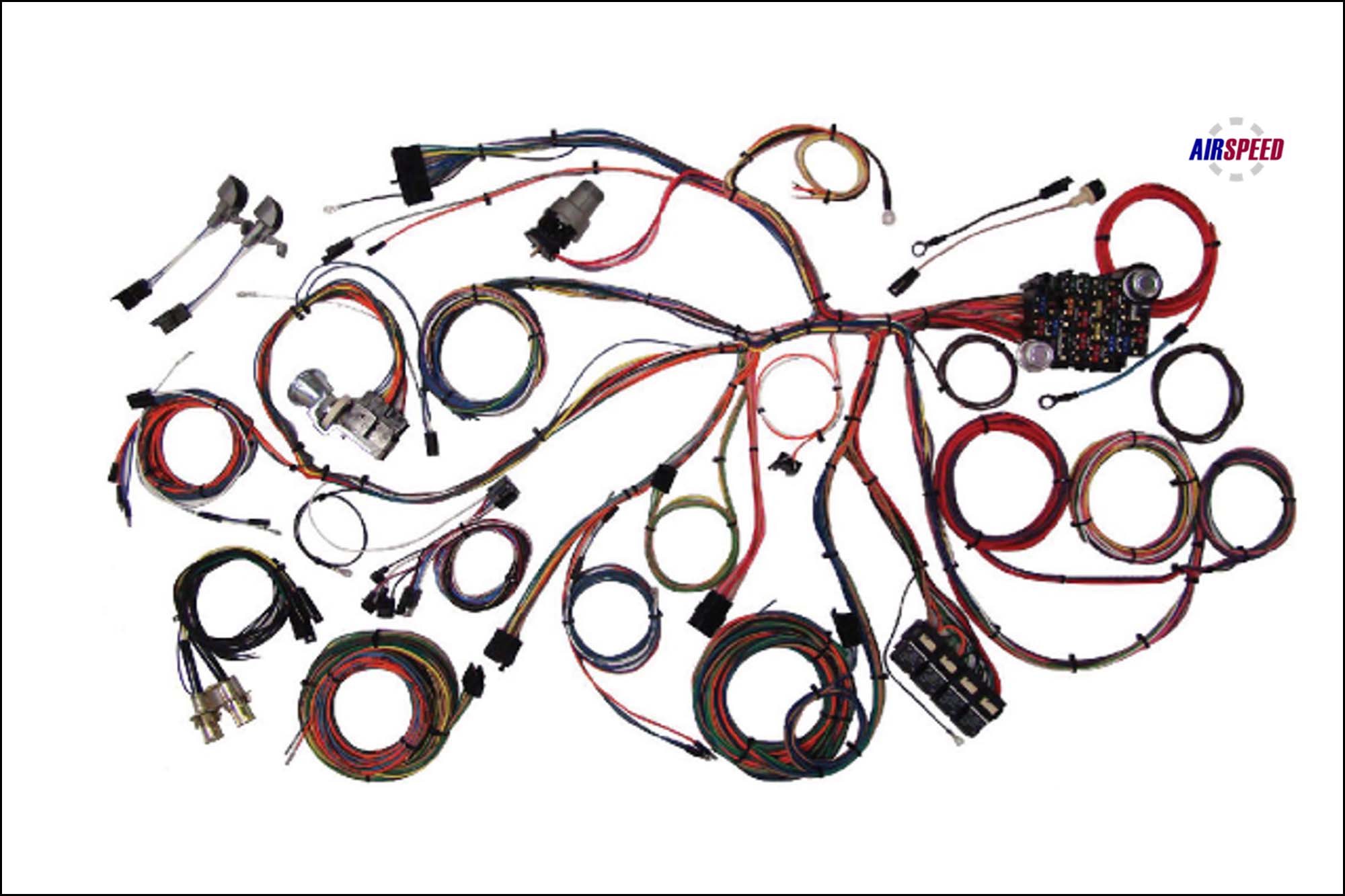

Our production line is a mix of semi-automated and fully automated processes, depending on the complexity and volume of the product. We have integrated precision cutting, stripping, crimping, and testing machines to reduce manual intervention and ensure consistent quality. For cable harnessing, we follow well-defined SOPs and use jig-based assemblies for accuracy.

Automation has enhanced our throughput and reduced rejection rates. It helps us fulfil just-in-time requirements with higher reliability. Our focus is on increasing speed while maintaining traceability and process control throughout the production lifecycle.

With the rising demand in the EV, renewable energy, and automation sectors, how are you adapting your manufacturing processes and product range to stay competitive?

We have diversified into manufacturing cables that meet the unique demands of EV manufacturing companies (high temperature, compact size, flexibility), solar applications (UV-resistant, low-loss conductors), and industrial automation (shielded, twisted pair, Profinet, Single Tech, etc.).

Our R&D team works closely with OEMs to co-develop solutions tailored to their evolving applications. We have also upgraded our insulation and sheathing lines to work with halogen-free, flame-retardant, and PUR/PVC compounds, giving us the flexibility to offer products that comply with global standards.

What quality assurance systems are in place at SDTRONICS to ensure compliance with national and international standards in wire and cable manufacturing?

Quality is at the core of everything we do. We are an ISO certified company. Additionally, we are ZED-certified, with a silver level of certification. This shows our commitment to sustainable and defect-free manufacturing.

Our QA process begins at the raw material stage, with rigorous testing for conductor purity, insulation quality, and mechanical properties. In-process inspections, electrical testing (including high-potential, continuity, and resistance), and final inspections ensure that every product meets applicable IS, IEC, or customer-specific standards. Calibration of instruments and regular audits are part of our quality control framework.

How are you addressing challenges related to raw material sourcing in today’s volatile market?

Raw material volatility is a reality we are well-prepared to handle. We have built strong relationships with Tier-1 suppliers, ensuring priority access and stable pricing to some extent. We also maintain safety stock levels and practice strategic procurement to mitigate price fluctuations and supply chain disruptions.

Our technical team constantly explores alternative materials and designs without compromising performance, allowing us to optimise cost and maintain delivery timelines for our customers.

What are your current priorities in terms of expanding or upgrading your manufacturing infrastructure? Are there any plans for localisation or capacity enhancement?

Our immediate focus is on capacity expansion and infrastructure upgradation. We are adding new lines for some of our key customers. A dedicated space is also being developed for cable harness manufacturing to meet the growing demand for exports and domestic sales.

Localisation is a key part of our strategy, especially for import-substitute products like moulded cables and custom cable assemblies. This reduces lead time and cost while aligning us with the “Make in India” vision. We are committed to building a future-ready manufacturing ecosystem that can serve diverse industry needs efficiently.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.