The critical importance of post-processing in AM

By Staff Report July 10, 2025 6:06 pm IST

Post-processing is an often overlooked step in additive manufacturing (AM) that helps manufacturers transform raw 3D-printed parts into high-quality, end-use components. This article explores its role in bridging AM with industrial applications.

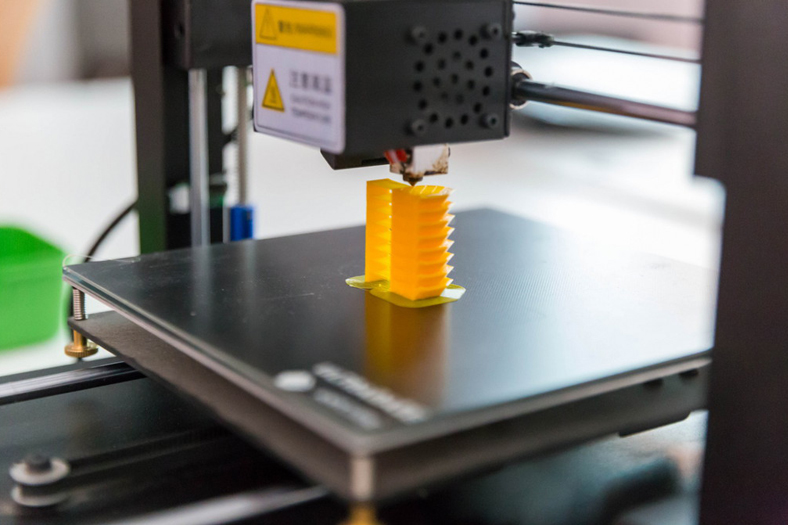

In additive manufacturing (AM), much focus is on the build process — the layer-by-layer creation of intricate, high-performance parts. Yet, it is not the printing process but what happens next that determines the true success of AM in real-world applications.

Post-processing is the often-overlooked step that transforms raw 3D-printed parts into functional, end-use components that meet the rigorous standards of many industries. While unfinished parts are suitable for many functional end-use applications, finishing opens up the possibility of many more end-use applications. In a time when AM is being pushed towards mainstream adoption, the importance of post-processing has become more relevant.

Bridging the gap between 3D printing and usability

While AM has revolutionised part design, enabling complex geometries and rapid iteration, the raw outputs from even the most advanced AM technologies still fall short of industry requirements. Parts often emerge from the build chamber with surface roughness, inconsistent mechanical properties, and residual powder or support structures that must be removed or refined before parts can be used. While AM enables direct part production, many industries require additional finishing steps to meet specific functional and aesthetic standards. The misconception that AM produces a final-use product in a single step has hindered its adoption, as companies often underestimate the necessity of thorough post-processing techniques to bring parts up to industry standards.

Industries that rely on precision components often require tight tolerances, smooth finishes, or enhanced material properties – needs that sophisticated post-processing helps address. In aerospace applications, for example, surface imperfections can impact aerodynamic performance, leading to inefficiencies or even failure in extreme conditions. Similarly, medical components require biocompatibility and sterility, which necessitate ultra-fine surface control to ensure that parts are safe for use in the human body. These industries cannot accept a part straight from the printer, no matter how groundbreaking the chosen AM process may be. Optimising the transition from printing to usability is an ongoing refinement in the AM industry today.

Post-processing as the key to industrial adoption

Post-processing in AM is a multi-faceted process, requiring a tailored approach depending on the material, part function, and final application. Support removal and cleaning are crucial first steps, as many AM processes rely on temporary structures to maintain complex geometries during printing. De-powdering is necessary to eliminate residual material affecting dimensional accuracy in powder-based processes such as SLS and MJF. Surface finishing and smoothing processes follow, as the raw surface of AM parts often contains stair-stepping effects or rough textures that impact aesthetics and function.

Techniques such as vapour smoothing, vibro-polishing, and media blasting help refine surfaces to production-quality standards. Beyond mechanical refinement, dyeing and coating techniques contribute to aesthetics and functionality, enabling colour customisation, anti-microbial treatments for medical applications, or heat-resistant coatings for various industrial components.

Overcoming Barriers to large-scale Adoption

Despite AM’s advancements, the lack of standardisation in post-processing remains one of the biggest hurdles to full-scale adoption. Unlike traditional manufacturing, where surface finishing and tolerances are well understood, AM post-processing still requires trial and error and often remains labour-intensive. This creates challenges in scalability and cost-effectiveness, particularly when companies are looking to transition from prototyping to full production.

There is a pressing need for automated, repeatable, and cost-efficient finishing techniques that ensure AM parts meet industry standards without excessive manual intervention. Until post-processing can be streamlined efficiently, AM will struggle to compete with traditional manufacturing methods in higher-volume production applications.

Another critical consideration is the perception of AM in mainstream manufacturing. While AM adoption is growing, some companies remain hesitant to adopt AM due to concerns that the technology is not yet capable of delivering end-use components at scale. This perception is based on inadequate post-processing resulting in AM parts failing to meet industry expectations. However, the reality is that AM has already demonstrated its potential in several sectors, provided that post-processing is integrated effectively. Companies that invest in advanced post-processing solutions are seeing AM successfully transition beyond prototyping.

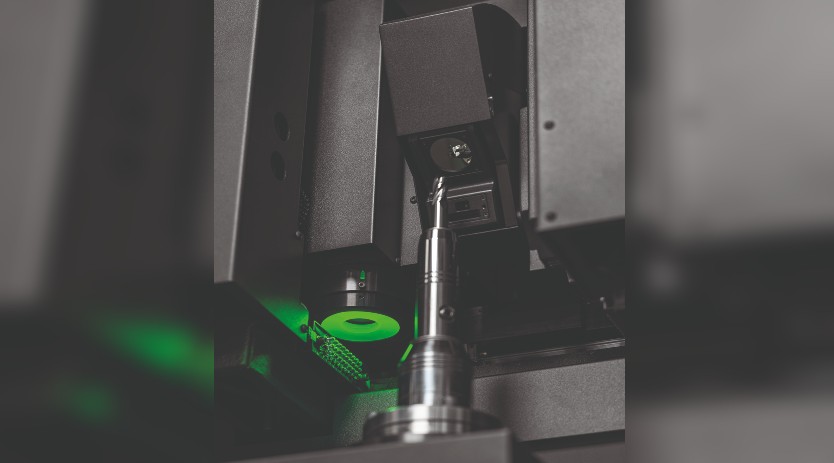

The role of automation and innovation in post-processing

The future of AM depends on tackling post-processing challenges. Automation can make post-processing more viable for mass production. Emerging technologies offer solutions, such as sophisticated software-driven surface analysis systems that ensure consistency, and automated de-powdering stations that reduce manual labour. New finishing materials and coating applications will also expand AM’s potential, allowing for broader adoption in industries that demand specific material properties. Investment in research and standardisation efforts will help the post-processing keep up with the rapid evolution of AM technology itself.

A new mindset: Post-processing as an integral part of AM

Companies focus their AM strategies solely on the printing process, overlooking the role of post-processing. True production-grade AM can be achieved with post-processing done from the outset and integrated into the design phase rather than treated as an afterthought. Design for Additive Manufacturing (DfAM) should incorporate post-processing considerations, ensuring that parts are optimised for finishing techniques that enhance performance rather than limit it. Companies that fail to factor in post-processing from the beginning risk encountering delays, increased costs, and quality issues that could have been mitigated through better planning.

The next major innovation will be the technologies that refine and finish parts after the build. The industry must shift its mindset. For many applications, AM doesn’t stop when the printer does – post-processing is often the key to meeting final-use requirements. Post-processing is not a bottleneck as some would say, it is the bridge that connects the promise of AM with real-world functionality. If AM is to move beyond prototyping and into full-scale production, it’s time to elevate the conversation about finishing technologies and their role in the future of digital manufacturing. The challenge now is making AM parts work seamlessly in their intended applications.

Embracing the Future of AM with a Holistic Approach

Companies adopting AM at scale must take a holistic approach with a robust post-processing strategy. The industry is at a tipping point, where those who prioritise post-processing will lead in pushing AM into full-scale production.

Authored by – Sasha Bruml & Felix Manley, Co-Founders, 3D People

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.