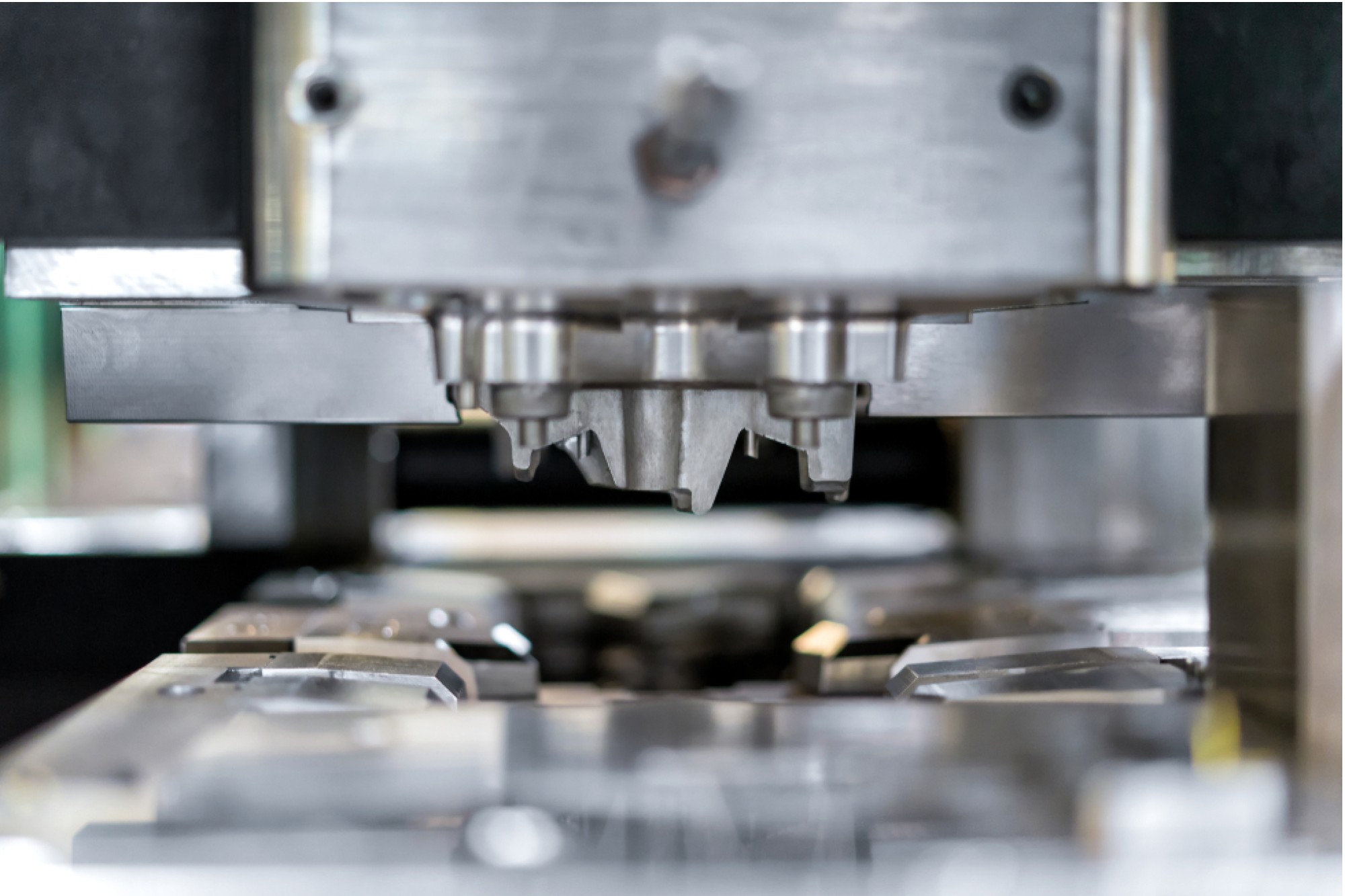

Godrej & Boyce introduces connected Die casting Die for parameter monitoring

By OEM Update Editorial March 27, 2024 7:17 pm IST

Smart Connected Die casting Die improves foundry efficiency with increase in die life by 10% and lowers per piece cost by another 10 percent.

Godrej & Boyce, the flagship company of the Godrej Group, announced that its business Godrej Tooling unveiled the Smart Connected Die casting Die, a patented technology that revolutionizes the monitoring of real-time die parameters. This innovative solution aims to reduce breakdowns by alerting non-conformance and predicting failures in die casting production. This milestone in Indian die casting offers an indigenous solution that boosts efficiency. With a 10% increase in die life, a 10% cost reduction per piece, and fewer rejections, it signals a significant industry advancement.

Traditional die casting monitoring methods have long been constrained by their reliance solely on machine-side parameters, overlooking critical die-related factors essential for ensuring consistent part quality. Recognizing this gap, Godrej Tooling developed the Smart Connected Die casting Die. The system captures temperature and pressure parameters within the die, crucial for maintaining consistent quality. Historically, production continued with faulty parts until there were manual inspections or critical breakdowns. This new technology addresses the issue by offering real-time insights and ‘traceability’ into die performance, enabling early detection of problems, resulting in reduced downtime, enhanced efficiency, and heightened productivity for manufacturers. This innovative solution is poised to benefit a wide range of industries where consistent part quality and production efficiency are paramount. This has been built entirely indigenously, with critical parts designed to perform in challenging foundry conditions having gone through multiple iterations. It is providing an answer to the need of foundries to become Industry 4.0 enabled.

Pankaj Abhyankar, Senior Vice President & Business Head, Godrej Tooling, said, “By seamlessly integrating real-time monitoring, proactive alerts, and cloud-based accessibility, we are not just optimizing die casting processes, but rather fundamentally reshaping how manufacturers approach production. Alongside improving individual components, this will empower entire industries to embrace smarter, more adaptive methodologies that prioritize quality, reliability, and sustainability. As we continue to bridge the gap between traditional manufacturing and cutting-edge technology, the potential for transformative change across the manufacturing landscape is limitless.”

This technology provides instant insights into die thermal conditions and machine parameters for each shot, ensuring that deviations are identified and promptly addressed. It enables remote access to production conditions through cloud connectivity and boasts data analysis capabilities for efficient root cause analysis. The Smart Connected Die Casting Die collects process parameters directly from the machine or dedicated sensors on the die casting equipment and side cores for each shot. This data is then uploaded to the Cloud server via Wi-Fi or SIM card at specified intervals. The patent titled, “A System and a method for monitoring operating parameters of a Die casting System” has been granted to the business for the period of 20 years.The Cloud system processes the information, presenting it in graphical or tabular formats on web pages accessible via various devices. Instant alert SMS notifications are sent if any parameter exceeds its limit.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.