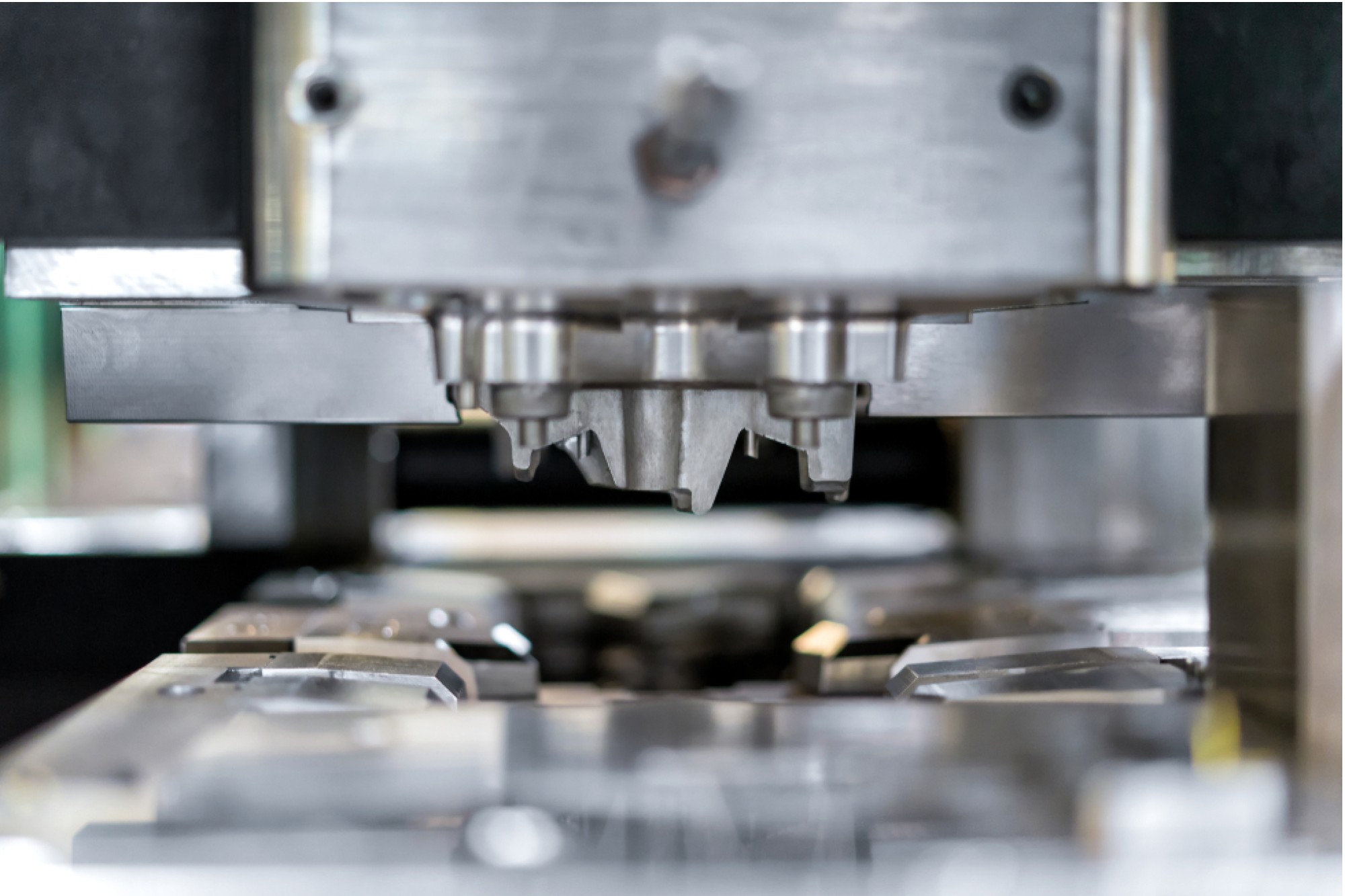

Pattern creation and core manufacturing in die and moulds are advancing

By OEM Update Editorial January 31, 2024 7:36 pm IST

Swapnil Patil delves into crucial die and mould manufacturing aspects, materials selection, and precision-enhancing technologies. He highlights that among the various manufacturing processes, injection moulding is extensively used to produce components in various industries, including automotive, consumer products, electronics, and more.

What are the key factors influencing the selection of materials for manufacturing dies and moulds?

Mould material selection is a critical factor in manufacturing dies and moulds. It depends upon various parameters, such as the raw material of the finished part, manufacturing quantity, and the desired quality of the finished parts. The choice of mould material holds importance as it directly impacts factors like mould life and wear and tear, especially after a certain number of cycles.

What technologies are utilised in the die and mould industry to improve production efficiency and quality?

Mould manufacturers are looking towards 5-axis machining, replacing the 3-axis machining concepts. This helps them reduce manufacturing time, reduce setups, and get more accurate moulds. Online measuring systems are being implemented to check and inspect moulds directly on CNC machines, enabling quick corrections to be made as needed.

Could you elaborate on the current manufacturing trends for customising moulds in producing automotive components?

Many automotive components were commonly made from heavy iron and steel alloys. Both of which are strong but heavy materials. However, advancements in manufacturing technologies have empowered automotive companies to substitute these metal parts with new materials such as aluminium, magnesium, high-performance plastics, carbon fibre, and other composites. These alternatives are lighter yet provide equivalent strength and stiffness, allowing manufacturers to fulfil consumer demands.

With new CAD/CAM software tools, how is 3D printing leveraging component and equipment part manufacturing?The new mould design software has simplified core, cavity, and electrode extraction. Some software even provides material flow analysis within moulds. The new CAM software has streamlined the programming of toolpaths for moulds. It autonomously selects tooling from libraries. This results in faster and more efficient program generation. Additive manufacturing or 3D printing is gaining popularity in producing new components, as well as in research and development, medical applications, and the aviation and defence sectors.

This technology is widely employed in the mould industry, particularly for pattern creation and core manufacturing in the casting sector, as well as for developing and testing new parts.

How does the integration of robotics impact the manufacturing of plastic components?

Nowadays, robots are extensively utilised in the die and mould industry for handling parts, assembling plastic components, deburring, ultrasonic welding, and more. This technology significantly minimises the need for manual intervention, enabling the production of components with full automation and reducing the occurrence of rejects.

A promising opportunity in metal injection moulding is emerging, indicating a bright future for the die and mould industry.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.