Inside the assembly lines of Omega Seiki Mobility

By Staff Report June 17, 2025 12:06 pm IST

The OEM Update team went on a guided tour at the sprawling premises of Omega Seiki Mobility’s state-of-the-art manufacturing facility for electric three-wheelers—both passenger and cargo variants—located in Chakan, Pune. Established in 2022, this is the company’s fourth plant overall and first outside Haryana. Embracing advanced manufacturing technologies, the Pune facility has a production capacity of 500 vehicles per month, translating to 6,000 cars annually, with plans to scale this up to 30,000 cars per year.

The strategic intent behind setting up this plant in Pune was to better serve clients in western and southern India. This unit rolls out the entire range of Rage electric vehicles, including passenger and cargo three-wheelers. Omega Seiki Mobility’s growing 3W portfolio features Rage Rapid, Rage Frost, and Rage Swap models.

Omega Seiki Mobility’s Chakan manufacturing facility is over 50,000 square feet and employs approximately 250 people. It develops and manufactures the Rage+ series and the passenger electric vehicle Stream.

The Pune plant represents a significant investment of approximately ₹40 crore, with OSM outlining plans to invest an additional ₹190 crore over the next three years. The plant utilises automated manufacturing systems for logistics, material handling, fabrication, painting, assembly, and quality assurance.

The Pune plant is strategically positioned in Omega Seiki Mobility’s long-term growth vision, particularly as it looks to scale its manufacturing capabilities and expand its footprint in western India. Being close to major automotive and industrial hubs such as Chakan, Mumbai, and Nashik, this location allows for seamless supply chain integration, access to a skilled workforce, and proximity to key OEM and Tier 1 partners. The plant is designed to cater to increasing demand in both domestic and export markets.

The Pune facility also helps deepen collaborations within the Chakan industrial ecosystem, where the parent company of OSM operates plants focused on steel and auto components. This proximity to internal capabilities and external partners enhances R&D efforts and enables faster prototyping, testing, and refinement of electric three-wheeler products, both passenger and cargo. It allows OSM to build localised products and deliver solutions tailored to evolving last-mile and intra-city transport needs.

Zero-defect manufacturing

The facility focuses on zero-defect manufacturing and begins with building strong processes and disciplined quality control systems. Every vehicle goes through multiple quality gates during assembly, where rigorous checks are conducted at each stage. OSM follows a strong SOP-driven approach supported by visual management systems and poka-yoke mechanisms to eliminate human error. The internal audit systems and end-of-line testing were in place to ensure that no vehicle left the plant without meeting strict quality benchmarks.

OSM has heavily invested in building a skilled and quality-conscious workforce. Regular training, cross-functional skill development, and real-time feedback loops help the teams identify and correct even the smallest deviations early in the process. This combination of process discipline, preventive quality measures, and a well-trained team forms the backbone of a zero-defect approach and helps OSM deliver reliable and durable electric vehicles.

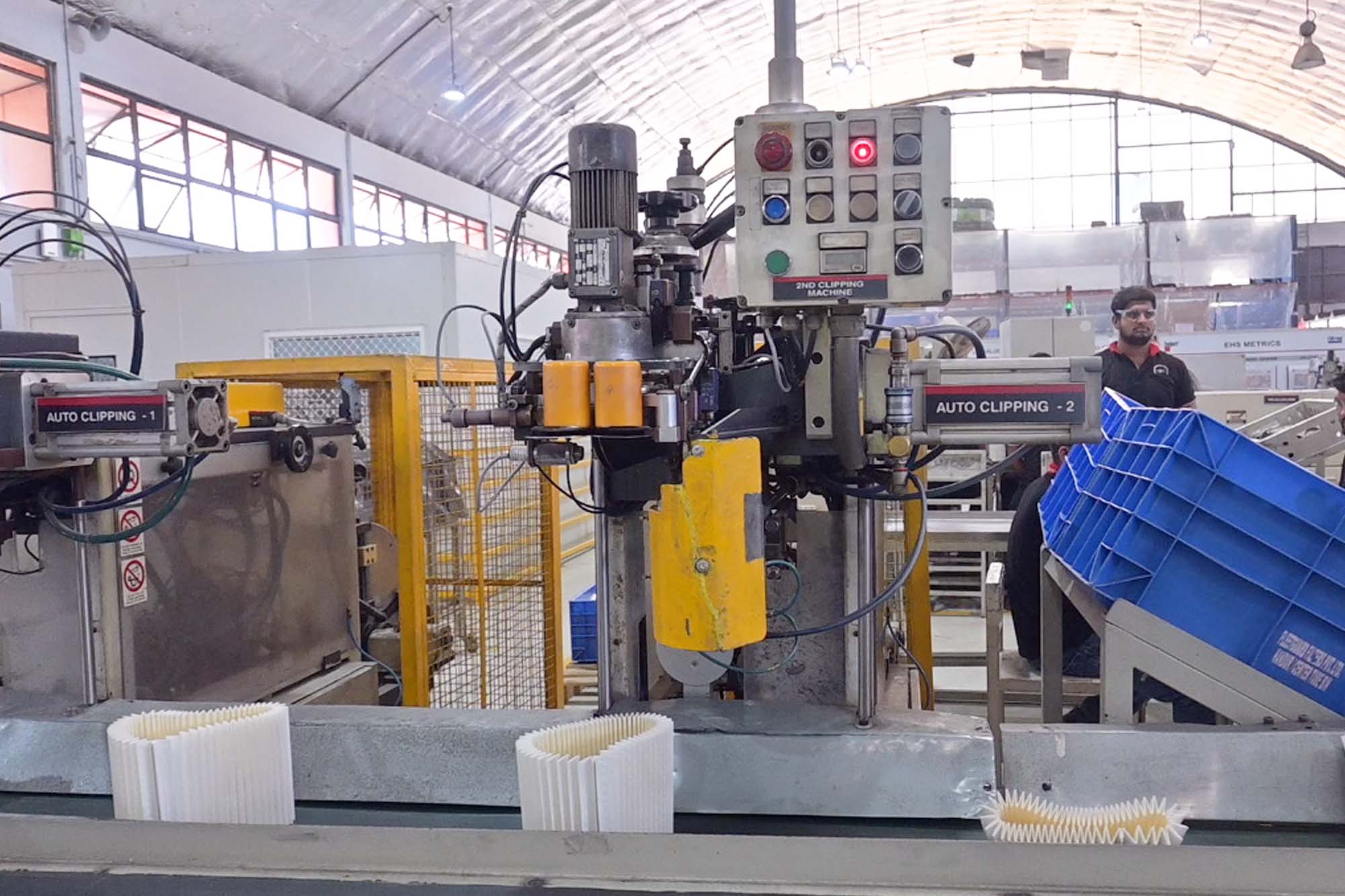

Automation and robotics for seamless production

While many manufacturers opt for fully automated setups, OSM has consciously integrated selective automation in areas requiring precision and consistency while still relying heavily on a well-trained workforce for core assembly and quality operations. This combination was seen as maintaining flexibility, adapting to product changes, and ensuring high levels of craftsmanship in every vehicle produced.

The EV component assembly lines used a combination of skilled manpower and selective automation. Repetitive and precision-driven tasks like torquing and battery pack sealing were automated, while trained workers handled assembly, inspection, and adjustments. This setup helps OSM maintain quality, reduce rework, and speed up turnaround times. It also keeps the system flexible for new product variants and design changes.

Battery production and assembly

OSM is the only company offering all three battery options—fixed, fast, and swappable—across its product range. It caters to a wide spectrum of customer needs, from fleet operators to last-mile delivery services. One of the key innovations is OSM’s proprietary fast-charging technology, which enables a full charge in just 15 minutes. This breakthrough is particularly valuable for commercial applications where vehicle uptime is critical.

Additionally, OSM’s in-house developed battery platform, OSM NRG, delivers the widest range in its segment—up to 300 kilometres on a single charge. This reduces range anxiety and enhances operational efficiency. They have also partnered with cell technology providers and energy companies for the high performance and safety of battery systems.

Battery recycling technology

Battery recycling is a key part of OSM’s sustainability vision. To ensure the safe, responsible, and efficient recycling of end-of-life batteries, OSM has partnered with Attero, one of India’s leading e-waste and lithium-ion battery recycling companies. This collaboration helps OSM recover valuable materials such as lithium, cobalt, and nickel, reducing dependency on raw material imports and minimising environmental impact.

At the Pune plant, dedicated systems are in place to safely collect, store, and dispatch used batteries for recycling. Employees are trained to handle batteries at the end of their life cycle, ensuring they are properly categorised for second-life use or recycling.

Green and sustainable initiatives

Sustainability is a key focus at OSM’s Pune facility. They are working toward integrating solar-powered systems across its plants to reduce reliance on conventional energy sources. The goal is to transition a significant share of energy consumption to clean, renewable sources and lower the overall carbon footprint.

This initiative is part of a broader plan to build a green manufacturing ecosystem. As an electric vehicle manufacturer, aligning production processes with clean mobility goals is essential. The gradual shift to solar energy is expected to play a major role in supporting future growth.

Modular or scalable manufacturing setups for rapid capacity expansion

Modular and scalable manufacturing is central to OSM’s operations. The Pune plant is designed for phased capacity expansion without disrupting existing production. A cell-based layout allows quick replication and scale-up as demand increases. This setup supports rapid response to market requirements for new model launches or higher production volumes.

Additional land next to the current facility will help key suppliers located within the Chakan industrial belt ensure uninterrupted logistics and component availability.

Skill and upskilling

People are OSM’s greatest asset, and continuous skill development is central to OSM’s manufacturing excellence. OSM runs structured training programs in collaboration with technical institutes, where employees are trained in EV-specific systems such as battery management, high-voltage safety, and diagnostics. On-the-job training, classroom sessions, and hands-on workshops are regularly conducted to ensure that the workforce is equipped with foundational knowledge and practical exposure to the latest technologies.

In addition, they follow a “train the trainer” model to ensure efficient knowledge cascades across teams. As new processes, tools, or equipment are introduced, speciality training modules are rolled out immediately so employees are never left behind. Cross-functional learning is encouraged across the plant to promote agility and adaptability.

Future

With the expansion plan of producing 3,00,000 vehicles annually, OSM has acquired additional land adjacent to the current facility. The existing plant layout has been planned to support phased expansion, and this new space will allow them to add new assembly lines and infrastructure.

Another advantage of OSM is its strong ecosystem in the Chakan industrial belt. Many key suppliers and logistics partners are located nearby, ensuring smooth coordination and faster turnaround times. This proximity minimises supply chain disruptions and allows for quick scalability.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.