Making 3D printing easy, affordable, and available to everyone

By Staff Report July 1, 2025 4:58 pm IST

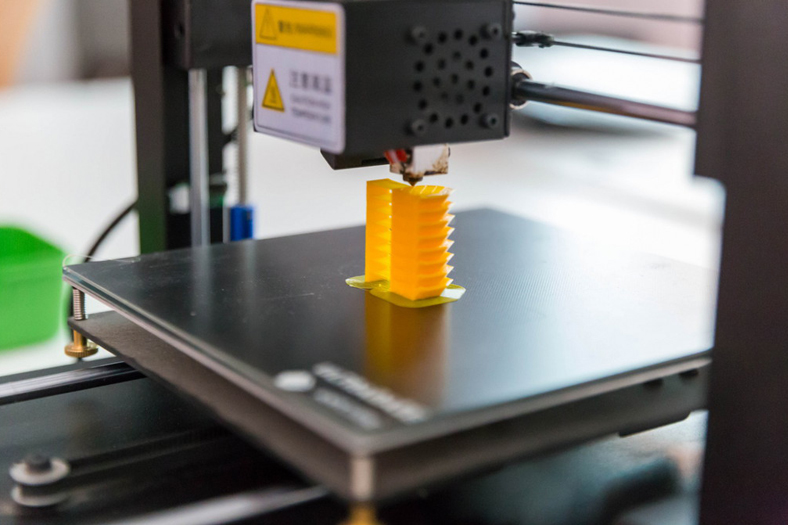

3D printing is about speed, personalisation, and creativity, and that’s exactly where the future of Indian manufacturing is headed. Recognising this potential, Rahul Chandalia founded WOL3D to make 3D printing accessible to the masses, allowing users to create faster, more easily, and in ways previously unimaginable.

What inspired you to start WOL3D, and how has the journey evolved so far?

The idea behind WOL3D began with a moment of curiosity. A few years ago, I came across 3D printing at a tech event and was instantly drawn to it. It wasn’t just the machines that caught my attention, but the thought of how this technology could help people create things on their own faster, easier, and in ways we hadn’t imagined before.

That’s how WOL3D started with a simple goal to make 3D printing more accessible and useful for everyday users. Over the years, we’ve grown step by step. Today, we offer quality products and help build awareness, provide support, and create a space where people can explore and express their ideas through 3D printing.

What started as a passion has now evolved into a thriving community, and we’re excited about what’s ahead.

With the growing demand for localised supply chains, how is your company addressing the need for faster, agile prototyping within India?

At WOL3D, we believe 3D printing is a key enabler for faster and smarter product development. As the focus on localised supply chains grows, we’re helping businesses bring their ideas to life quickly and efficiently right here in India.

Our technology enables the creation of prototypes within days, making the design-to-product journey smoother and more flexible. This approach supports innovation across various sectors, including manufacturing, healthcare, education, aerospace, entertainment, and design.

We’ve also built a strong presence across the country with service teams and experience centres, so access to our solutions is always within reach.

How are you integrating AI or machine learning into design validation or testing during the printing phase?

AI and machine learning enable the 3D printing machine to follow instructions and serve as a smart innovation partner. At WOL3D, we envision a future where printers learn from every print, improve with time, and help users achieve the best results without trial and error.

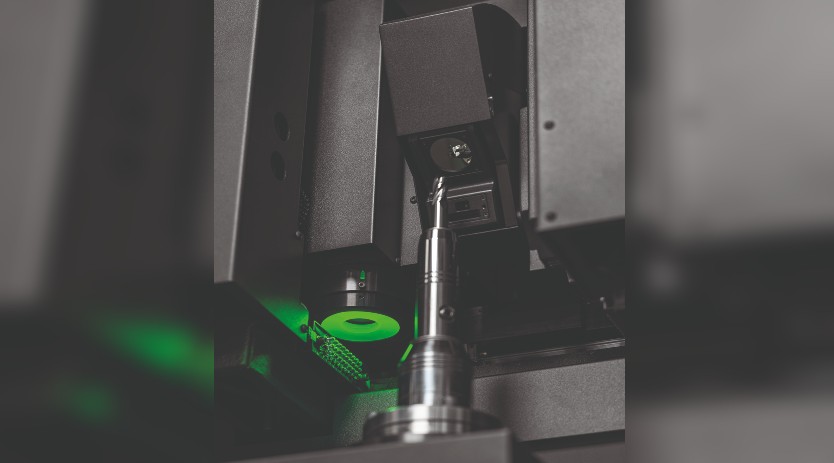

We’re already exploring ways to use AI for design checks, error detection, and print optimisation. This means the system can suggest changes to improve strength, surface finish, or material use before printing even begins. During the printing process, AI can monitor progress in real-time, identify any irregularities, and help ensure consistent quality.

Our goal is to make 3D printing more intelligent, reliable, and user-friendly.

With rising demand for shorter product development cycles, how are you enhancing speed-to-market for your customers?

Our 3D printing solutions accelerate every stage of development, from prototyping to final production.

We provide fast, on-demand printing that allows customers to test, modify, and finalise their designs in a matter of days. This flexibility is a big advantage for start-ups, designers, and businesses that want to launch products faster without compromising on quality.

We have also built a strong support system with expert guidance, training, and service centres across India. This ensures our clients get quick help, reliable advice, and the tools they need to stay ahead.

How is WOL3D making 3D printing more accessible to individuals and small businesses?

Our core mission has always been to make 3D printing easy, affordable, and available to everyone, not just large industries. We have designed our products and services, keeping individuals, creators, educators, and small businesses in mind.

We offer a wide range of plug-and-play machines that are beginner-friendly, cost-effective, and backed by strong customer support. Whether someone is building a prototype, starting a creative business, or exploring new ideas, we make sure they have the right tools and guidance.

We have also set up experience centres, training programs, and workshops across India to create awareness and build confidence around using 3D printing.

How is WOL3D helping bridge the gap between theoretical STEM education and practical tech skills?

One of our key priorities at WOL3D is to make technology more hands-on for students. We believe that STEM education becomes truly impactful when learners can move beyond theory and apply their knowledge in practical settings.

We have introduced 3D printing at training centres as a learning tool. When students design and print their projects like models, working parts, or creative prototypes, they gain real-world experience while understanding the science behind it.

To encourage early learning, we also run ‘Summer Champ’ classes every May, where children and teens are introduced to 3D printing in a fun, engaging way. It’s incredible to see young minds pick up complex concepts so quickly when they get to build things themselves.

How do you see 3D printing shaping the future of manufacturing in India over the next 5–10 years?

Over the next decade, I believe 3D printing will play a key role in reshaping India’s manufacturing landscape. At WOL3D, we’re seeing this shift first-hand. With the launch of our BRAHMA 3D Lab, equipped with over 200 advanced printers, we are doing mass customisation and rapid prototyping at scale. We are also seeing a growing appetite from SMEs, startups, and home creators exploring flexible manufacturing alternatives. 3D printing will empower smaller businesses to innovate without requiring heavy infrastructure as India advances with skilling programs and Make-in-India initiatives.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.